What is Polyamide?

Polyamide, often abbreviated as PA, is a general synthetic polymer containing amide groups that are repeated and interconnected by amide links. It was originally used as a raw material for manufacturing fibers. Later, PA became a widely used engineering plastic in the industry due to its toughness, wear resistance, self-lubrication, and wide operating temperature range.

Polyamide was first developed by DuPont in the United States, and it was industrialized in 1939. In the 1950s, it began to develop and produce injection-molded products to replace metals to meet the requirements of lightweight and cost-reducing needs. PA has good properties, including mechanical properties, heat resistance, wear resistance, chemical resistance, and self-lubrication, and has a low friction coefficient, a certain degree of flame retardancy, and is easy to process. There are many varieties of PA, including PA 6, PA 66, PA 11, PA 12, PA 46, PA 610, PA 612, PA l010, etc.

Properties of Polyamide

Key characteristics and properties of polyamide include:

Excellent mechanical properties: Nylon has high mechanical strength and good toughness.

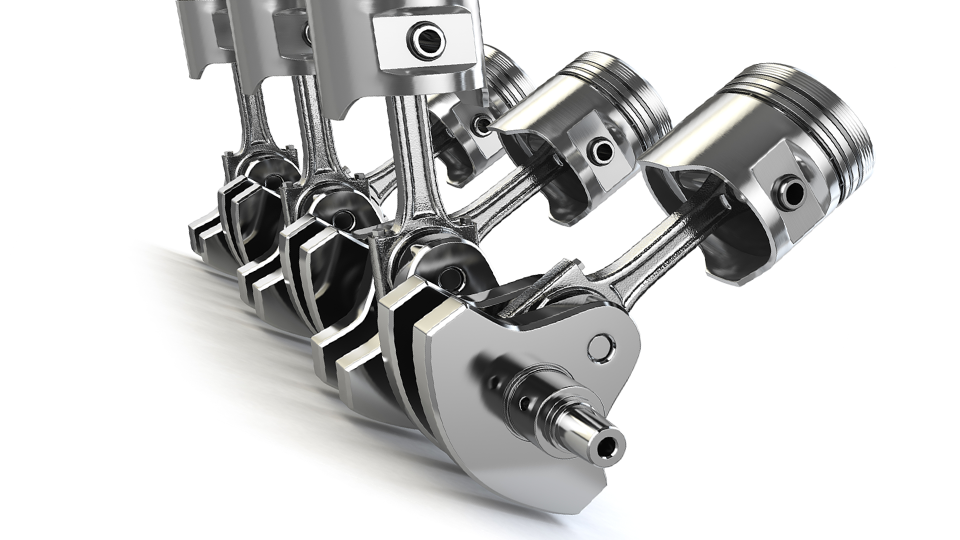

Good friction resistance: Nylon has good self-lubrication and a low friction coefficient, so it has a long service life as a transmission component.

Excellent heat resistance: Highly crystalline nylons, such as nylon 46, have a high heat deformation temperature and can be used for a long time at 150 °C. After PA66 is reinforced with glass fiber, its heat deformation temperature reaches more than 250 °C.

Good water absorption: Nylon has high water absorption, and saturated water can reach more than 3%. This property may affect the dimension stability of the parts.

What is Polyester?

Polyester is an umbrella term for fabrics containing one or two ester linkages in every repeat unit of their main chain. Generally speaking, polyester usually refers to polyethylene terephthalate (PTT).

The history of polyester fiber can be traced back to 1894 when Vorlander used succinyl chloride and ethylene glycol to make low-molecular-weight polyester. In the following decades, different types of polyester were synthesized, but early polyesters were easily soluble in water due to their low molecular weight and low melting point, making them unsuitable for textile use. It was not until 1941 that Whinfield and Dickson in the UK synthesized polyethylene terephthalate (PET). In 1953, the United States first built a factory to produce PET fiber. With the development of organic synthesis, polymer science, and industry, we have developed a variety of practical PET fibers with different characteristics in recent years. For example, polybutylene terephthalate (PBT) fiber and polytrimethylene terephthalate (PTT) fiber have high elasticity, and fully aromatic polyester fiber has ultra-high strength and high modulus.

Properties of Polyester

Key characteristics and properties of polyester include:

High strength: The strength is 4~7cN/dtex in a dry state and slightly decreases in a wet state.

Moderate elongation: Elongation at break is generally 20%~50%.

High modulus: Among synthetic fibers, polyester has the highest initial modulus, which can be as high as 14~17 GPa. This makes polyester fabrics dimensionally stable, not easy to deform and lose shape, and the pleats last long.

Acid resistance: Polyester is very stable to acids (especially organic acids). After being immersed in a 5% hydrochloric acid solution at 100°C for 24 hours or in a 70% sulfuric acid solution at 40°C for 72 hours, its strength is not lost.

Comparison of Polyamide and Polyester

Polyester and polyamide are two different types of materials with some differences, including the following aspects:

Chemical structure: Polyester is made by the polymerization reaction of polyester compounds, in which the ester group is the main structural unit. Polyamide is made by the polymerization reaction of polyamide compounds, in which the amide group is the main structural unit. The different chemical structures of the two lead to differences in their properties and applications.

Physical properties: Polyesters generally have higher strength and stiffness, while polyamides generally have higher toughness and impact resistance. Polyesters perform better in strength and are suitable for applications requiring higher mechanical properties, while polyamides perform better in toughness and are suitable for applications requiring impact resistance.

Heat resistance: Polyesters have relatively low heat resistance and are usually used at lower temperatures, while polyamides have higher heat resistance and can maintain stability at higher temperatures. Polyamides generally have higher glass transition temperatures and heat deformation temperatures and are suitable for applications in high temperature environments.

Hygroscopicity: Polyesters have certain hygroscopicity, while polyamides generally have lower hygroscopicity and can maintain more stable dimensions.

Application areas: Due to their different performance characteristics, polyesters and polyamides differ in their application areas. Polyester is widely used in composite materials, construction, automobiles, electronics, coatings, etc. Polyamide is often used to prepare heat-resistant, wear-resistant, and chemical-resistant products, such as plastic parts, fibers, and coatings.