Quality Is The Most Important Thing For Us!

- Fully inspected before delivery

- ISO9001 quality system certified

- We promise to be responsible for any defects and free change

Rigorous Supply Chain Management

We believe that only a complete workflow is an effective means to ensure quality.

Rigorous Supply Chain Management

Both self-operated and cooperative suppliers must comply with our manufacturing and quality control standards; Strict selection of suppliers: only 1 out of 6 applications can pass the partner recruiting process; Upstream and downstream coverage: strict control of the source of materials, and qualified surface treatments.

Professional Technical Review

Our engineering team performs a technical assessment of your parts design before production. We give feedback to the customers on the material, surface finish, structure, process, and other details of your 3D and 2D drawings to minimize pitfalls.

Well-Monitored Production Process

Your parts are to be machined in strict accordance with the standard process flow; Mass production after prototyping is only carried out after passing the FAI report; IPQC is carried out during the production process to ensure that each process is correct.

All Parts Fully Inspected

Our dedicated QC team follow strict quality control protocols to inspect all parts before shipping. A few types of test reports can be provided if required.

Quality Inspection Equipment

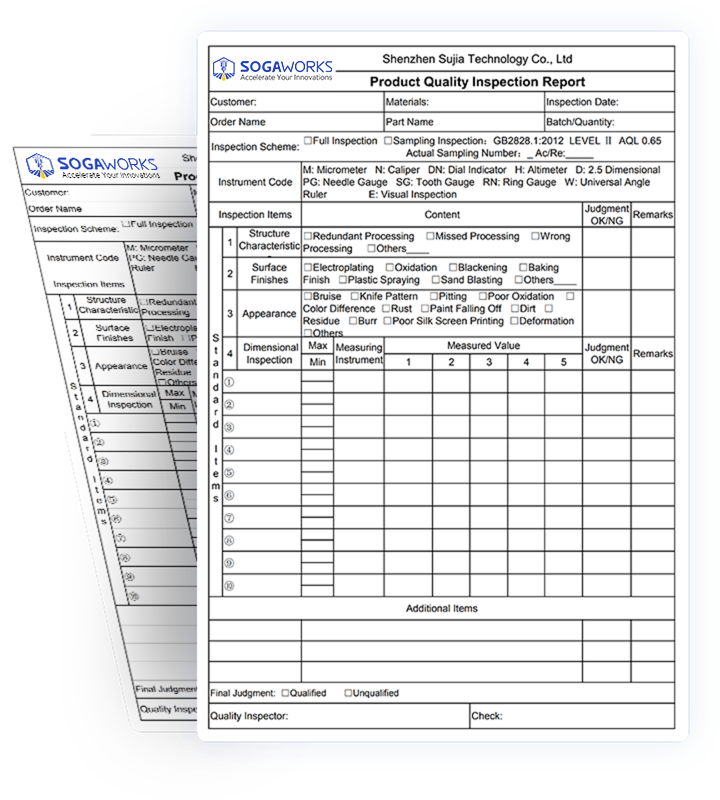

QC Report

Multiple QC reports are available on your demand.

- Standard QC Card

- Material Report

- Dimensional Check Report

- First Article Inspection Report

- Hardness Test Report

- Salt Spray Test Report

- CMM Inspection Report

- Self-Defined: Provide on Your Demand

Quality Inspection Equipment

What Our Customers Say

It was an amazing experience to work with SogaWorks people. They are very professional and caring and keep up smooth communication over our outsourced parts production. We will continue to partner with their service for future projects.

We have lots of projects for small quantity parts. SogaWorks has always treated our requests fairly. What is more, they provided us with valuable technical feedback. We really appreciate their genuine desire to help.

Postdoctoral Scholar, Stanford University

SogaWorks demonstrates professionalism. They enabled our purchasing process at ease. We don't have to juggle around managing various suppliers. You save the day. Great job!

Purchasing Specialist, Panasonic China

We would like to express our thanks for your down-to-earth support on our rush orders. Our requirements were rigid and the delivery deadlines were tight. Yet, all orders have been delivered perfectly. This is a team that can take challenging jobs.

Project Manager, HP