Custom CNC Milling Service

SogaWorks offers top-notch CNC milling services for rapid prototypes and low-to-large volume parts!

- Tight tolerance up to ±0.005mm

- 3, 4, 5 axis CNC milling for complex geometries

- A broad range of metals, plastics available

- Affordable, reliable solutions with fast turnaround

Start A CNC Milling Quote

STEP I STP I SLDPRT I PRT I IPT I DWG I PDF I DXF I ZIP I RAR

All drawings are secure and confidential.

Precision CNC Milling Capabilities

At SogaWorks, our CNC milling services offer higher quality and accuracy. Using advanced 3-axis, 4-axis, and 5-axis CNC machines, We handle complex parts with a tight tolerance of ±0.005mm. We provide a wide of material options, including metals, plastics, and composites, delivering reliable, cost-effective solutions with fast turnaround times.

3 axis CNC Milling

3-axis CNC milling is a cost-effective option for simple designs but remains accurate. 3-axis cnc milling provides precision milling by moving along 3 perpendicular axes: X, Y, Z.

4 axis CNC Milling

4-axis CNC milling offers enhanced precision by adding a rotational axis to the standard 3 axes. It enables ease of milling complex surfaces and tighter tolerances.

5 axis CNC Milling

5-axis CNC milling services offer both 3+2-axis machines and con 5-axis machines. The 5-axis enables the milling of complex, multi-dimensional parts with the highest precision and efficiency.

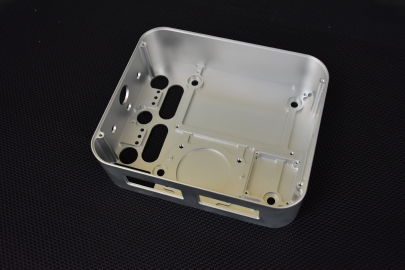

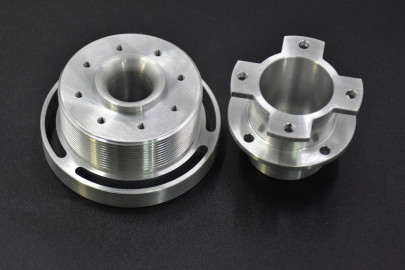

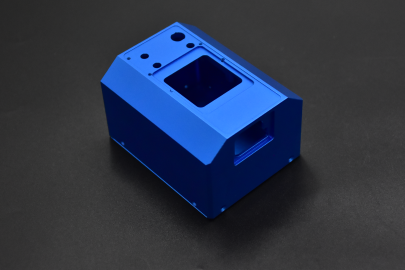

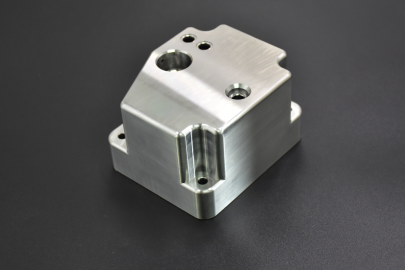

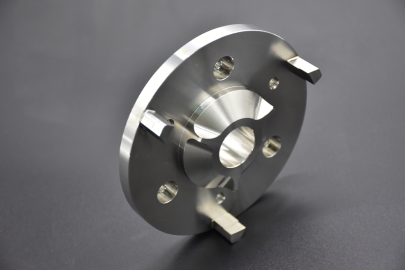

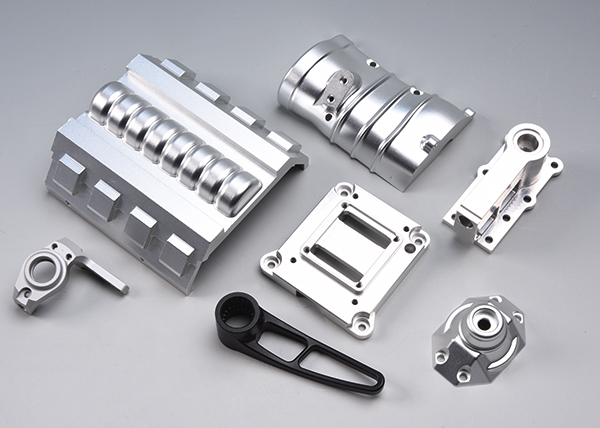

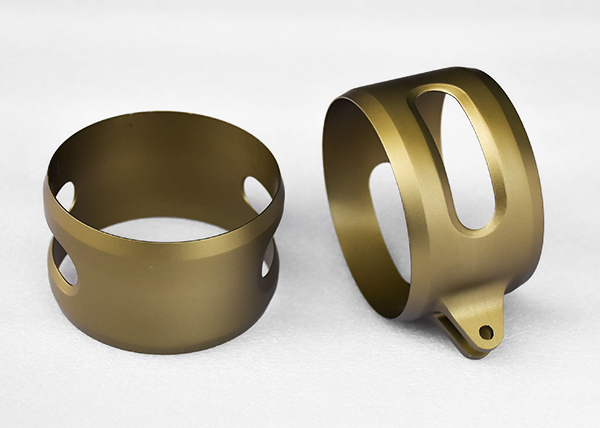

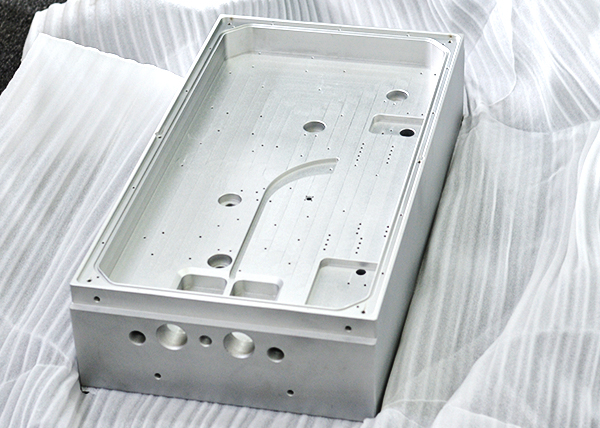

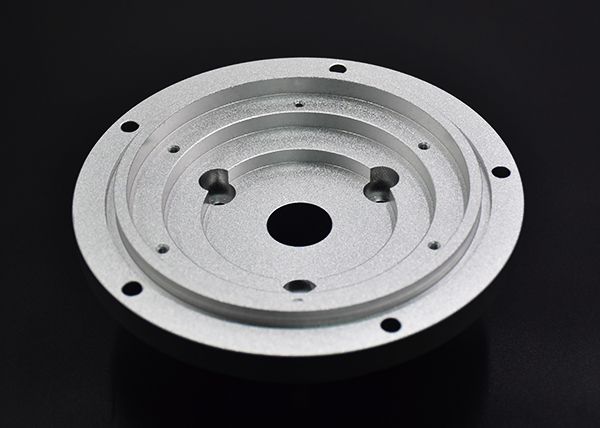

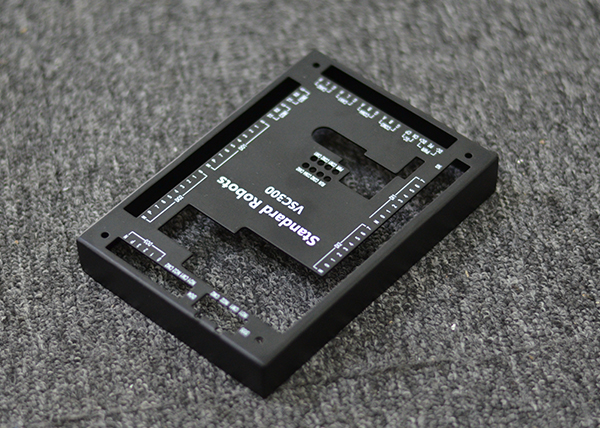

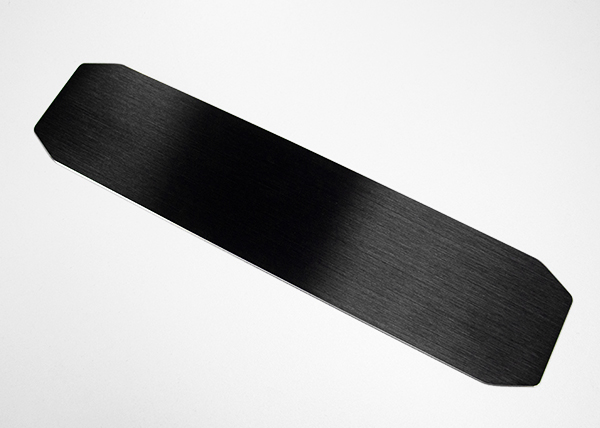

High precision CNC Milled Parts Produced By SogaWorks

We produce precision CNC milled prototypes and end-use parts for our valued customers.

CNC Milling Tolerance

If not otherwise specified on the technical drawing, all parts will be machined to ISO 2768 tolerance standards below. Generally, you can choose ISO 2768-m, ISO 2768-f or specify tighter tolerances in your 2D technical drawings.

Limits for nominal lengths |

ISO 2768-m |

ISO 2768-f |

|---|---|---|

|

0.5mm to 3mm |

±0.1mm |

±0.05mm |

|

Over 3mm to 6mm |

±0.1mm |

±0.05mm |

|

Over 6mm to 30mm |

±0.2mm |

±0.1mm |

|

Over 30mm to 120mm |

±0.3mm |

±0.15mm |

|

Over 120mm to 400mm |

±0.5mm |

±0.2mm |

|

Over 400mm to 1000mm |

±0.8mm |

±0.3mm |

|

Over 1000mm to 2000mm |

±1.2mm |

±0.5mm |

|

Over 2000mm to 4000mm |

±2.0mm |

- |

Limits for nominal lengths |

ISO 2768-m |

ISO 2768-f |

|---|---|---|

|

Up to 10mm |

±1° |

±1° |

|

Over 10mm to 50mm |

±0°30′ |

±0°30′ |

|

Over 50mm to 120mm |

±0°20′ |

±0°20′ |

|

Over 120mm to 400mm |

±0°10′ |

±0°10′ |

|

Over 400mm |

±0°05′ |

±0°05′ |

Limits for nominal lengths |

ISO 2768-m |

ISO 2768-f |

|---|---|---|

|

0.5mm to 3mm |

±0.2mm |

±0.2mm |

|

Over 3mm to 6mm |

±0.5mm |

±0.5mm |

|

Over 6mm |

±1.0mm |

±1.0mm |

Roughness and threads

CNC Milling Materials

CNC Milling Metals

SogaWorks provides 50+ metals and grades for your CNC milling parts selection, including aluminum 7075, 6061, stainless steel 304, 316, copper and more.

CNC Milling Plastics

SogaWorks provides 20+ metals and grades for your CNC milling parts selection, including ABS, POM, acrylic, PC and others.

CNC Milling Surface Finishes

Surface finishes are crucial for achieving the desired functional or aesthetic quality of CNC machined components. At SogaWorks, we offer a spectrum of surface finishes to enhance your parts’ function by improving hardness, roughness, corrosion and heat resistance.

Grow a thickness oxide layer ranging from 0.0001 to 0.001 inches to protect and color aluminum CNC machined parts for corrosion resistance and aesthetics.

Anodizing Type II

Create a thicker layer ranging from 0.001 to 0.004 inches. it is ideal for where hardness and wear resistance are crucial.

Anodizing Type III

Preserve or enhance the electrical conductivity of the aluminum parts while still providing the benefits of traditional type II.

Conductive Anodizing Type II

Cover a part with a thin layer of metal by electrochemical deposition for function, decoration or corrosion resistance.

Electroplating

Apply a protective coating of zinc to steel, iron, and copper objects to prevent corrosion.

Galvanizing

Apply a protective or functional coating to surfaces. It involves the application of liquid paint and then undergoes a curing process to solidify the paint film.

Painting

Apply a protective and decorative coating to materials, primarily metals. It involves applying a dry powder onto a surface, which is then applied electrostatically and cured under heat or UV light.

Powder Coating

Spray silica sand to the surface of the workpiece using compressed air to clean, smooth, or texture surfaces, providing a desired finish for functional or aesthetic purposes.

Sand Blasting

Apply images, patterns, or text to surfaces.

Silk Screen

A conversion coating applied to ferrous metals to provide a thin, protective layer of black iron oxide.

Black Oxide

Use abrasive belts or roller brushes to refine and improve the surface quality of components.

Brushing

Selectively remove material from the surface, resulting in a smooth, polished, and often corrosion-resistant finish.

Electropolishing

CNC Milling Design Guidelines

Review the recommended and practical guidelines for the most common features found in CNC milled parts.

Features |

Recommended |

Feasible |

|---|---|---|

|

Min. Feature |

Ø 2.5 mm |

Ø 0.5 mm |

|

Internal edges |

R 8mm |

R 0.25mm |

|

Mini. wall thickness |

0.8 mm (for metals) |

0.5 mm (for metals) |

|

Holes |

Diameter: standard |

Diameter: Ø 0.5 |

|

Threads |

Size: M6 or larger |

Size: M2 |

What is CNC Milling?

CNC milling is a subtractive process that uses rotating cutting tools to remove material to manufacture parts of complex shapes. The computer program controls the movement of the tools to achieve efficient and precision machining. CNC milling usually includes 3-axis, 4-axis and 5-axis machining. 5-axis CNC machines can produce parts with high geometric complexity without needing multiple machine setups. CNC milling can achieve tolerances up to ±0.005mm and is suitable for various materials such as metals, plastics and composites.

Serving Multiple Industries

Our rapid prototyping and on-demand production services are used across a wide range of industries, but the following areas are where we have the most experience.

Medical

Elevate the reliability of your medical devices with accurate manufacturing solution.

Aerospace

Lightweight and durable solutions for the most demanding aviation needs.

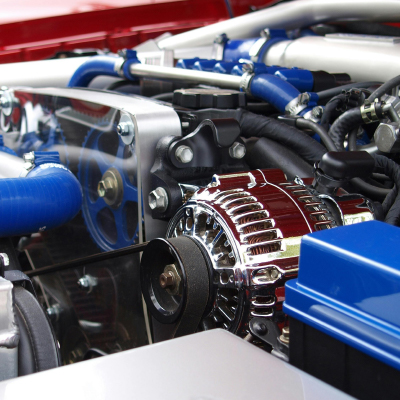

Automotive

Tailored to optimize performance and reliability in the automotive.

Robotics

Fuel your robotic innovations with our precision-engineered parts.