CNC Machining Service in China

Effortlessly outsource your custom CNC machined parts to reliable manufacturer in China.

- Tight tolerance up to ±0.005mm

- 3, 4, 5 axis CNC miliing for complex geometries

- A broad range of metals, plastics available

- Affordable, reliable solutions with fast turnaround

Start A CNC Machining Quote

STEP I STP I SLDPRT I PRT I IPT I DWG I PDF I DXF I ZIP I RAR

All drawings are secure and confidential.

Custom CNC Machining Service in China

Are you still looking for a reliable and fast-turnaround manufacturer in China for your CNC machined projects? SogaWorks is your go-to partner!

We have developed a highly vetted network of CNC machining manufacturers in China, enabling us to produce high-quality parts that meet a wide range of budget and lead time requirements. Production is handled by our trusted partners, with quality assurance managed by us. SogaWorks handles all communication with the Chinese supplier so you don’t have to.

At SogaWorks, our ISO 9001&14001 certified facility ensures top-notch quality control. Our unmatched team of machinists, engineers, and quality control experts work together throughout the entire process.

Our CNC machining services capacities include milling, turning, lathe, routing, grinding, and supporting over 50 high-performance metals, plastics, and composites, along with a wide range of surface finishing options.

What is CNC Machining?

Computer numerical control (CNC) machining is a process, which utilizes pre-programmed codes(G-codes) to control cutting tools to cut extra materials to shape metal &plastic blankpiecies into desired geometries.

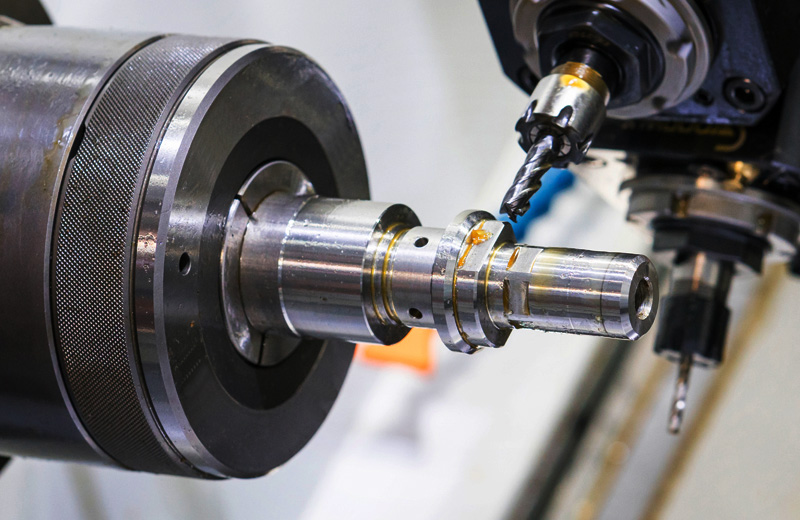

CNC Machines include multi-axis CNC machines, milling, lathes, and routers. CNC milling uses a rotating cutter to remove material and is suitable for flat and complex shapes. Lathes are used for creating precise cylindrical parts. CNC routers operate similarly to milling machines but are typically for softer materials like plastics.

Our China CNC Machining Service

CNC milling uses multi-axis operations, including 3, 4, and 5-axis machining, to create intricate geometries from metal or plastic blocks. This process produces parts with the tightest tolerance as tight as ±0.001 inches.

CNC turning shapes metal rod stock into cylindrical turned parts. This process ensures the parts maintain consistent dimensions and achieve smooth finishes, with the tightest tolerance of ±0.001 inches.

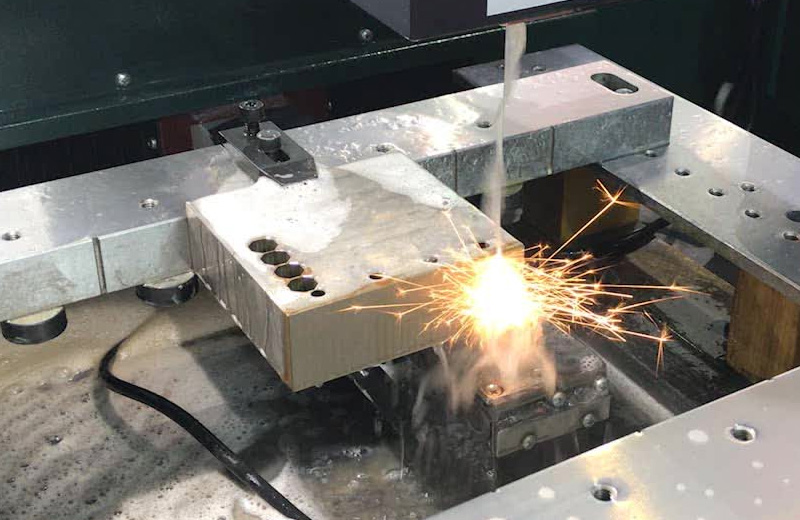

We offer additional CNC machining services, such as drilling, reaming, tapping, and wire cutting. These processes play a crucial role in ensuring that parts are produced with high precision and good functionality.

Advantages of China CNC Machining Service

# Expertise and Precision

Our trusted suppliers are equipped with advanced CNC machines, ensuring each parts adhere to tight tolerances, as tight as ±0.001 inches. Our dedicated team of engineers and QC experts will monitor the entire process.

# Fast Lead Time

With a self-developed automated platform, SogaWorks can quickly price you within 5 seconds. The system automatically matches you with the most suitable production capacity, simple-geometries parts in as fast as 1 day and 5 days for most parts.

# Certified Quality Assurance

Our manufacturing processes comply with key industry standards. Our facilities are ISO 9001:2015 certified for quality management, ISO 14001:2015 for environmental practices. We perform strict quality control standards to ensure the consistency of parts.

# On-demand Machining

Whether you need rapid prototyping or small-volume production, we offer a wide array of CNC processes, materials and surface finishing options. Our goal is to deliver cost-effective solutions tailored to your specific needs.

Work with China CNC Machining Manufacturer

Upload CAD Files

Uploading your design files, including 2D drawings or 3D models. Ensure that all necessary specifications and requirements are clearly configured, as this will help the manufacturer understand your needs.

Confirm Order

Once configured specs, you will get an automated quote. All you need to do is place your order. After confirming, the production process will begin, with our team will keep you updated on progress.

QC and Delivery

After production, our quality control team will thoroughly inspect the parts to ensure they meet the specified standards and tolerances. Once approved, your order will be packaged and shipped.

High-precision CNC Machined Parts

Based in China, SogaWorks delivers precision CNC machining services with a commitment to quality and accuracy. We follow ISO 2768-m standards or your 2D drawings to machine your parts, with the tightest tolerances of ±0.001 inches.

Our CNC machining capacities allow maximum dimensions of 4000*1500*600mm for milling and 200*500mm for turning, and lead times as fast as 3 days.

Whether you need rapid prototypes or large-scale production, we can handle them to meet your requirements.

As machined

Parts are left with visible tool marks and potentially sharp edges and burrs, which can be removed upon request. The surface finish is comparable to 125 Ra finish.

Anodizing

Anodizing offers enhanced corrosion and wear resistance with a decorative finish in custom colors. This process is ideal for aluminum prototypes.

Sand blasting

Sand blasting creates a smooth, matte surface by removing imperfections. It is usually used to prepare parts for further finishing processes such as anodizing.

Passivation

Passivation is a chemical process that uses acidic solutions to enhance the corrosion resistance of CNC machined stainless steel parts. Thickness is negligible, about 0.0000001″

Powder coating

Powder coating is where powdered paint is sprayed onto surface of parts, which is then cured under heat to form an even, protective layer.

Gold Plating

Gold plating applies a thin layer of gold to the surface of parts. This process aims to upgrade the tarnish and corrosion resistance. Thickness is about 0.00002″ – 0.00005″