Custom Metal Bending Service

Custom bending metal parts for rapid prototyping and large production runs. Free metal bending quote with DFM review within 1 day. Lead time as fast as 3 days!

Start A Metal Bending Quote

STEP I STP I SLDPRT I PRT I IPT I DWG I PDF I DXF I ZIP I RAR

All drawings are secure and confidential.

Metal Bending Workshop

Our Metal Bending Workshop is equipped with the latest CNC technology, combined with a team of highly qualified professionals, making us uniquely capable of supplying very precise and custom metal bending for several industries. We specialize in bending different materials, from stainless steel to aluminum and copper, and our experience in handling simple to complex designs is unparalleled.

In addition to bending, we offer a variety of other processes, such as laser cutting, and surface finishing, to ensure the parts are ready for immediate use right from the workshop.

Why Choose Our Metal Bending Service

Precision and Accuracy

Our advanced CNC technology ensures every metal bending operation is performed with accuracy. Every part is bent exactly to meet tight tolerances and complex geometries.

Wide Material Compatibility

We bend a wide variety of metals, including stainless steel, mild steel, aluminum, copper, and brass. The laser cutting service will take into consideration the different thicknesses and complex geometries to offer you versatility in your designs.

Fast Turnaround

Time is critical, and we prioritize fast lead times without compromising on quality. Our efficient workflow, advanced bending machines, and skilled team enable us to deliver metal-bent parts quickly.

Engineering Support

Our engineering team turns design challenges into viable solutions. We provide hands-on support to make sure your custom laser cutting projects receive the best technical advice and design optimization.

Metal Bending Capabilites and Tolreances

Description |

General Tolerance |

|---|---|

|

Maximum Part Size |

1.5m x 1.5m |

|

Sheet Thickness |

Up to 60mm |

|

Bend to edge/hole, single surface |

+/- 0.254mm (+/- 0.010 in.) |

|

Bend Radius |

At least 1X material thickness |

|

Bend Angle |

+/- 1° |

|

Lead Time |

5-7 business days |

Metal Bending Design Guidelines

It is essential to follow several design guidelines to ensure that your metal parts are optimized for both functionality and manufacturability.

- Bend Radii. The minimum bend radius can vary depending on the materials, you can view our metal bending guide to view the minimum bend radius reference chart. It is recommended a minimum bend radius equal to the thickness of the sheet.

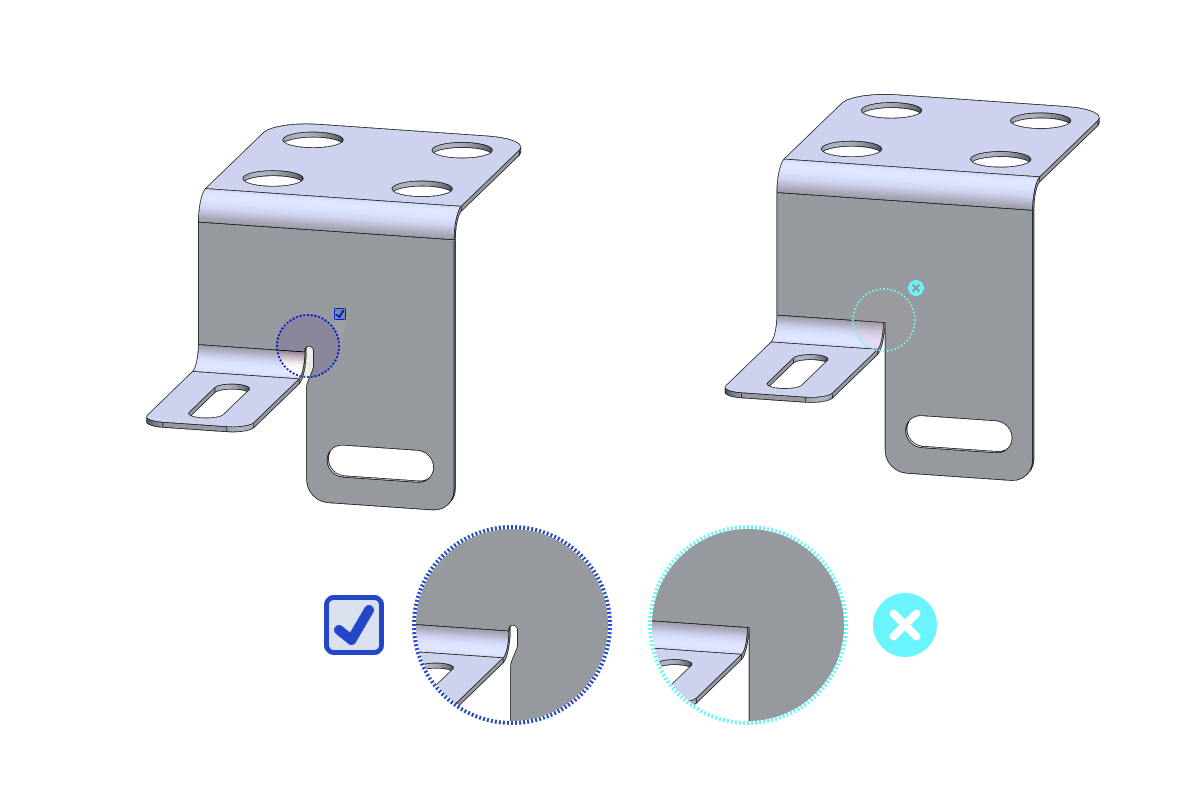

- Bend Relief. The length of the relief must be larger than the radius of the bend, and the width should be at least equal to the material’s thickness.

- Bend Height. The bending height should be at least twice the thickness of the sheet metal plus the bending radius.

Bendable Sheet Metals at SogaWorks

Materials |

Grades |

|---|---|

|

Aluminum |

Aluminum 5052, Aluminum 1060 |

|

Stainless steel |

Stainless steel 201, Stainless steel 304 |

|

Steel |

SPCC, Galvanized Steel (SGCC / SECC), Q235, 1045 |

|

Copper |

Copper C101, Copper C103, Copper C110 |

What is Metal Bending?

Bending is a type of metal deformation done in manufacturing for getting specified shapes or angles, basically performed with machines like the press brake that uses controlled force upon the metals for bending them at specific angles or curvatures. It is ideal for parts requiring precise, repeatable bends. Metal bending is able to ensure the strength and accuracy of the finished product by carefully controlling factors such as bend radius, angle, and material thickness.

Advantages of Metal Bending

- Precision and flexibility. Modern CNC bending technology ensures that each bend is made with exact accuracy, maintaining consistent dimensions and tolerances across all parts. This is so important for meeting the most demanding specifications.

- Strength and durability. Bending is a process that does not compromise the material‘s strength; therefore, the final product is structurally strong, with resistance to wear and tear over time.

- Cost-effective. Metal bending, particularly with high-volume production, would negate the need for further processes like welding or assembly, which has to do with bringing down general production costs.

Serving Multiple Industries

Our rapid prototyping and on-demand production services are used across a wide range of industries, but the following areas are where we have the most experience.

Medical

Elevate the reliability of your medical devices with accurate manufacturing solution.

Aerospace

Lightweight and durable solutions for the most demanding aviation needs.

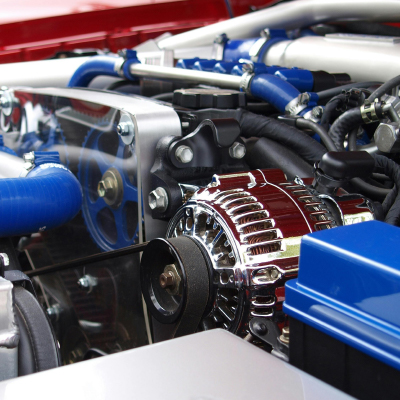

Automotive

Tailored to optimize performance and reliability in the automotive.

Robotics

Fuel your robotic innovations with our precision-engineered parts.