Aluminum in CNC Machining

Explore aluminum CNC machining with our selection of alloys and grades. From 6061 to 7075, aluminum offers versatility, combining lightweight construction with exceptional strength and durability.

All drawings are secure and confidential.

Available Alloys And Grades

Aluminum 2024

Aluminum 7075-T6, an aerospace-grade material, exhibits an outstanding strength-to-weight ratio, high strength and hardness.

- Tensile strength: 425 MPa

- Yield strength: 275 MPa

- Elongation at break: 14%

- Hardness: 120 HB

Aluminum 5052

Aluminum 5052, favored for its corrosion resistance, finds widespread use in marine and architectural industries.

- Tensile strength: 215 MPa

- Yield strength: 65 MPa

- Elongation at break: 12%

- Hardness: 45 HB

Aluminum 6061

Aluminum 6061, the most popular aluminum alloy , offers a balance of strength, weldability, and natural corrosion resistance.

- Tensile strength: 290 MPa

- Yield strength: 240 MPa

- Elongation at break: 9%

- Hardness: 95 HB

Aluminum 6063

Aluminum 6063 has good mechanical properties and can be heat treated. It is commonly utilized in structural applications

- Tensile strength: 205 MPa

- Yield strength: 170 MPa

- Elongation at break: 9%

- Hardness: 75 HB

Aluminum 7075

Aluminum 7075-T6, an aerospace-grade material, exhibits an outstanding strength-to-weight ratio, high strength and hardness.

- Tensile strength: 540 MPa

- Yield strength: 475 MPa

- Elongation at break: 8%

- Hardness: 150 HB

Aluminum MIC-6

Aluminum MIC-6, being lightweight, facilitates high-speed machining while remaining free from tension, contaminants, and porosity.

- Tensile strength: 116 MPa

- Yield strength: 105 MPa

- Elongation at break: 5%

- Hardness: 65 HB

* Generalized values. For reference only.

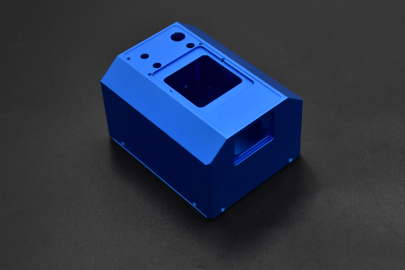

Finishes And Post-Processing Options

SogaWorks provides an extensive selection of surface finishes tailored for aluminum alloys, Anodization stands out as the most favored process, offering both normal and hard-coating options. These treatments significantly enhance wear and corrosion resistance across our aluminum alloy spectrum.

Anodizing

Chrome plating

Galvanizing

Nickel plating

Painting

Powder coating

Sand blasting

Silk screen

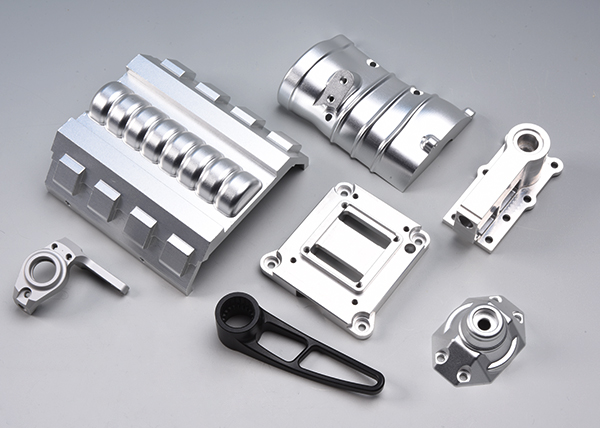

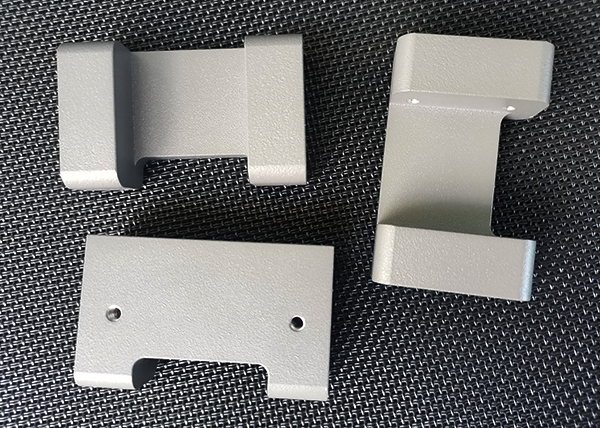

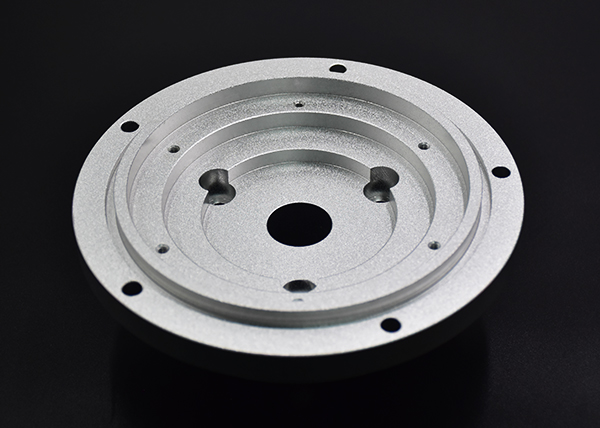

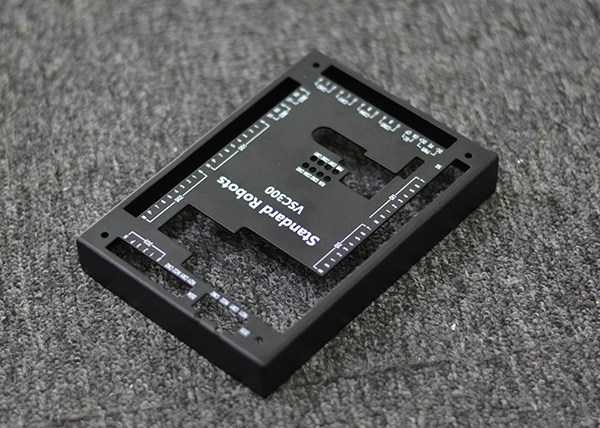

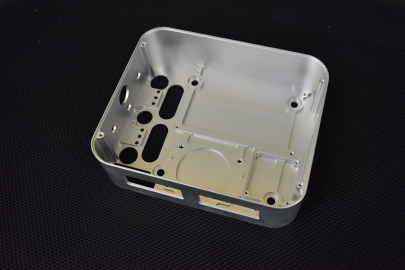

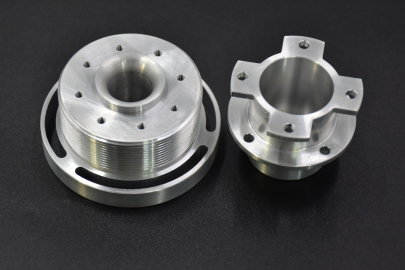

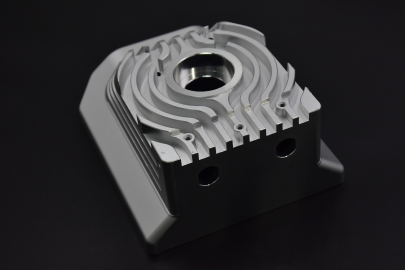

Gallery of CNC machined Aluminum Parts

FAQs Aout Aluminum CNC Machining

The most common aluminum alloys used for CNC machining include 6061, 7075, 2024, and 6063. Each alloy offers unique properties suitable for different applications and machining requirements.

The cost of CNC machining aluminum alloys depends on factors such as the type of alloy used, part complexity, tolerances required, surface finishes, batch size, and machining time. We offer competitive pricing tailored to your project needs.

Yes, aluminum alloys can be CNC machined to tight tolerances, often within ±0.005 inches or better, depending on the machining equipment, tooling, and part geometry.

Aluminum alloys can be finished with various surface treatments including anodizing, powder coating, painting, bead blasting, and polishing, to enhance aesthetics, corrosion resistance, and wear properties.