Online Custom Injection Molding Service

We specialize in delivering injection molding services from plastic molded prototypes to massive custom production.

- Free DFM report

- MOQ ≥ 500 PCS

- 100% full inspection before delivery

Start Injection Molding Quote

STEP I STP I SLDPRT I PRT I IPT I DWG I PDF I DXF I ZIP I RAR

All drawings are secure and confidential.

Injection Molding Process

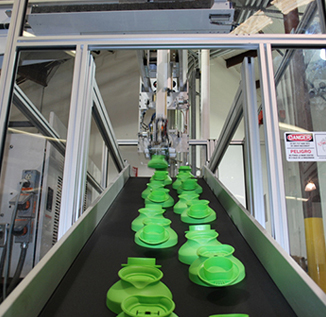

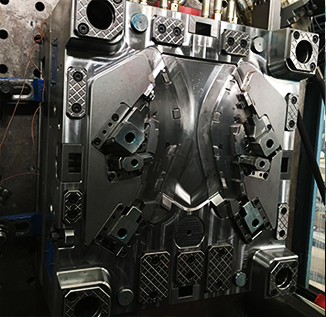

We are committed to delivering custom injection molding solutions for our customers, covering a spectrum of services such as plastic injection molding, insert molding, and overmolding. Utilizing innovative processes and state-of-the-art equipment, we are capable of producing molded components that meet your rigorous standards within remarkably short lead times.

Plastic Injection Molding

Plastic injection molding involves injecting molten thermoplastic into a mold, where it cools and solidifies into parts.

Overmolding

Overmolding combines two or more materials by molding one plastic material over another, creating an integrated part.

Insert Molding

Molding a metal or plastic component into a thermoplastic material to create a single, integrated part.

Bi-color Injection Molding

Allowing the production of plastic parts with two different colors or materials in a single molding cycle.

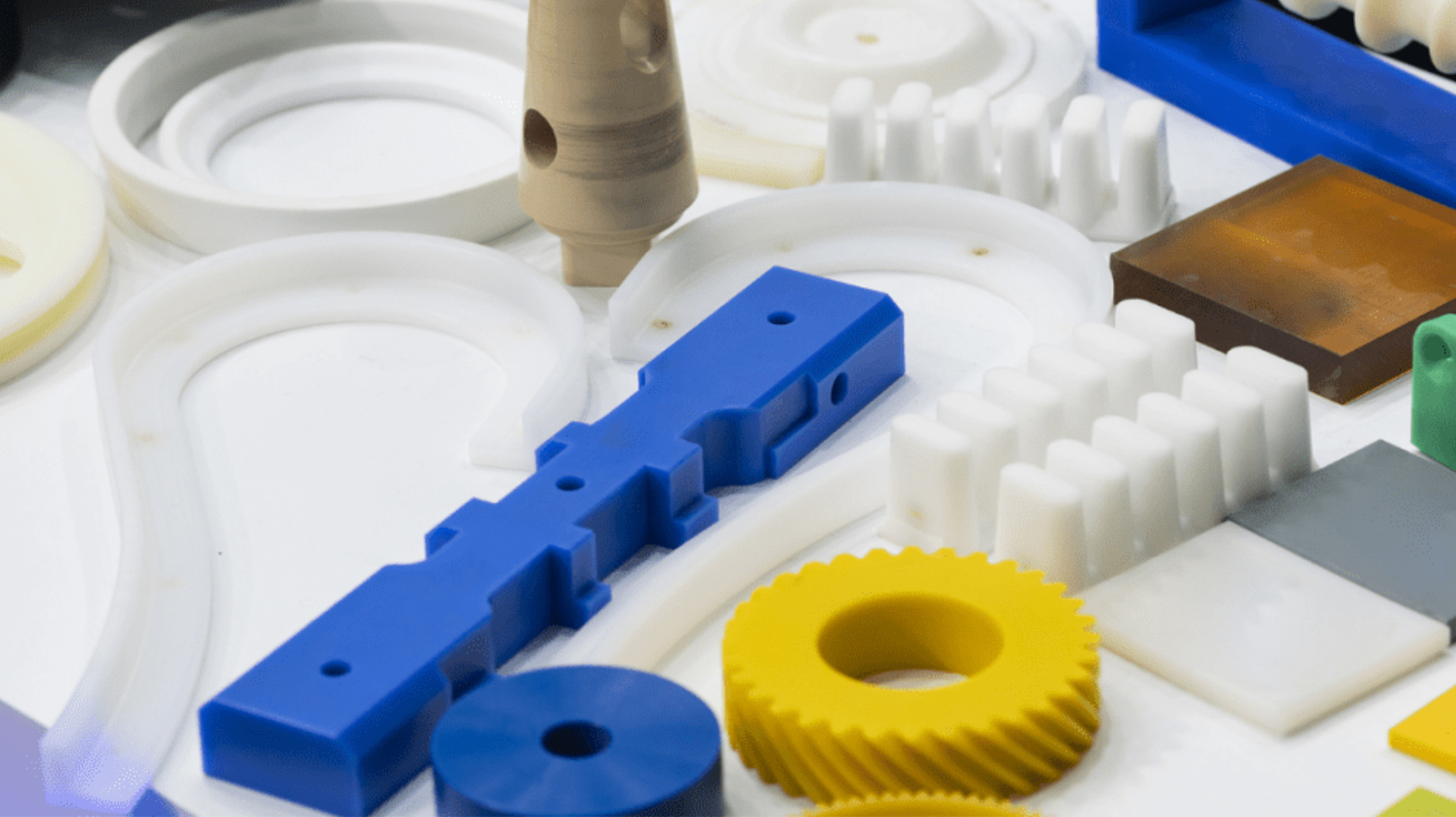

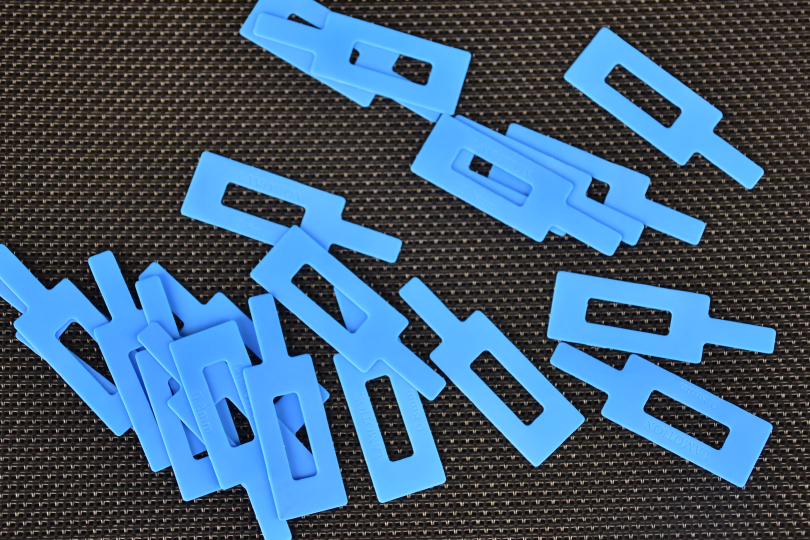

Injection Molded Parts Produced By SogaWorks

Gallery of injection molding prototypes and end-use parts we have produced for our valued customers.

Injection Molding Tolerance

- For non-critical applications, such as for some consumer products, the tolerance for injection molded parts is typically ±0.1mm. For applications that require tighter tolerances, such as injection molded medical parts, ±0.025mm is typical.

- The molds will be CNC machined to standard tolerances of ±0.125mm (±0.005") after adjusting for part shrinkage. Tighter tolerances can be requested and may increase the cost of tooling.

- Part-to-part repeatability is typically under 0.100mm(0.004").

- Unless otherwise specified, all quotes are based on the assumption that standard injection molding equipment will be used. If special tooling configurations are required, they must be expressed during the quoting process.

Injection Molding Materials

SogaWorks offers an extensive range of plastic materials for your injection molding projects, which brings you multiple material options to complete prototypes and production runs of custom parts.

Thermoplastics

Polymer that can be melted and re-molded multiple times without undergoing significant chemical change.

- ABS

- ABS/PC

- HDPE

- LDPE

- PA(Nylon)

- PBT

- PC

- PC/PBT

- PEEK

- PEI

- PET

- PETG

- PP

- PPS

- PS

- PMMA (Acrylic)

- POM (Acetal/Delrin)

Surface Finishes

We offer a variety of high-level surface finishes and only some common finishing options are listed as below. There are more finish options for custom injection molding parts.

Applying a protective or functional coating to surfaces. It involves the application of liquid paint and then undergoes a curing process to solidify the paint film.

Painting

Applying images, patterns, or text to surfaces.

Silk Screen

Labeling, engraving, or adding information to materials. It involves using a laser beam to alter the surface of the workpiece, creating visible marks without physical contact.

Laser Marking

Manufacturing Capabilities and Equipment

- 30+ countries and regions

- 50,000+ customers

- 16,000,000+ parts manufactured in total

- 1,000+ collaborative partner factories

- 4,800+ precision equipment

What Our Customers Say

It was an amazing experience to work with SogaWorks people. They are very professional and caring and keep up smooth communication over our outsourced parts production. We will continue to partner with their service for future projects.

We have lots of projects for small quantity parts. SogaWorks has always treated our requests fairly. What is more, they provided us with valuable technical feedback. We really appreciate their genuine desire to help.

Postdoctoral Scholar, Stanford University

SogaWorks demonstrates professionalism. They enabled our purchasing process at ease. We don't have to juggle around managing various suppliers. You save the day. Great job!

Purchasing Specialist, Panasonic China

We would like to express our thanks for your down-to-earth support on our rush orders. Our requirements were rigid and the delivery deadlines were tight. Yet, all orders have been delivered perfectly. This is a team that can take challenging jobs.

Project Manager, HP

Our Advantages

Fast Turnaround

We reduce your product development cycle and bridge to production with injection-molded parts as fast as 2 weeks, even less.

One-stop Service

We provide injection molding services from R&D prototypes to large-volume production, covering extensive materials and multiple surface finishes. Get your parts delivered right to your door without the hassle of project management, logistics, or shipping.

Design Optimization

Once we get your request for injection molding, our experts in mold tooling and injection molding will take a close look at your molded parts and Provide DFM feedback within 24 hours.

Strong Network

We are ISO9001:2015, ISO 14001 certified. We have built up a strong and efficient network of qualified shops, only top-notch shops that apply to become our suppliers can pass the qualification process.

Serving Multiple Industries

Our rapid prototyping and on-demand production services are used across a wide range of industries, but the following areas are where we have the most experience.

Medical

Elevate the reliability of your medical devices with accurate manufacturing solution.

Aerospace

Lightweight and durable solutions for the most demanding aviation needs.

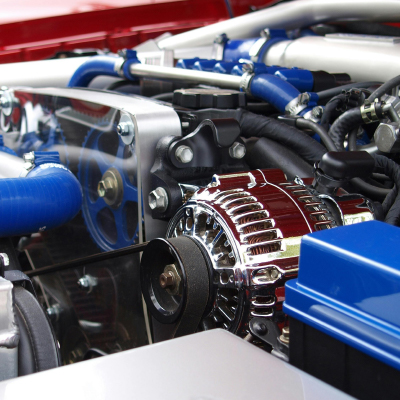

Automotive

Tailored to optimize performance and reliability in the automotive.

Robotics

Fuel your robotic innovations with our precision-engineered parts.

FAQs About Injection Molding Service

What is the minimum order qty of injection molding service?

We have a minimum order qty of 500 pcs. For orders below this quantity, we recommend considering 3D printing or vacuum casting, as these methods are often more cost-effective while still meeting your tolerance requirements.

How long does it take to the injection molding service?

Once an order is placed, the process begins with mold design and creation, which typically takes around 3-5 days. After the mold is ready, it usually takes an additional 3-5 days to produce the molded parts. This timeline ensures that each step, from designing to final production, is handled with precision and attention to detail, guaranteeing high-quality results for your project.

How much does the service cost?

The cost of our services is influenced by various factors, including the size of the components, the complexity of the mold, the number of cavities, the type of material used, and any post-processing requirements. To ensure accurate pricing, we analyze these factors in detail on our platform before providing a quote. This comprehensive evaluation allows us to offer competitive and tailored pricing for each project, ensuring that you receive the best value for your investment.