Custom CNC Machining Service

Get instant quotes on your custom metal or plastic parts with SogaWorks’ online CNC machining services, choosing from 40+ advanced materials and 20+ surface finishes.

-

Rapid prototyping and production

-

Quote in 5s with intelligent quotation system

-

MOQ 1 PC and as fast as 2 days delivery

-

Fully inspected before delivery

Start A New CNC Quote

STEP I STP I SLDPRT I PRT I IPT I DWG I PDF I DXF I ZIP I RAR

All drawings are secure and confidential.

Robust CNC Machining Capabilities

SogaWorks offers industry-leading online CNC machining services. Whether you need machined prototypes or low-volume production parts, simple or complex geometries, aesthetic or functional parts, our robust CNC machining capabilities can produce them for you as fast as 1 day.

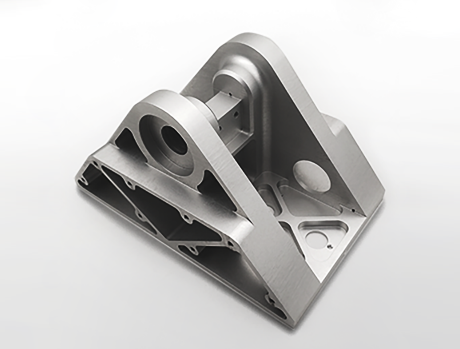

3, 4, 5-aixs CNC Milling

For producing high-precision parts with simple or the most complex geometries, we have numerous sets of advanced multi-axis CNC machines, like 3-axis, 4-axis, and 5-axis CNC milling centers.

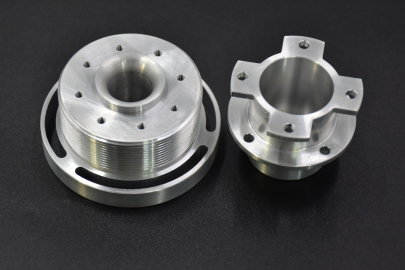

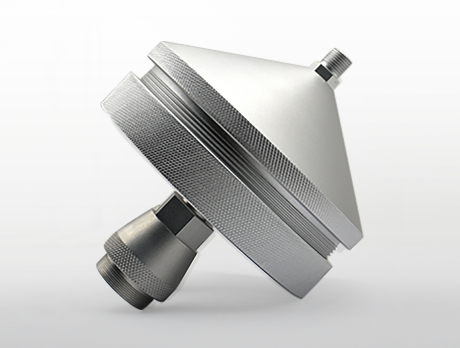

CNC Turning

With a wide range of CNC lathes and CNC turning centers, we can create highly accurate, symmetrical cylindrical, or spherical parts in line with your stringent requirements.

Surface Finishing

Choose from over 20 finishing options for CNC machined parts that eliminate surface defects, enhance cosmetic appearance and appeal, and provide greater durability.

Why Choosing Us to Source Your Custom Parts

Quote in 5 Seconds

Utilizing a self-developed, machine learning-driven intelligent quoting system, we can offer rapid quotations for your inquiry in 5 seconds.

One-Stop Manufacturing Service

We provide one-stop manufacturing services from R&D prototypes to massive production, covering hundreds of materials and most of the surface finishes.

End-to-end Professional Service

Our specialized account managers and engineers provide “One to One” service, and work collaboratively with both customers and partners by better understanding their requirements, which is to achieve better turnaround time and lower cost for your project.

Fully Inspected Before Delivery

Before shipping out the parts to you, we conduct a strict final inspection for all parts with high-accuracy measuring equipment.

Advanced Facilities Ensure High Quality Parts

We guarantee the quality and consistency of CNC machined parts are maintained or improved. Our in-house quality control team operates strict visual and dimensional inspections to make sure the parts are free from defects and meet your requirements.

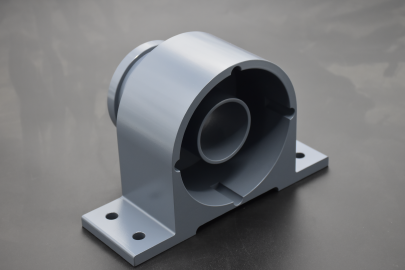

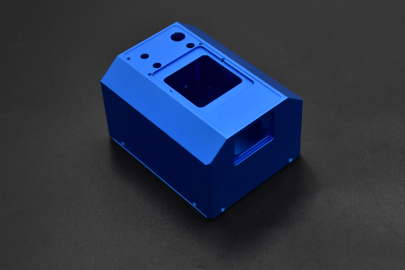

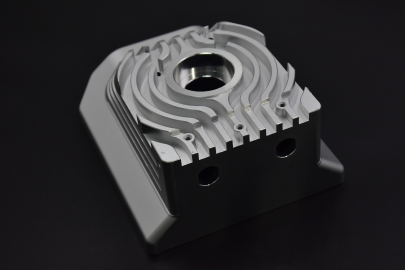

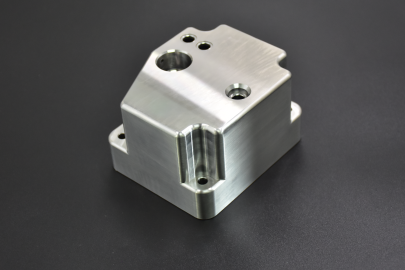

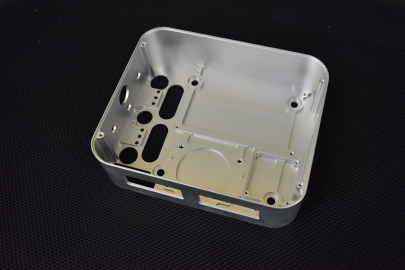

Gallery of CNC Machined Parts

Check out our extensive gallery that shows precision machined prototypes and end-use parts from our valued customers.

From Rapid Prototypes to High-volume Production

Rapid Prototyping

We can produce your prototypes in days, allowing you to quickly validate product designs.

Low-Volume Machining

we offer multiple cost-efficient solutions to make certain types of parts from small to medium volume.

On-demand Production

Experience flexibility for orders of any size with our on-demand production service.

CNC Machining Materials

Many materials can be used in CNC machining technologies, which bring you a wide range of options for your CNC machined parts. At Sogaworks, we provide instant quotations on 40+ industrial-grade metal and plastic materials.

CNC Machining Metals

Aluminum

Excellent toughness and wear resistance, it is an all-round material and has been widely used in industry.

Available alloys: 2024, 5052, 6061, 6063, 7075, MIC-6

Stainless steel

High strength and durability, corrosion resistance, temperature resistance.

Available alloys: SUS 303, 304, 304L, 316, 316L, 17-4PH and more.

Steel

Ductility and formability, high strength and toughness, fatigue resistance.

Available alloys: 1045, 1215, 4130, 4140, 4340, 5140

Copper

Superior Electrical Conductivity, thermal conductivity, corrosion resistance.

Available alloys: C110, C102, C101

Brass

Excellent machinability, aesthetic appearance, corrosion resistance.

Available alloys: C2800, C2801, C260, C360

Titanium

Excellent strength-to-weight ratio, corrosion resistance, biocompatibility.

Available alloys: 6Al-4V

CNC Machining Plastics

ABS

ABS is a commonly used thermoplastic polymer with excellent impact, temperature and chemical resistance. It is also easy to machine and process and has a smooth surface finish.

HDPE

HDPE has high strength-to-density ratio, which gives it excellent strength while remaining lightweight. It also has excellent resistance to most solvents and is very resistant to many different kinds of chemicals.

LDPE

LDPE is less rigid and generally less chemically resistant than HDPE, but it is more translucent. It is very flexible and is used in applications where heat sealing is necessary.

Nylon

Nylon is a generic designation for a family of synthetic polymers, based on aliphatic or semi-aromatic polyamides. It is known for its high strength, excellent resilience, and good resistance to wear and abrasion.

PC

PC (polycarbonate) is a type of amorphous thermoplastic known for its high impact resistance and transparency. It also demonstrates good electrical insulation properties and moderate chemical resistance.

PEEK

PEEK is a high-temperature resin used in safety-critical industries such as medical, aerospace and automotive. The high-performance material offers good chemical and heat resistance, as well as flame retardancy, and provides excellent strength and dimensional stability.

PMMA

PMMA, or acrylic, is a transparent thermoplastic. One of the most widely used plastics in the world, PMMA demonstrates good chemical stability, mechanical properties and weather resistance.

PTFE

PTFE (Polytetrafluoroethylene) has exceptional chemical resistance, heat resistance, low coefficient of friction and low coefficient of friction.

POM

POM (Polyoxymethylene) is an engineering thermoplastic material that demonstrates excellent dimensional stability, stiffness and impact and temperature resistance.

PP

Polypropylene (PP) is an inexpensive thermoplastic with variable impact resistance depending on the grade. PP is wear-resistant, flexible and can have high elongation, while it also has high chemical resistance.

PC

Polyurethane(PU) is a unique material that offers the elasticity of rubber combined with the toughness and durability of metal

PVC

PVC has high hardness and good electrical insulation and is resistant to weathering, chemical rotting, corrosion, shock, and abrasion.

CNC Machining Surface Finishes

Surface finishes are crucial for achieving the desired functional or aesthetic qualities of CNC machined components. we offer a spectrum of surface finishes that enhance the aesthetics and functionality of your custom projects.

As Machined

The fastest turnaround for finish options. Machined parts will have visible tool marks and may include sharp edges and burrs, which can be removed if requested. the finish gives parts a surface roughness of 3.2 μm.

Anodizing Type II

Anodizing Type II grows a thickness oxide layer ranging from 0.0001 to 0.001 inches to protect and color aluminum CNC machined parts for corrosion resistance.

Anodizing Type III

Anodizing Type III creates a thicker layer, which ranges from 0.001 to 0.004 inches.

Chrome Plating

Chrome Plating involves electroplating a thin layer of chromium onto a metal substrate to offer improved corrosion resistance, wear resistance, and aesthetic appearance.

Nickel Plating

A thin layer of nickel is deposited onto the surface of a metal object through electroplating, providing functional and aesthetic benefits.

Painting

Painting is a common method used for applying a protective or functional coating to surfaces.

Powder Coating

Powder coating is a process used to apply a protective and decorative coating to materials, primarily metals. It involves applying a dry powder onto a surface, which is then applied electrostatically and cured under heat or UV light.

Sand Blasting

Sandblasting is a process that involves spraying silica sand to the surface of the workpiece using compressed air. This technique is used to clean, smooth, or texture surfaces, providing a desired finish for functional or aesthetic purposes.

Black Oxide

A conversion coating applied to ferrous metals to provide a thin, protective layer of black iron oxide.

Electropolishing

Electropolishing is an electrochemical technique that selectively removes material from the surface, resulting in a smooth, polished, and often corrosion-resistant finish.

Silk Screen

Silk Screen is a printing technique used in CNC machining to apply images, patterns, or text to surfaces.

Laser Marking

Laser marking is a method to label, engrave, or add information to materials. It involves using a laser beam to alter the surface of the workpiece, creating visible marks without physical contact.