Titanium in CNC Machining

Titanium alloys feature a high strength-to-weight ratio and corrosion resistance, we offer titanium CNC machining service and can produce custom titanium parts in Titanium 6Al-4v.

All drawings are secure and confidential.

Available Alloys And Grades

Titanium 6Al-4V

Most commonly used titanium alloy that offers high strength, light weight, formability and corrosion resistance.

- Tensile strength: 895 MPa

- Yield strength: 825 MPa

- Elongation at break: 10%

- Hardness: 300 HB

* Generalized values. For reference only.

Finishes And Post-Processing Options

We offer a wide array of surface finish options for your selection, each option has its distinguished functions, such as enhancing function, corrosion resistance, and aesthetic appearance. You can choose the better options depending on your project’s requirements.

Anodizing

Chrome plating

Galvanizing

Nickel plating

Painting

Powder coating

Sand blasting

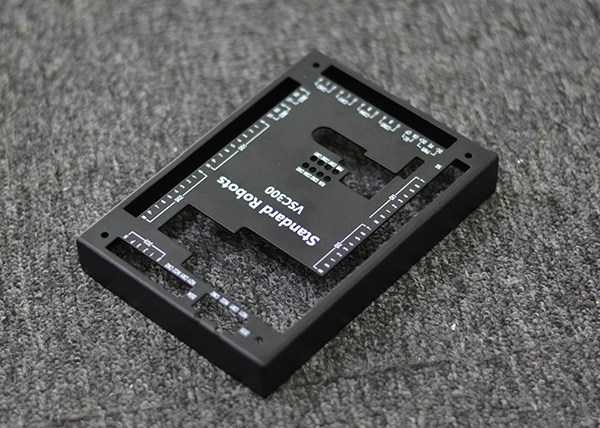

Silk screen

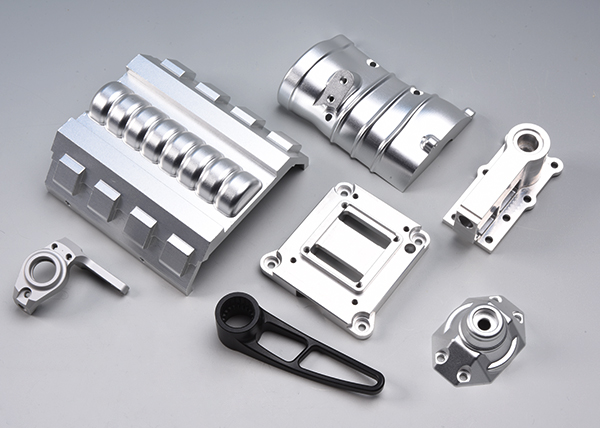

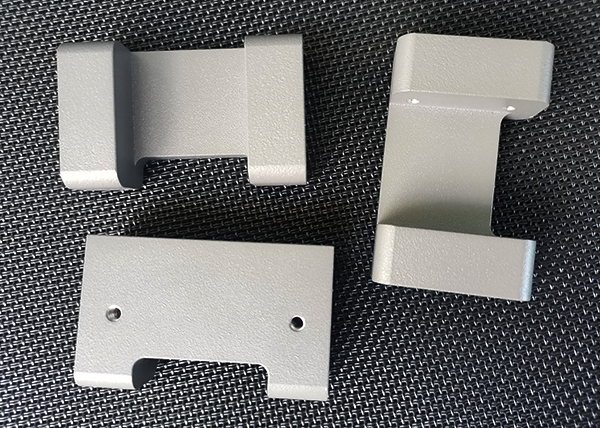

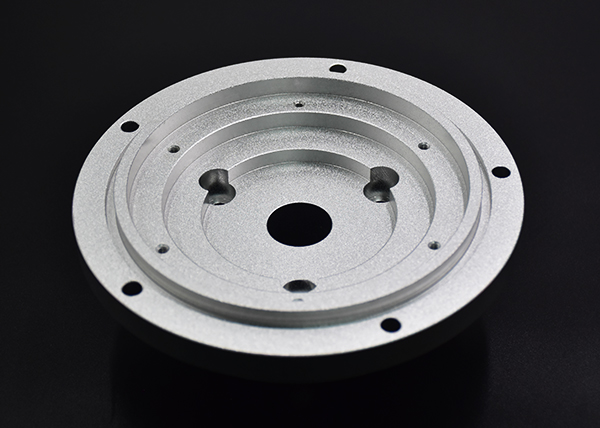

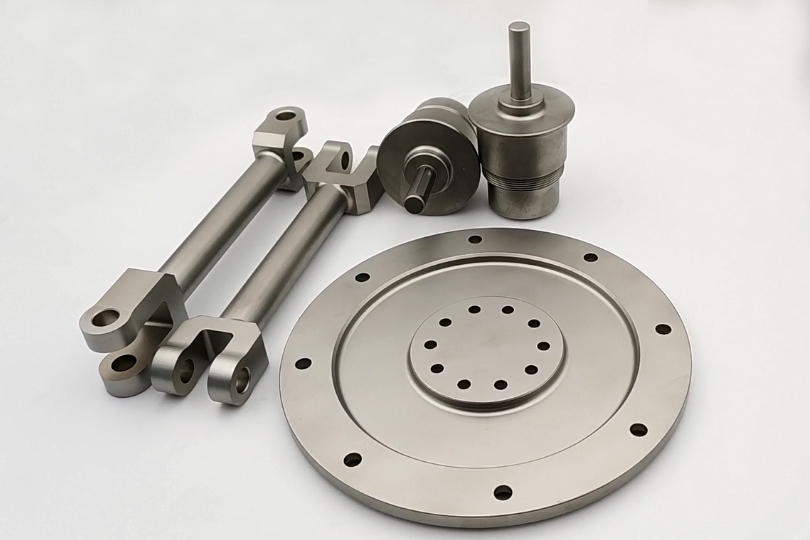

Gallery of CNC machined Titanium Parts

FAQs Aout Titanium CNC Machining

Titanium exhibits high strength while maintaining an impressive strength-to-weight ratio. Despite being slightly less strong than steel by just 5%, it boasts a significant weight reduction of 40%, making it a highly desired material in high-tech industries like aerospace, automotive, and energy.

Titanium alloy has good properties such as high specific strength, corrosion resistance, high temperature resistance, fatigue resistance, etc., making it one of the main structural materials of contemporary aircraft and engines, and is widely used in aircraft structural parts and heat-resistant parts. However, titanium alloys also have some shortcomings, such as low thermal conductivity, severe work hardening, high affinity with cutting tools, and small plastic deformation. These properties make titanium alloys extremely difficult to machine. Among them, the cutting performance of titanium alloy is only equivalent to 20% of that of free-cutting steel.

The cost of CNC machining titanium is generally higher compared to machining other common materials such as aluminum or steel. Several factors contribute to this disparity, such as material cost, specialized tools and equipment, machining Speed. Titanium alloy materials are recognized as one of the most difficult materials to process in the machining industry. The thermal conductivity of titanium alloy is low. When processing titanium alloy, the cutting speed of the tool is very slow and the processing time is long. This is an important reason for its high price.