Ferrous metals, characterized by their iron content, exhibit specific properties and applications that differ from those of non-ferrous metals, which do not contain iron. A comprehensive understanding of the variances between ferrous and non-ferrous metals is vital for professionals working in industries like construction, manufacturing, and engineering. This knowledge is crucial for informed decision-making and optimal material selection based on specific project requirements.

What are Ferrous metals?

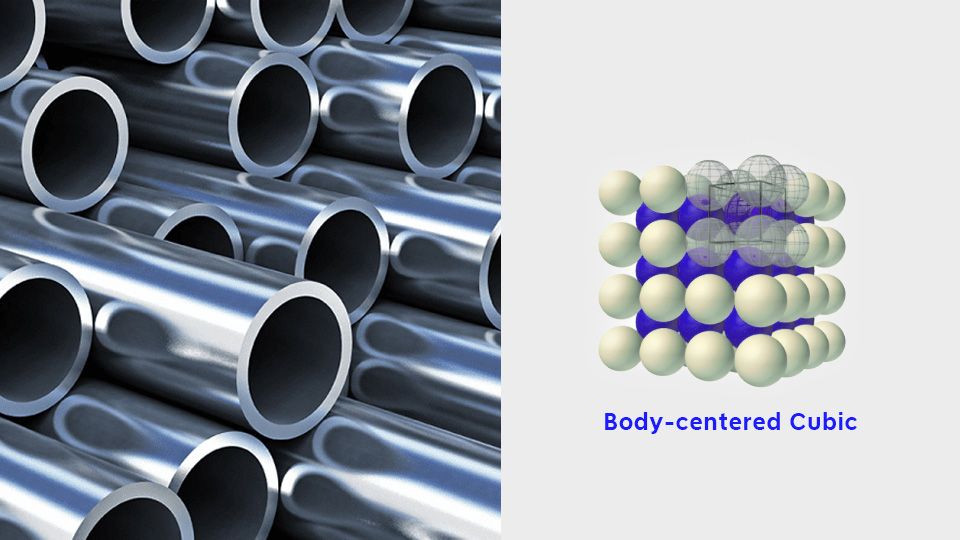

Ferrous metals are metals that contain iron as their primary constituent. The term “ferrous” is derived from the Latin word “ferrum,” which means iron. These metals are characterized by their iron content and often include various alloys that have iron as a major component, making them with their properties of magnetic, strong, and hard.

Ferrous metals include:

Carbon Steel: Carbon steel is one of the most widely used ferrous metals, comprising over 90% iron. Beyond its applications in construction and furniture, it finds extensive use in crafting automotive parts.

Cast Iron: With a higher carbon content compared to many other ferrous metals, cast iron is cost-effective and devoid of alloying elements other than iron and carbon. Its versatility is evident in its use for crafting wear-resistant cookware, gears, rods, pins, and mining equipment.

Wrought Iron: Distinguished from cast iron by its lower carbon content, wrought iron exhibits remarkable characteristics such as high elasticity, tensile strength, softness, ductility, and magnetism. It possesses the unique ability to be heated, reheated, and cast into diverse shapes. Notably, wrought iron stands out for its resistance to corrosion and oxidation, making it a preferred material for crafting nuts, bolts, handrails, outdoor stairs, fences, and gates.

Stainless Steel: Featuring a high chromium content, the chromium infusion enhances its durability and makes it well-suited for diverse applications. It finds application in various industries, including the manufacturing of appliances, pharmaceuticals, medical equipment, food-grade equipment, and knives.

Ferrous metals find diverse applications across various industries due to their strength, durability, and other unique properties. Here are some common applications of ferrous metals:

Construction: Structural elements such as beams, columns, and frameworks in buildings and bridges are often made from ferrous metals like steel for their strength and load-bearing capabilities.

Automotive Industry: Ferrous metals, particularly steel, are extensively used in the automotive sector for manufacturing components such as engine parts, chassis, and body structures due to their durability and impact resistance.

Machinery and Equipment Manufacturing: Ferrous metals play a vital role in the manufacturing of heavy machinery, equipment, and tools where strength, toughness, and wear resistance are essential.

Infrastructure: Ferrous metals, especially steel, are employed in the construction of infrastructure elements like pipelines, rail tracks, and utility structures for their durability and resistance to environmental stresses.

Shipbuilding: Steel, a ferrous metal, is a preferred material in shipbuilding due to its strength, weldability, and corrosion resistance in marine environments.

What are Non-ferrous Metals?

Non-ferrous metals are a category of metallic elements and alloys that do not contain iron as their primary component; instead, they encompass a diverse range including aluminum, copper, zinc, lead, tin, nickel, brass, bronze, titanium, and magnesium, valued for their properties such as corrosion resistance, electrical conductivity, malleability, and lightweight nature.

Non-ferrous metals include but are not limited to the following:

Aluminum: Aluminum is a lightweight and corrosion-resistant non-ferrous metal, that is extensively used in various industries, including aerospace, automotive, and packaging, owing to its excellent strength-to-weight ratio and versatility.

Copper: Renowned for its exceptional electrical conductivity and malleability, copper is a crucial non-ferrous metal employed in electrical wiring, plumbing, electronics, and architectural applications.

Bronze: Bronze, an alloy of copper and tin (sometimes with additional elements), is corrosion-resistant and durable, finding applications in sculpture, bearings, coins, and marine environments.

Titanium: Titanium, a lightweight and corrosion-resistant non-ferrous metal, is utilized in aerospace, medical implants, sporting goods, and chemical processing due to its high strength-to-weight ratio.

Non-ferrous metals find diverse applications across various industries, leveraging their unique properties. Here are specific applications for non-ferrous metals:

Electronics: Copper and aluminum, both excellent conductors of electricity, are widely used in electrical wiring, circuits, and electronic components.

Aerospace Industry: Aluminum and titanium, known for their lightweight properties, are extensively used in the aerospace sector for aircraft components, contributing to fuel efficiency.

Automotive Industry: Non-ferrous metals like aluminum and magnesium are utilized in the automotive sector to reduce the weight of vehicles, improving fuel efficiency.

Marine Industry: Copper-based alloys, such as bronze, are employed in marine environments for components like propellers and ship fittings due to their corrosion resistance.

Medical: Titanium, a corrosion-resistant non-ferrous metal, is used in the medical industry for implants and devices due to its biocompatibility and strength.

Power Transmission: Aluminum is commonly used in power lines and transmission cables because of its high electrical conductivity and lightweight nature.

Difference Between Ferrous and Non-ferrous Metals

The fundamental difference is that ferrous metals contain iron, and non-ferrous metals do not. The more in-depth answer is that ferrous and non-ferrous metals each have distinctive properties, making them suitable for different applications.

Magnetic Properties

Ferrous metals possess magnetic characteristics, exhibiting ferromagnetism and being attracted to magnets, while non-ferrous metals lack magnetic properties and are not drawn to magnets.

Corrosion Susceptibility

Ferrous metals are more prone to rust and corrosion in the presence of moisture and oxygen, primarily due to their iron content, whereas non-ferrous metals generally display greater resistance to rust and corrosion, making them valuable in applications where exposure to moisture is a concern.

Strength and Durability

Known for their robust strength and durability, ferrous metals are well-suited for structural and load-bearing applications. On the other hand, many non-ferrous metals, such as copper and aluminum, excel in conducting electricity and heat.