We offer multiple types of plastics for 3D printing technologies of SLS, SLA, FDM. From resins to red wax, custom materials are available for your 3D printed parts.

All drawings are secure and confidential.

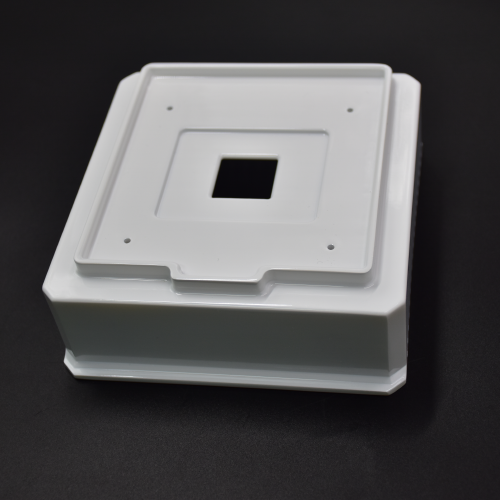

Photosensitive resin

High resolution, high strength, stiffness, and impact resistance.

$

More details

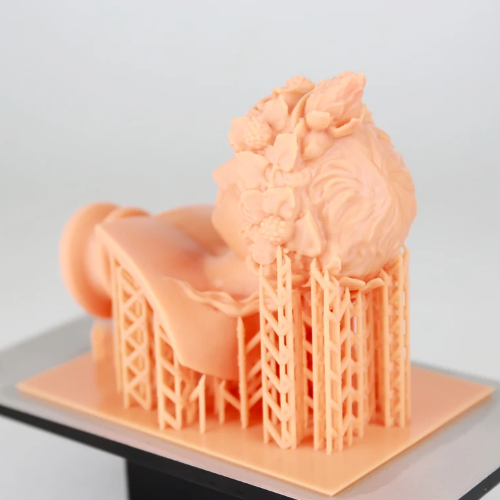

Red wax

Excellent flowability, minimal shrinkage, color consistency.

$

More details

A variety of plastic materials can be used for 3D printing, including PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), PETG (Polyethylene Terephthalate Glycol), TPU (Thermoplastic Polyurethane), Nylon, and more. Each material has its own unique properties and suitability for different applications.

3D printing with plastic materials offers several advantages, including the ability to rapidly prototype and iterate designs, the flexibility to create complex geometries and intricate shapes, and the cost-effectiveness for low-volume production. Additionally, plastic materials are lightweight, durable, and available in a wide range of colors and finishes.

When selecting a 3D printing plastic material, it’s important to consider properties such as strength, flexibility, temperature resistance, chemical resistance, layer adhesion, and surface finish. The specific requirements will depend on the intended application of the printed part.

Yes, 3D printed plastic parts can be suitable for end-use products, particularly in industries where customization, low-volume production, or rapid manufacturing are important factors. With advancements in 3D printing technology and materials, the quality and reliability of printed parts continue to improve, making them viable for various applications.

Address:

Room 101-117(the entire 1st floor), 2nd Building,

Tianxin Industrial Zone, Guxing Community, Xi’xiang Street,

Bao’an District, Shenzhen, China. 518126