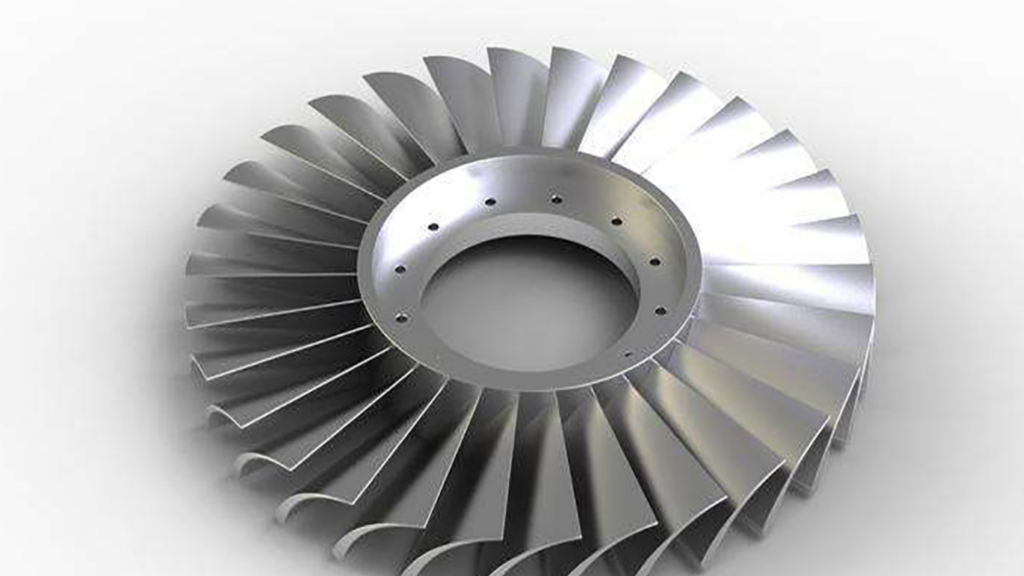

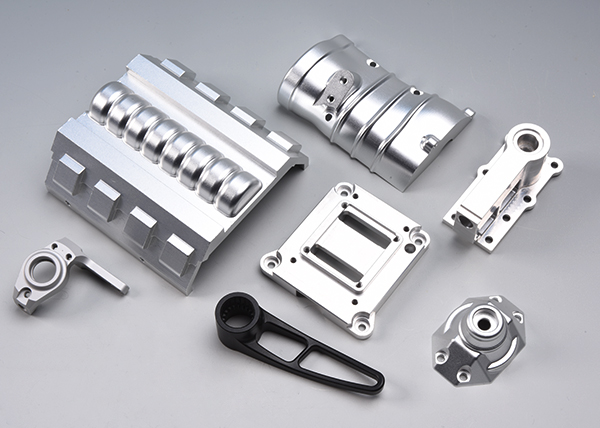

A broad range of metals for CNC machining, from aluminum to titanium, stainless steel to brass, discover the perfect material to bring your CNC machining projects to life.

All drawings are secure and confidential.

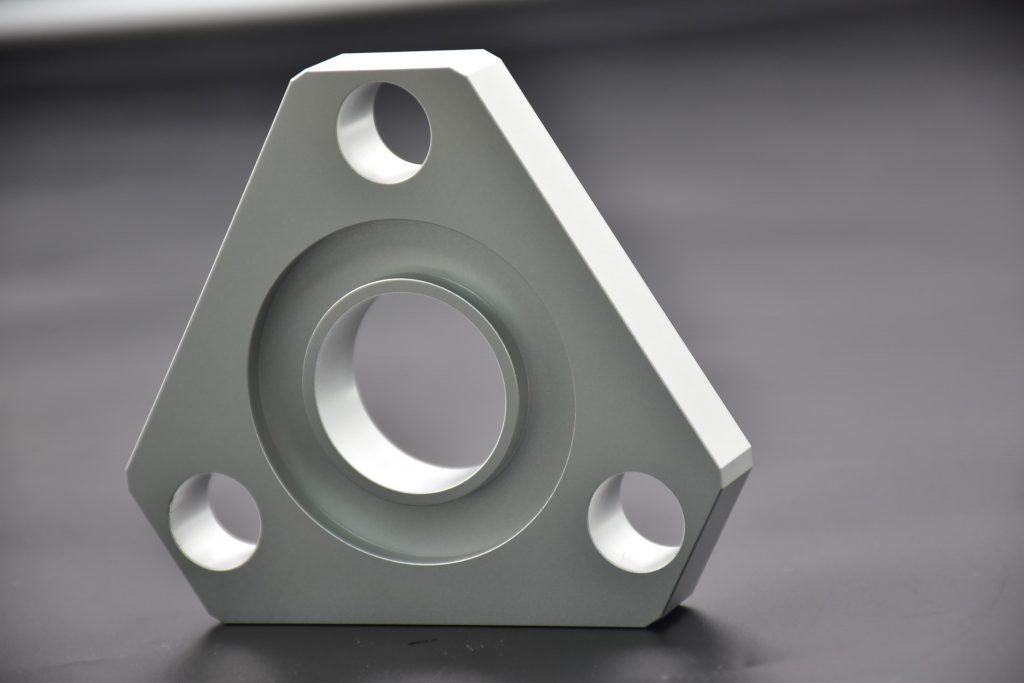

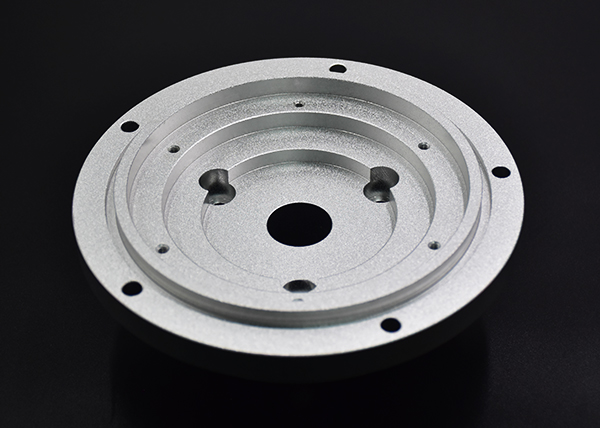

Aluminum

Excellent toughness and wear resistance, it is an all-round material and has been widely used in industry.

$

Stainless steel

High strength and durability, corrosion resistance, temperature resistance.

$$$

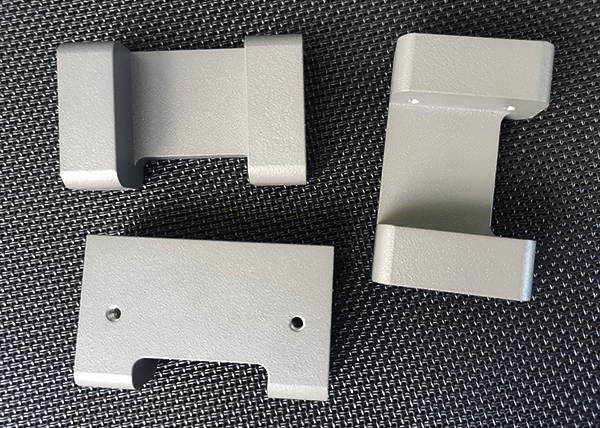

Steel alloys

Ductility and formability, high strength and toughness, fatigue resistance.

$$$

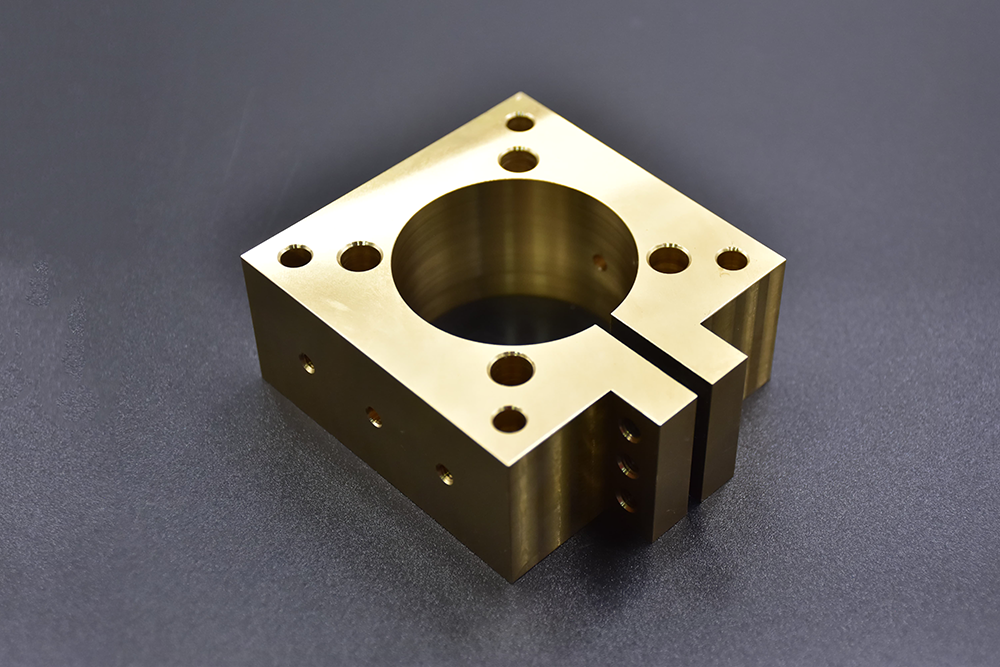

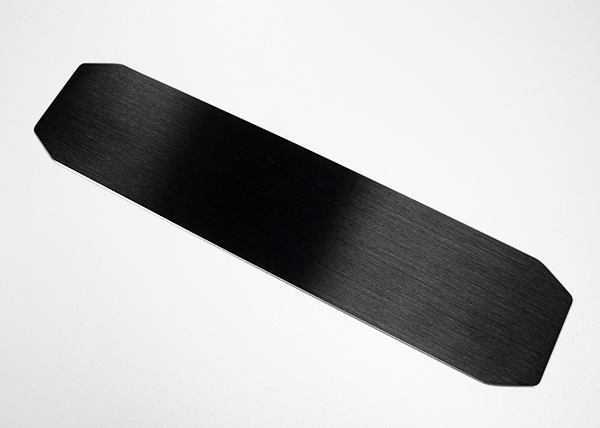

Brass

Excellent machinability, aesthetic appearance, corrosion resistance.

$$

Copper

Superior Electrical Conductivity, thermal conductivity, corrosion resistance.

$$

Bronze

Low friction, great machinability and high wear resistance.

$$

Titanium

Excellent strength-to-weight ratio, corrosion resistance, biocompatibility.

$$$$$

Kovar

Electrical conductivity, corrosion resistance, and low coefficient of thermal expansion.

$$$

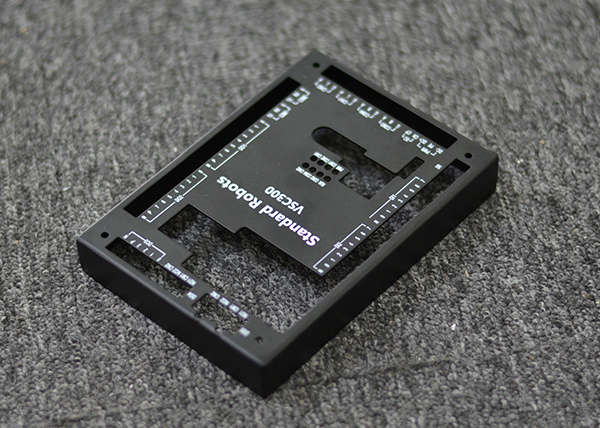

We offer a wide range of surface finishes to these metals for metal CNC machining.

Metals commonly used for CNC machining include aluminum, stainless steel, brass, copper, titanium, and various alloys known for their machinability and strength.

The cost of metal CNC machining varies depending on factors such as the type of metal used, the complexity of the part, tolerances required, surface finishes, and batch size. We provide competitive pricing tailored to your specific project needs. Simply upload a CAD file to get an instant CNC machining quote.

Selecting the right metal depends on factors such as mechanical requirements, environmental conditions, and cost considerations.

Our dedicated team of experts can offer customized recommendations based on your project requirements, including factors such as mechanical properties, surface finish, and budget considerations. Contact support@sogaworks.com to speak to our experts.

Address:

Room 101-117(the entire 1st floor), 2nd Building,

Tianxin Industrial Zone, Guxing Community, Xi’xiang Street,

Bao’an District, Shenzhen, China. 518126