Brass in CNC Machining

Brass has a golden appearance, excellent durability and workability. Brass can be machined into high-performance parts to enhance the functionality of systems.

All drawings are secure and confidential.

Available Alloys And Grades

Brass C26000

C26000 has excellent corrosion resistance, excellent cold workability and good hot formability.

- Tensile strength: 350 MPa

- Yield strength: 135 MPa

- Elongation at break: 55%

Brass C27400

C27400 is corrosion-resistant and wear-resistant, and has good mechanical properties.

- Tensile strength: 355 MPa

- Elongation at break: 20%

- Hardness: 50 HB

Brass C28000

C28000 has high strength, ,ductility, good machinability and corrosion resistance.

- Tensile strength: 420 MPa

- Yield strength: 240 MPa

- Elongation at break: 33%

Brass C36000

C36000 has high strength, high hardness, wear resistance and corrosion resistance.

- Tensile strength: 320 MPa

- Yield strength: 120 MPa

- Elongation at break: 15%

* Generalized values. For reference only.

Finishes And Post-Processing Options

We offer a wide array of surface finish options for your selection, each option has its distinguished functions, such as enhancing function, corrosion resistance, and aesthetic appearance. You can choose the better options depending on your project’s requirements.

Anodizing

Chrome plating

Galvanizing

Nickel plating

Painting

Powder coating

Sand blasting

Silk screen

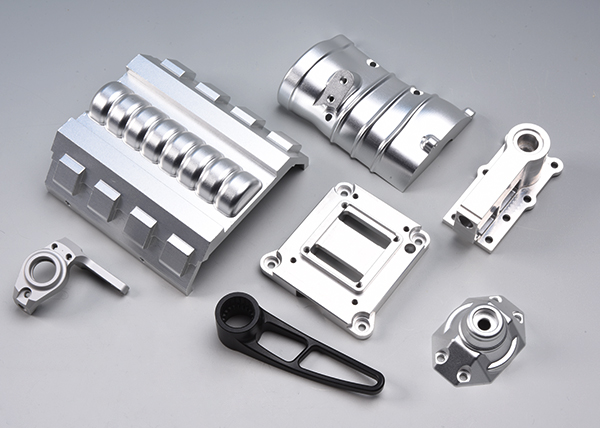

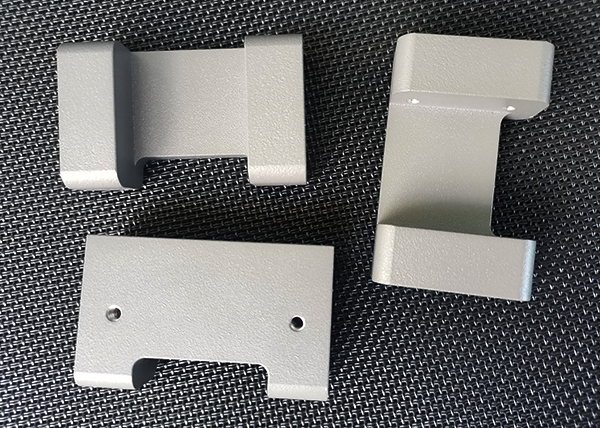

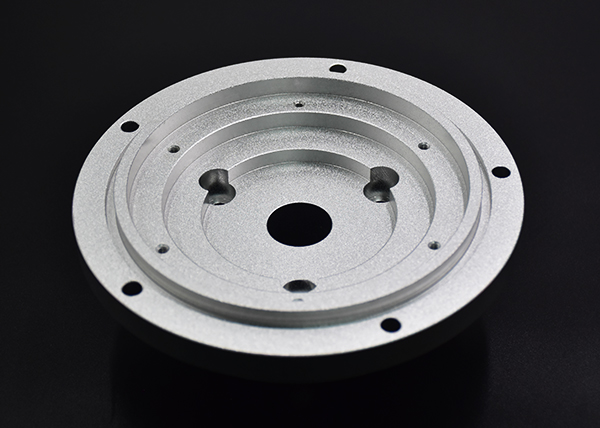

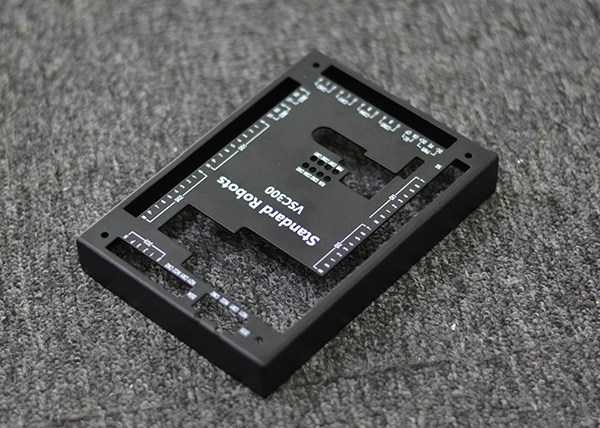

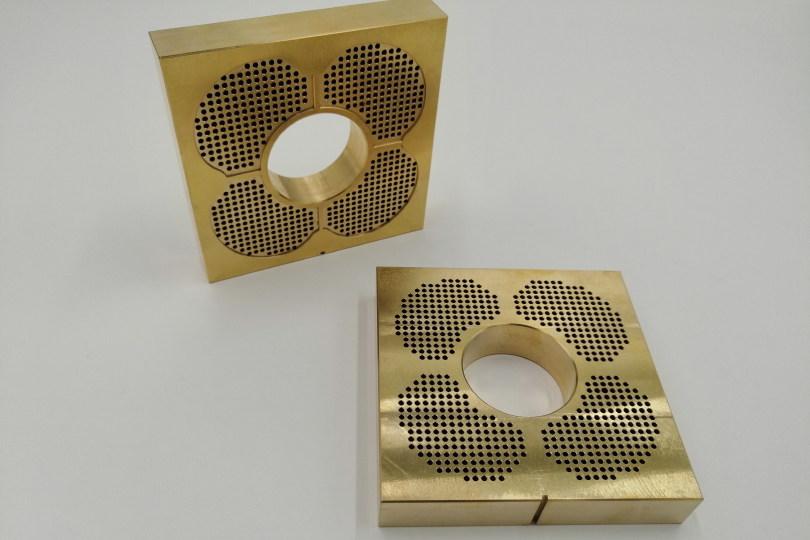

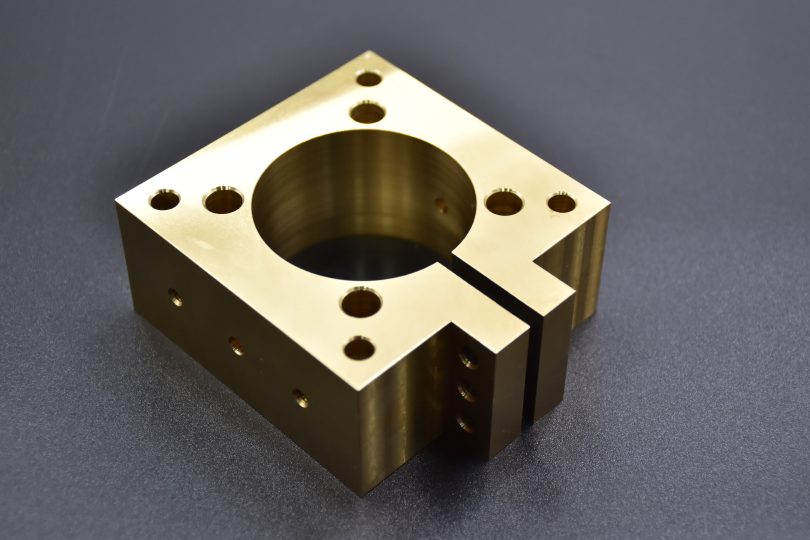

Gallery of CNC Machined Brass Parts

FAQs Aout Brass CNC Machining

We offer CNC machined Brass parts in Brass C26000, C27400, C28000, C36000. Each is widely used in CNC machining for its unique properties. You can choose depending on your custom part’s requirements or contact our expert team for professional advice.

The expense of CNC machining Brass is determined by various factors, including the complexity and dimensions of the component, as well as the specific Brass type employed. These variables have a significant impact on the type of machinery required, the production time, and the cost of the raw materials.

Leveraging advanced machine learning techniques, we are able to compute the precise cost of any machinable part directly from a CAD file. This accurate estimation is based on our extensive experience with millions of CNC machining orders that we have processed in the past. To obtain a quick and accurate quote, simply upload your CAD file and let our system do the rest.

The production time for CNC brass parts depends on several factors, including the complexity of the part, the machine’s capabilities, and the workload of the manufacturing facility. While it’s difficult to provide an exact timeline without specific details, you can upload CAD files to analyze the estimated production time.