Copper in CNC Machining

Copper CNC machining can produce complex copper parts in C110 and C101 which are corrosion resistant and versatile.

All drawings are secure and confidential.

Available Alloys And Grades

Copper C101

C101 is moderate copper with high ductility and impact strength used in engineering applications.

- Tensile strength: 195 MPa

- Elongation at break: 35%

- Hardness: 35 HB

Copper C102

C102 is an oxygen-free copper with better forming, resistance to hydrogen embrittlement.

- Tensile strength: 275 MPa

- Elongation at break: 22%

- Hardness: 85 HB

Copper C110

C110 is the purest grade of oxygen-free copper with Conductivity, corrosion resistance, and ductility.

- Tensile strength: 205 MPa

- Elongation at break: 30%

- Hardness: 35 HB

* Generalized values. For reference only.

Finishes And Post-Processing Options

Surface finishes for copper CNC machining vary depending on the desired aesthetic and functional requirements. You can choose the appropriate surface finishes according to your demands.

Anodizing

Chrome plating

Galvanizing

Nickel plating

Painting

Powder coating

Sand blasting

Silk screen

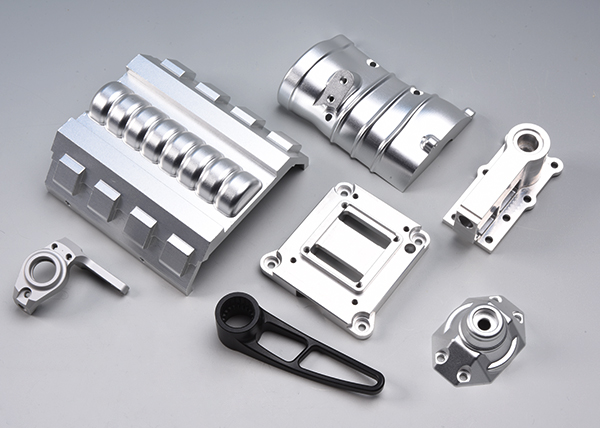

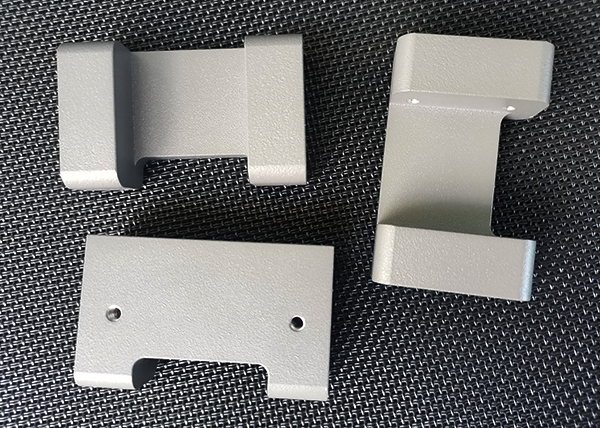

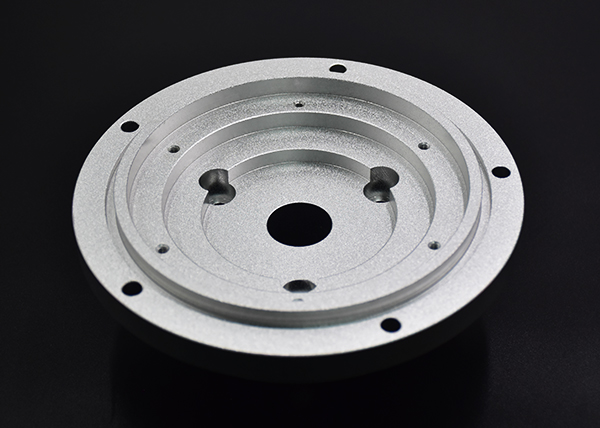

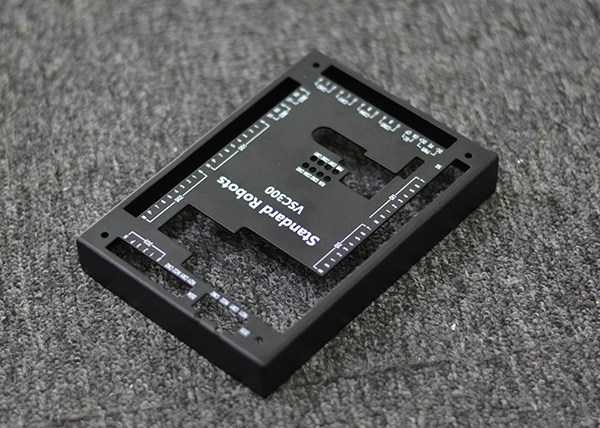

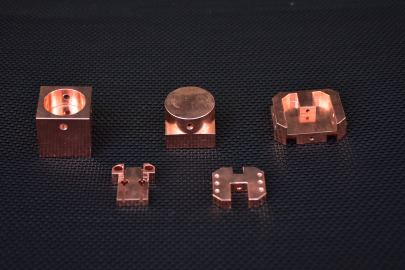

Gallery of CNC machined Copper Parts

FAQs Aout Copper CNC Machining

CNC machining offers several advantages when it comes to working with copper. Firstly, CNC machines provide exceptional precision, allowing for intricate designs and tight tolerances to be achieved with ease. Additionally, CNC machining is highly efficient, enabling rapid production of copper parts with consistent quality. This efficiency is further enhanced by the ability to automate the machining process, reducing labor costs and increasing throughput. Furthermore, CNC machining offers versatility, as it can accommodate various shapes and sizes of copper parts, from simple components to complex geometries.

CNC machining employs computer-controlled precision to ensure dimensional accuracy when working with copper. The process begins with the creation of a digital design file, which specifies the desired dimensions and tolerances of the copper part. This design file is then converted into machine-readable code using CAM (Computer-Aided Manufacturing) software. The CNC machine interprets this code to guide the cutting tools through the material, following the precise geometries outlined in the design file. Throughout the machining process, the CNC machine continuously monitors factors such as tool wear, spindle speed, and feed rate to maintain dimensional accuracy. Additionally, modern CNC machines often feature advanced capabilities such as tool probing and in-process inspection, which further enhance accuracy by verifying dimensions and making real-time adjustments as needed. Overall, the combination of computer control, precise tooling, and monitoring systems ensures that CNC machining consistently delivers copper parts with the desired dimensional accuracy, meeting even the most stringent requirements.

CNC machining is highly efficient for copper. While copper is softer than some metals, CNC machines can precisely control cutting tools, ensuring efficient material removal. Proper tool selection, feeds, and speeds optimize the process for copper, allowing for rapid production with excellent accuracy.