Stainless Steel in CNC Machining

Stainless steel alloys possess exceptional strength, ductility, wear, and corrosion resistance. They can be used in varied industries.

All drawings are secure and confidential.

Available Alloys And Grades

Stainless steel 303

Stainless steel 303 offers exceptional machinability and corrosion resistance.

- Tensile strength: 520 MPa

- Yield strength: 205 MPa

- Elongation at break: 40%

- Hardness: 90 HB

Stainless steel 304

Stainless steel 304 offers versatility with superb corrosion resistance.

- Tensile strength: 520 MPa

- Yield strength: 205 MPa

- Elongation at break:40%

- Hardness: 90 HB

Stainless steel 316

Stainless steel 316 has great corrosion resistance in aggressive environments.

- Tensile strength: 520 MPa

- Yield strength: 205 MPa

- Elongation at break: 40%

- Hardness: 90 HB

Stainless steel 316L

A low-carbon variation of SUS 316, retaining its corrosion resistance with added weldability.

- Tensile strength: 480 MPa

- Yield strength: 177 MPa

- Elongation at break: 40%

- Hardness: 90 HB

Stainless steel 17-4PH

Stainless steel 17-4PH provides high strength and excellent corrosion resistance for demanding applications.

- Tensile strength: 1120 MPa

- Yield strength: 1090 MPa

- Elongation at break: 20%

- Hardness: 30 HRC

Stainless Steel 304L

A low-carbon variant of SUS 304, ensuring enhanced weldability while maintaining corrosion resistance.

- Tensile strength: 520 MPa

- Yield strength: 205 MPa

- Elongation at break: 40%

- Hardness: 90 HB

Stainless steel 410

Stainless Steel 410 is known for its excellent hardness and resistance to corrosion and wear.

- Tensile strength: 540 MPa

- Yield strength: 345 MPa

- Elongation at break: 25%

- Hardness: 159 HB

Stainless steel 430

Stainless Steel 430 offers good corrosion resistance and formability in decorative applications.

- Tensile strength: 450 MPa

- Yield strength: 205 MPa

- Elongation at break: 22%

- Hardness: 183 HB

Stainless Steel 440C

Stainless steel 440C is known for its high hardness and exceptional resistance to abrasion and corrosion.

- Tensile strength: 760 MPa

- Yield strength: 450 MPa

- Elongation at break: 14%

- Hardness: 58 HRC

* Generalized values. For reference only.

Finishes And Post-Processing Options

SogaWorks offers a diverse range of surface finishes specifically designed for stainless steel CNC machining. These options not only enhance the visual appeal but also improve the wear resistance and overall durability of stainless steel parts across our CNC machining capabilities.

Anodizing

Chrome plating

Galvanizing

Nickel plating

Painting

Powder coating

Sand blasting

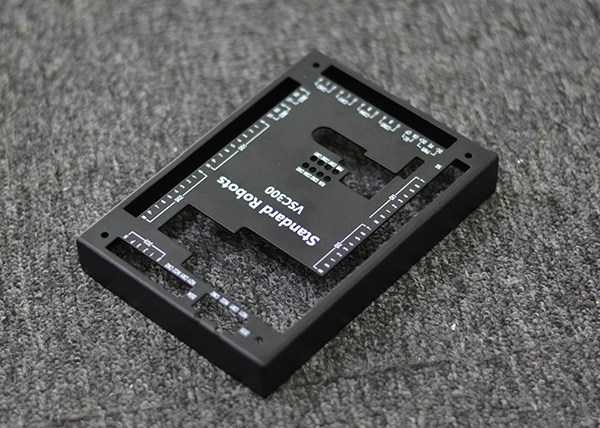

Silk screen

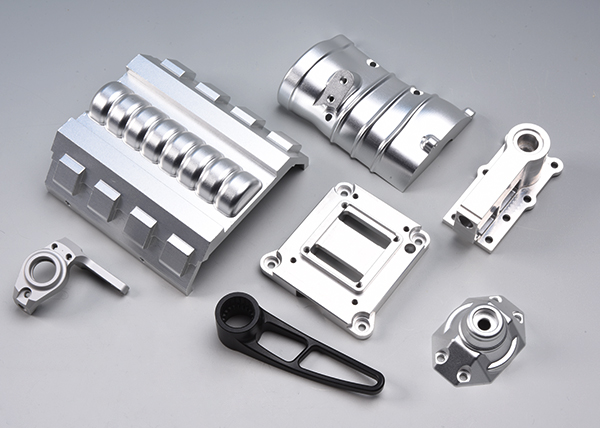

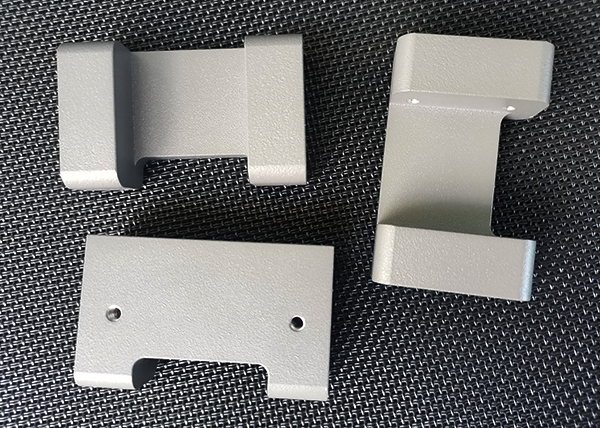

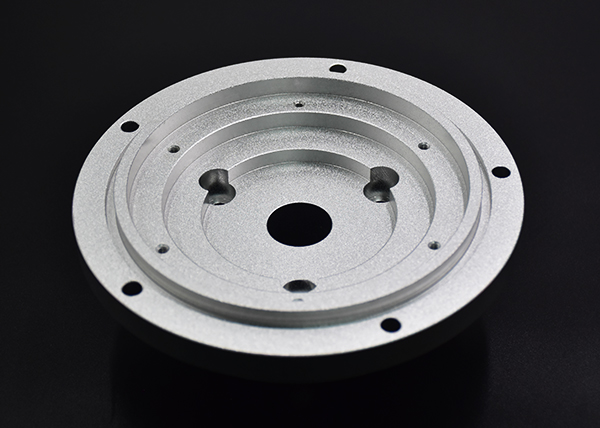

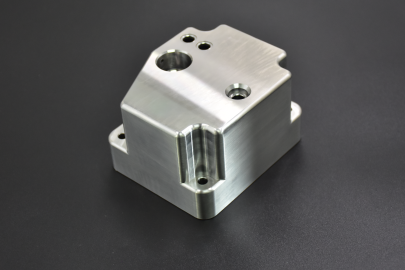

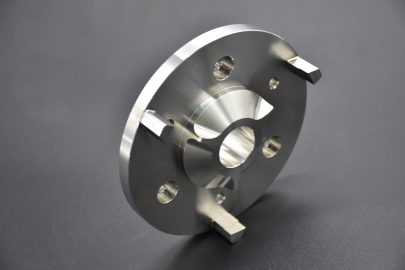

Gallery of CNC machined Stainless Steel Parts

FAQs Aout Stainless Steel CNC Machining

Stainless steel is preferred for CNC machining due to its excellent mechanical properties, corrosion resistance, and durability, making it suitable for various industries such as aerospace, automotive, medical, and more.

The most common stainless steel grades used in CNC machining include 304 and 316 stainless steel. We also provide other grades of stainless steel alloys and each grade offers unique properties suited for specific applications.

Stainless steel’s exceptional hardness necessitates high-quality, robust, and rigid machinery and tooling. Its properties can lead to machine chatter, posing challenges during part machining. Thus it is important to optimize cutting parameters to minimize tool wear and prolong tool life, and implement effective coolant strategies to control heat and chip evacuation.

Yes, stainless steel parts can undergo various post-processing operations after CNC machining. These post-processing steps may include deburring, polishing, passivation, surface treatments such as powder coating or plating, and any other finishing processes required to meet the desired specifications and surface quality standards.