Steel in CNC Machining

Steel CNC machining enables the production of high-performance parts using arbon steel, tool steel, and alloy steel.

All drawings are secure and confidential.

Available Alloys And Grades

Steel 1045

Medium carbon steel with excellent strength, toughness, and wear resistance, suitable for shafts, gears, and machinery parts.

- Tensile strength: 600 MPa

- Yield strength: 355 MPa

- Elongation at break: 16%

- Hardness: 229 HB

Steel 1215

Free-cutting steel with high machinability, this alloy is ideal for intricate parts requiring precision machining.

- Tensile strength: 540 MPa

- Yield strength: 415 MPa

- Elongation at break:10%

- Hardness: 85 HB

Steel 4130

Chromium-molybdenum alloy steel known for its exceptional strength, weldability, and versatility in aerospace.

- Tensile strength: 930 MPa

- Yield strength: 735 MPa

- Elongation at break: 12%

- Hardness: 229 HB

Steel 4140

Chromium-molybdenum alloy steel with high tensile strength, toughness, and good fatigue resistance.

- Tensile strength: 1080 MPa

- Yield strength: 930 MPa

- Elongation at break: 12%

- Hardness: 217 HB

Steel 4340

Nickel-chromium-molybdenum alloy steel offering high strength, toughness, and ductility.

- Tensile strength: 980 MPa

- Yield strength: 835 MPa

- Elongation at break: 12%

- Hardness: 269 HB

Steel 5140

Chromium alloy steel with good hardenability and strength, commonly used in machinery parts.

- Tensile strength: 980 MPa

- Yield strength: 785 MPa

- Elongation at break: 9%

- Hardness: 207 HB

* Generalized values. For reference only.

Finishes And Post-Processing Options

SogaWorks offers a broad selection of surface finishes tailored for steel CNC machining, catering to various needs and preferences. Whether it’s achieving a mirror-like polish for a sleek appearance or applying specialized coatings for enhanced wear resistance, we ensure that every steel part meets high standards of quality.

Anodizing

Chrome plating

Galvanizing

Nickel plating

Painting

Powder coating

Sand blasting

Silk screen

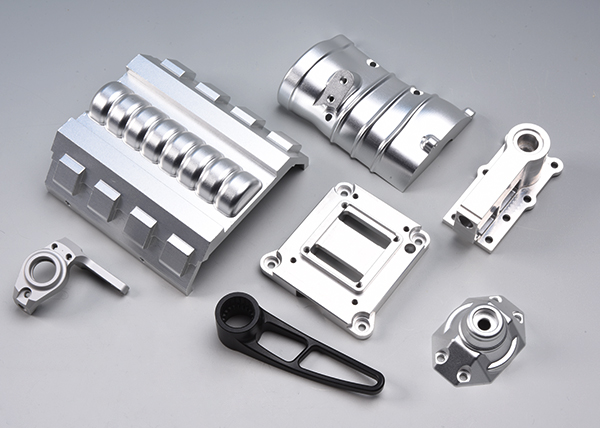

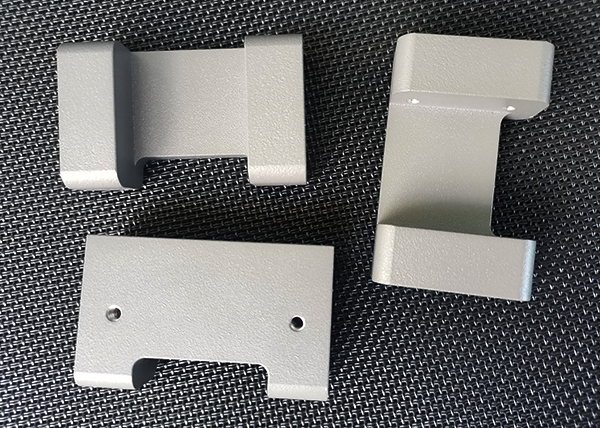

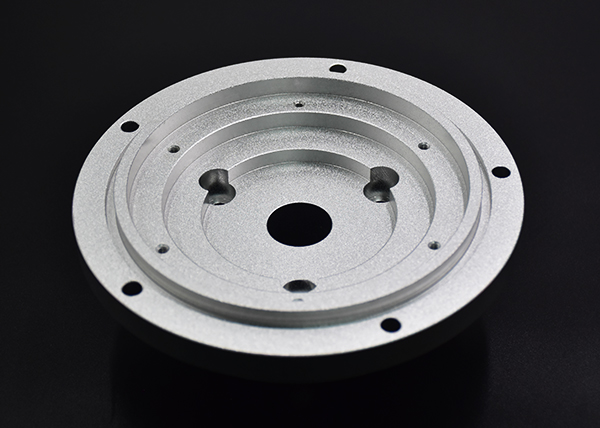

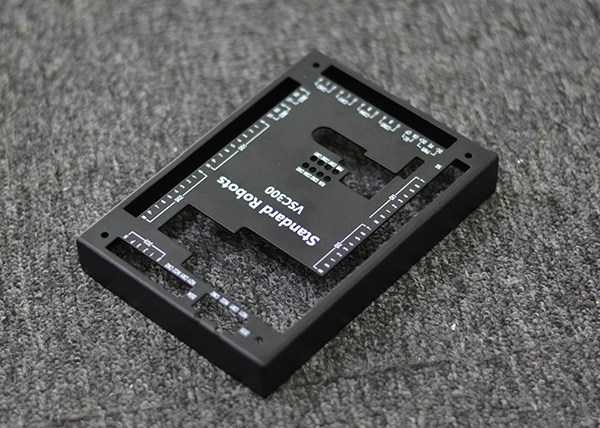

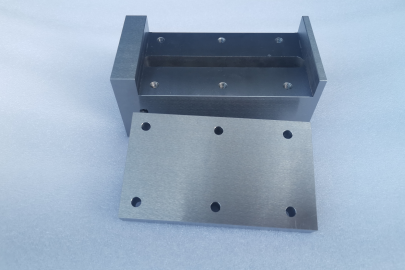

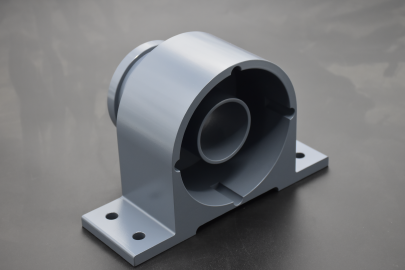

Gallery of CNC machined Steel Parts

FAQs Aout Steel CNC Machining

Common steel materials used in CNC machining include carbon steel(1045), alloy steel(4130, 4140), and various specialized grades tailored for specific applications.

Key considerations include selecting the appropriate steel grade based on the application requirements, optimizing cutting parameters to minimize tool wear and prolong tool life, and implementing effective cooling strategies to control heat generation during machining.

CNC machining steel offers high precision, tight tolerances, and the ability to produce complex geometries with excellent repeatability, making it ideal for manufacturing high-quality components for diverse industries.