Explore our extensive selection of plastics for CNC machining, from ABS to PEEK, discover a diverse range of high-quality plastics engineered to meet the requirements.

All drawings are secure and confidential.

PE

Lightweight, chemical resistance, excellent impact strength, recyclable.

$

More details

Nylon

High strength-to-weight ratio, abrasion resistance, low friction, versatile.

$

PC

High impact resistance, optical clarity, temperature resistance, easy to mold.

$$$

More details

PEEK

High temperature resistance, chemical resistance, excellent mechanical properties, lightweight.

$$$$$

More details

PMMA

Optical clarity, weather resistance, lightweight, easy to shape.

$

More details

PTFE

Low friction, chemical resistance, high temperature resistance, non-stick.

$$$$

More details

PP

Lightweight, chemical resistance, moisture resistance, recyclable.

$

More details

PPS

Flexible, abrasion resistance, chemical resistance, impact resistance.

$$

More details

PVC

Durability, chemical resistance, flame retardant, cost-effective.

$

More details

PU

Flexible, abrasion resistance, chemical resistance, impact resistance.

$$

More details

Bakelite

Electrical insulation, heat resistance, dimensional stability, durability.

$$

More details

Garolite G10

Electrical insulation, mechanical strength, flame resistance, dimensional stability.

$$

More details

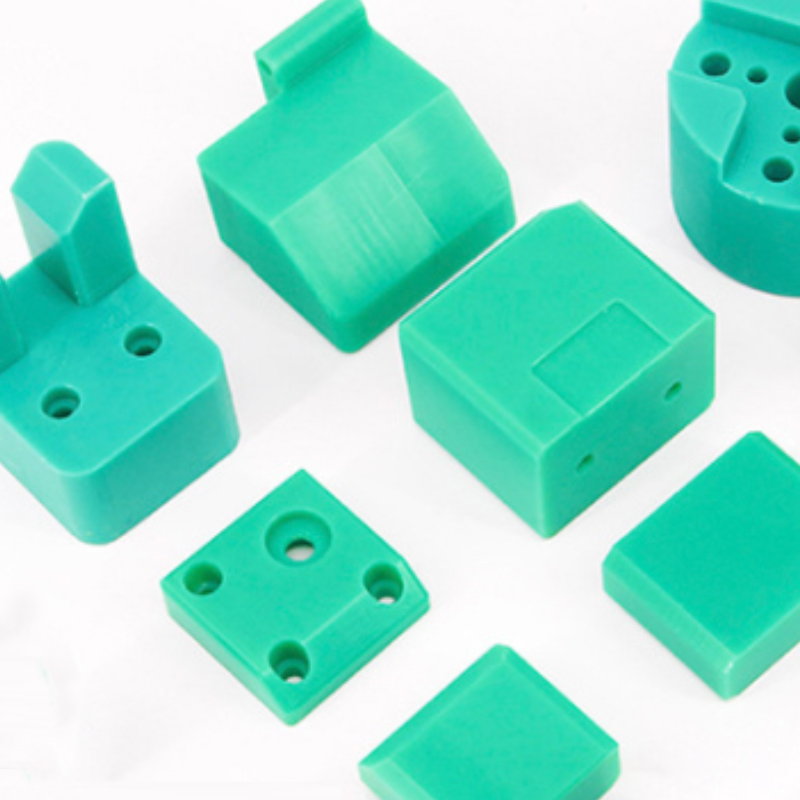

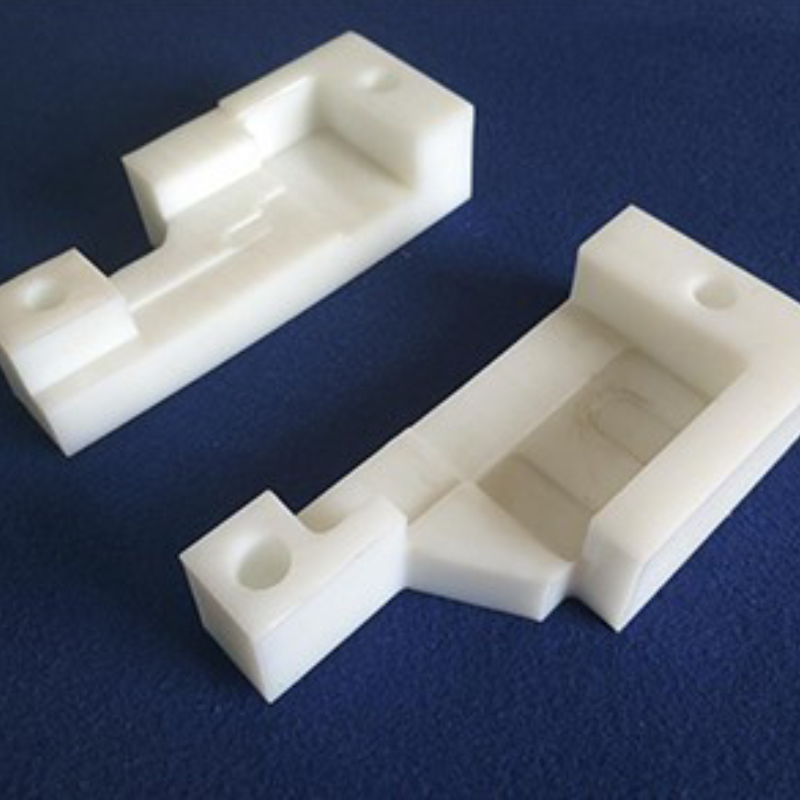

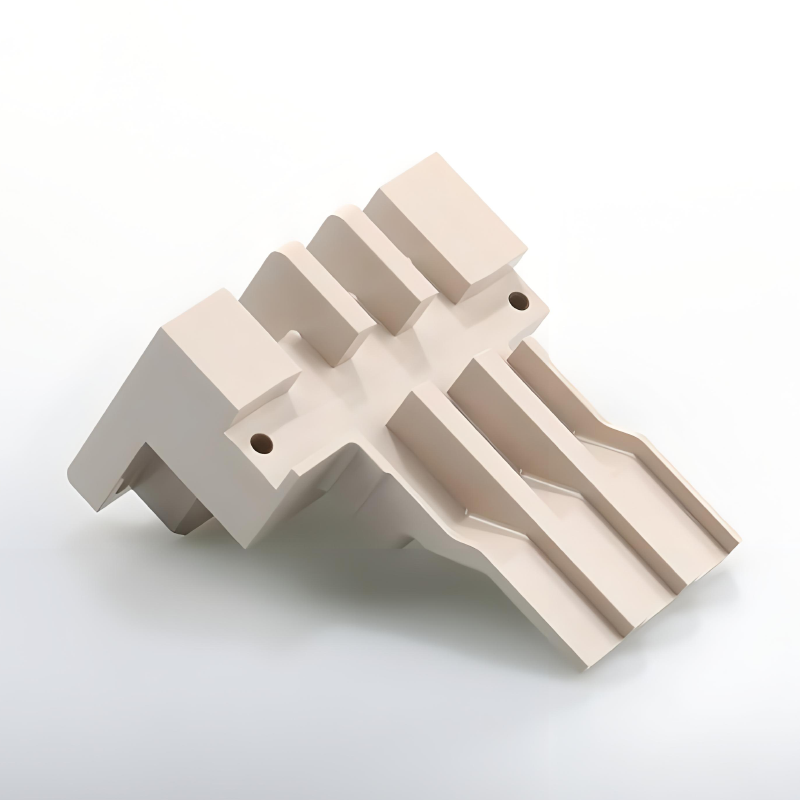

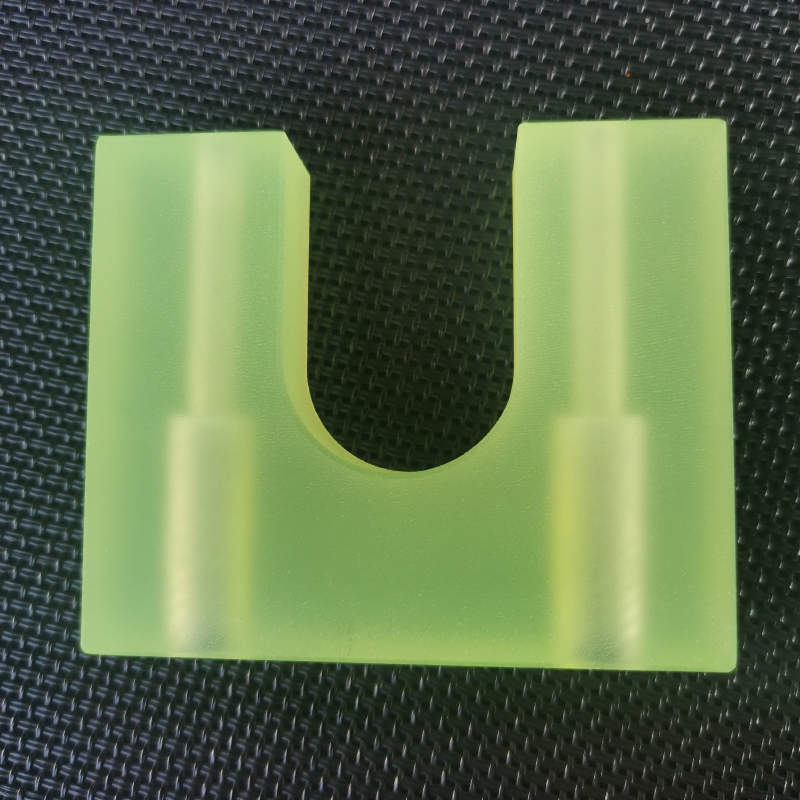

We offer a wide range of surface finishes for your plastic CNC machining parts.

Plastics commonly used for CNC machining include ABS (Acrylonitrile Butadiene Styrene), acrylic (PMMA), nylon, polycarbonate (PC), POM (Polyoxymethylene), and PEEK (Polyether Ether Ketone), among others.

The cost of metal CNC machining varies depending on factors such asChoosing the right plastic material depends on factors such as mechanical properties, chemical resistance, thermal stability, and cost considerations. Contact our experts via support@sogaworks.com to select the optimal plastic material based on your project requirements. the type of metal used, the complexity of the part, tolerances required, surface finishes, and batch size. We provide competitive pricing tailored to your specific project needs. Simply upload a CAD file to get an instant CNC machining quote.

The cost of plastics CNC machining can vary based on several factors including the type of plastic material used, the complexity of the part design, tolerances required, surface finishes, batch size, and machining time. Generally, plastics CNC machining is more cost-effective compared to machining metals, but the final cost depends on the specific requirements of your project. l depends on factors such as mechanical requirements, environmental conditions, and cost considerations.

Yes, CNC machined plastics can be finished with various surface treatments and textures, including polishing, sanding blasting, painting and silk screen, to achieve desired aesthetics and functional properties.

Address:

Room 101-117(the entire 1st floor), 2nd Building,

Tianxin Industrial Zone, Guxing Community, Xi’xiang Street,

Bao’an District, Shenzhen, China. 518126