Our material range encompasses a variety of metals including stainless steel, aluminum, copper, and brass, each chosen for its unique properties and suitability for diverse applications.

All drawings are secure and confidential.

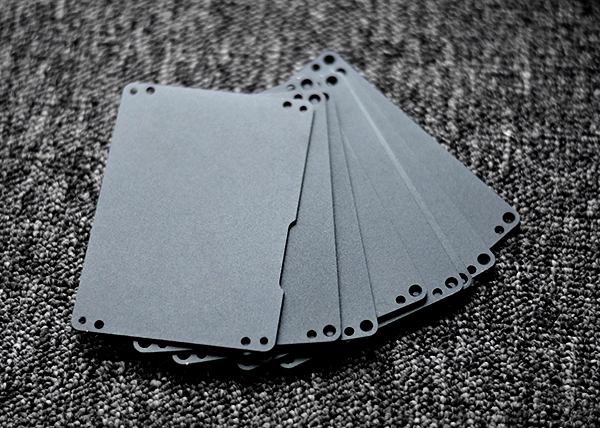

Aluminum

High strength-to-weight ratio and excellent wear resistance.

$

More details

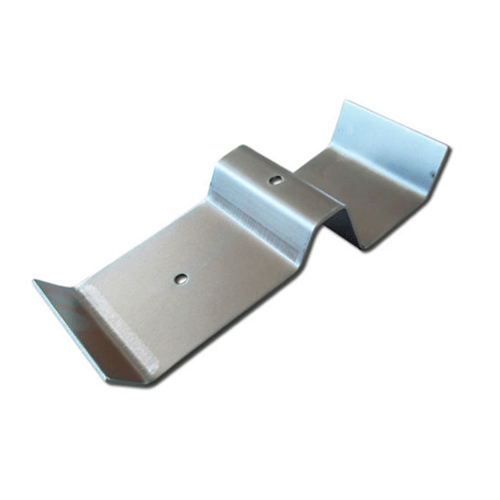

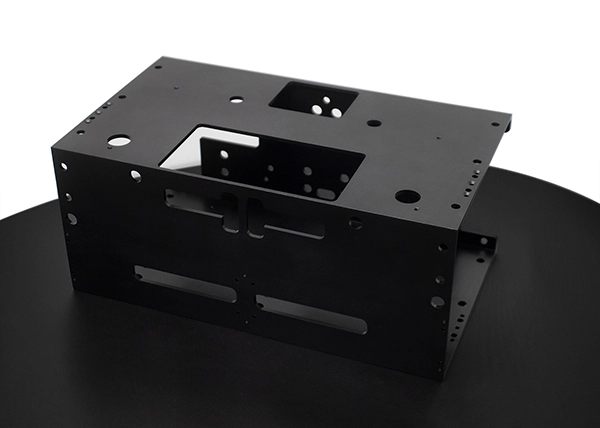

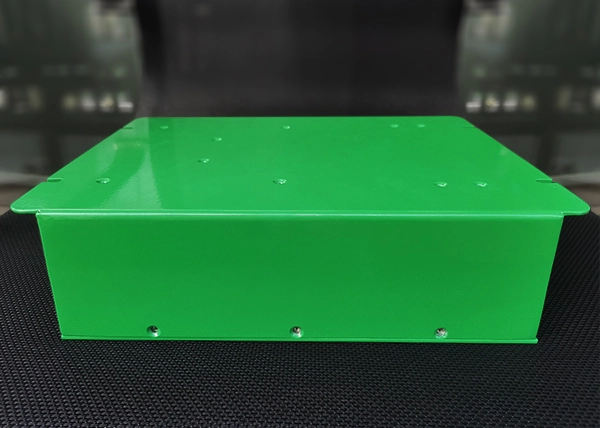

We offer a wide range of surface finishes for sheet metal fabrication parts.

The most common materials used in sheet metal fabrication include steel (carbon steel, stainless steel), aluminum, copper, brass, and various alloys such as titanium alloys.

Steel offers high strength, durability, and excellent weldability, making it suitable for structural applications. Aluminum is lightweight, corrosion-resistant, and offers good thermal and electrical conductivity, making it ideal for applications requiring lightweight components or high corrosion resistance.

Stainless steel offers superior corrosion resistance, high strength-to-weight ratio, and excellent mechanical properties at both high and low temperatures. It is commonly used in industries such as aerospace, automotive, food processing, and medical equipment where hygiene, durability, and corrosion resistance are critical.

Surface finishes such as painting, powder coating, anodizing can be applied to sheet metal parts to enhance appearance, corrosion resistance, and durability. It is essential to choose surface treatment methods based on the material properties and desired finish requirements.

Address:

Room 101-117(the entire 1st floor), 2nd Building,

Tianxin Industrial Zone, Guxing Community, Xi’xiang Street,

Bao’an District, Shenzhen, China. 518126