Steel is an alloy made by blending different base metals with certain alloying elements. There are numerous types of stainless steels with different properties, but they all have one thing in common: the addition of chromium, which imparts corrosion resistance. One of the most recognizable types of stainless steel, 304 stainless steel, is widely used throughout numerous industries.

This article will give you an overview of 304 stainless steel properties. This article will provide you with a structured way to think about these properties so you can easily understand the core aspects of 304 stainless steel. After the fold, we will briefly touch upon composition, Physical properties and mechanical properties.

What is 304 Stainless Steel?

304 stainless steel is defined by ASTM A240/A240M standard covering plain carbon solid solution strengthened austenitic stainless steel with moderate to high strength, typically used in pressure vessel service above 500 °F (260 °C). 304 stainless steel is also known as “18-8 stainless steel” because it typically contains 18% chromium and 8% nickel by mass.

304 stainless steel is one of the most commonly used austenitic stainless steels. It has excellent corrosion resistance, formability and mechanical properties at elevated temperatures. In the annealed condition, 304 stainless steel is non-magnetic.

304 Steel Composition

The chemical makeup of 304 stainless steel is controlled to provide properties ranging from good to superior in corrosion resistance and strength. Below is the core composition of 304 stainless steel according to the standard of ASTM.

| Iron | Cr | Ni | C | Mn | Si | P | S |

| Balance | 18~20% | 8~10.5% | ≤0.08% | ≤2% | ≤1% | ≤0.045% | ≤0.03% |

Impact of Composition on Properties:

- Corrosion Resistance: The high chromium content (18–20%) provides for the development of a self-repairing chromium oxide film that passivates the steel in a wide range of oxidizing environments, including acids and atmospheric corrosion.

- Austenitic Structure: The nickel content (8–10.5%) stabilizes the face-centered cubic (FCC) austenitic phase. This provides the nonmagnetic and good ductility characteristics of 304 stainless steel, even at cryogenic temperatures.

- Weldability and Strength: The low carbon content (≤0.08%) minimizes the formation of chromium carbides and associated localized corrosion in the heat-affected zone of the welded area.

Properties of 304 Stainless Steel

Managerial understanding of physical and mechanical characteristics remains vital for examining 304 stainless steel properties. This part explores the individual characteristics which determine 304 stainless steel performance as well as its applicable range.

| Property | Value |

| Tensile Strength | 515 MPa |

| Yield Strength | 205 MPa |

| Elongation | 70% |

| Modulus of Elasticity | 193 GPa ~ 200 GPa |

| Shear Modulus | 86 GPa |

| Hardness | 123 HB |

| Thermal Conductivity | 16.2 W/m·K |

| Density | 7.93 g/cm³ |

| Magnetism | Nonmagnetic |

Is 304 Stainless Steel Magnetic?

The question of magnetism frequently perplexes people about 304 stainless steel. The heat-treated state of 304 stainless steel demonstrates no magnetic properties. Cold working through processes such as rolling and bending and forming introduces magnetism because it converts some austenite into the magnetic phase known as martensite. Higher levels of cold work lead to amplified transformation of the material.

Density

The measurement for 304 stainless steel density shows 7.93 g/cm³ as its value. The density value for austenitic stainless steels matches this specific level which determines their mass properties along with structural strength.

Thermal Conductivity

At 20°C the thermal conductivity value for 304 stainless steel measures 16.2 W/(m·K). Stainless steel 304 shows excellent suitability for applications needing efficient heat transfer because of its thermal conductivity properties in heat exchangers and boiler components.

Tensile Strength

The ultimate tensile strength (UTS) of 304 stainless steel reaches values of at least 515 MPa. The material experiences maximum stress up to this point before breaking. The high tensile strength enables 304 stainless steel to handle heavy loads before breaking which makes it perfect for use in structure design.

Yield Strength

The minimum yield strength of 304 stainless steel amounts to 205 MPa. The material begins to show permanent shape distortion when subjected to this specific level of stress. After exceeding this threshold the material stays permanently distorted when the external force is released. Designers use yield strength as an essential factor to prevent parts from deforming when exposed to operational forces.

Elongation

The elongation value of 304 stainless steel reaches 70% when measured over a gauge length of 50 mm (2 inches). The material demonstrates outstanding ductility through its high elongation percentage which enables deformation before failing. Applications that need material deformation through forming and bending or stretching methods succeed because of ductility properties in the material.

Hardness

304 stainless steel Hardness measurement through Brinell Hardness (HB) test shows values that do not exceed 187. Moving forward the material attains a dual benefit of combined wear protection and malleability. 304 stainless steel maintains an appropriate hardness that fits many general-purpose uses where moderate resistance against wear serves the purpose.

Make Your Idea Take Shape!

Modulus of Elasticity

Young’s modulus elasticity in the 304 stainless steel material exists between 193 GPa and 200 GPa. The material shows high elasticity stiffness together with elastic deformability resistance because of its high modulus value. The application of load enables 304 stainless steel to achieve stable structures by maintaining its shape.

Shear Modulus

The shear modulus (modulus of rigidity) in 304 stainless steel amounts to 86 GPa. The material resistance measurement as shear modulus takes place through parallel application of shear stress that allows material layers to slide relative to each other. The excellent torsional load resistance of 304 stainless steel originates from its high shear modulus that allows builders to create rigid solid structures used for shafts fasteners and piping applications.

Impact Toughness

The Charpy impact assessment finds that 304 stainless steel achieves excellent results for determining impact toughness properties. This material absorbs energy well during abrupt impact events to prevent damage from taking place. Maintaining good impact toughness in applications becomes essential because operational dependability can be achieved when safety protocols are implemented.

In conclusion, the industrial applications adopt 304 stainless steel materials because the material demonstrates reliable physical characteristics together with superior mechanical properties. The material finds extensive use in construction works and automotive engineering and food processing applications and medical equipment production because it demonstrates annealed state non-magnetism alongside excellent mechanical substrates and ductility and impact toughness properties. The accurate properties serve as groundwork to determine appropriate applications for 304 stainless steel and extend its operational lifetime.

Does 304 Stainless Steel Rust?

Amid its corrosion resistance mechanisms the active layer stems from 304 stainless steel because chromium promotes surface formation of this protective oxide film. The protective surface film creates a shield that separates the metal from harmful oxygen and moisture and acidic substances. The properties of 304 stainless steel cannot prevent every type of corrosion when operating under particular environmental conditions.

Corrosion Mechanisms

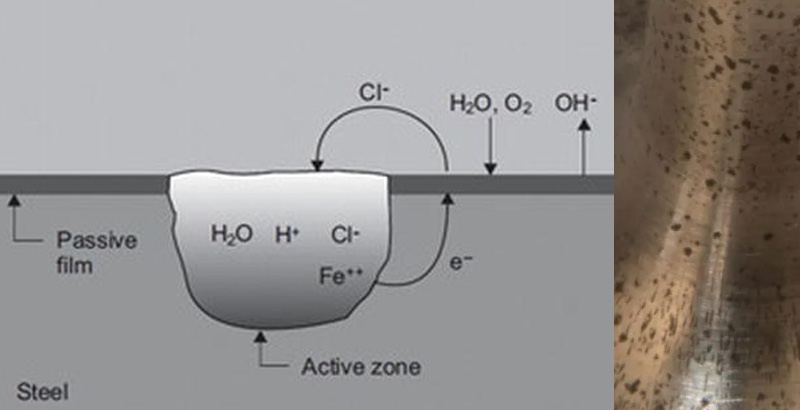

- Passive Layer Formation: A chromium content higher than or equal to 18% in 304 grades generates an adherent oxide layer through oxygen reaction that maintains itself after surface damage.

- Pitting Corrosion: The high chloride concentrations present in seawater destroy the passive layer surface which results in localized pitting corrosion. An increase in risk of pitting occurs when chloride levels are high and the temperature is hot and the area poorly ventilated.

- Crevice Corrosion: Tightning spaces such as gaps in fasteners prevent corrosive agents from escaping which speeds up localized breakdown of the passive layer.

Rust Conditions

- High-Chloride Environments: Pitting corrosion initiation occurs in environments with chloride levels above 35 ppm such as seawater exposure and salt spray conditions as well as deicing salts.

- Weld Decay: Weld Decay occurs when welding heat leads to chromium carbide precipitation in the heat-affected zone that causes passive layer depletion and material weakness.

- Mechanical Damage: Bare metal becomes accessible when improper cleaning or surface scratches or mechanical abrasions occur which permits corrosion to start.

Equivalent Grades of 304 Stainless Steel

| USA(ASTM) | China(GB) | Japan(JIS) | EU(EN) | Germany(DIN) | Russia(GOST) | ISO |

| 304 | 06Cr19Ni10 | SUS304 | 1.4301 | X5CrNi 18-10 | 08Х18Н10 | X5CrNi 18-10 |

304 vs 304L Stainless Steel

The leading difference between 304 and 304L grades exists due to carbon content since this variation controls mechanical properties alongside corrosion resistance characteristics of 304 stainless steel.

Composition Differences

- 304: Carbon content ≤0.08% (max).

- 304L: Carbon content ≤0.03% (max).

Corrosion Resistance

Weldability of 304L stainless steel improves because lower carbon content prevents weld heat-affected zones from developing chromium carbides and thus prevents intergranular corrosion in chloride containing environments.

Thermal post-weld annealing needs to be routinely performed on 304 steel to stop intergranular corrosion from happening.

Mechanical Strength

The tensile strength of 304 steel achieves its highest point within the temperature range of 800°F and 427°C because it contains 0.04 to 0.10 percent carbon content.

At room temperature, the yield strength of 304L shows a minor reduction compared to 304 yet both grades have similar basic strength properties.

Weldability

Welded constructions located in corrosive environments should utilize the 304L steel grade because this material shows excellent protection against intergranular corrosion.

Non-critical welded structures made from 304 material benefit from good weldability after post-weld annealing becomes possible.

| Property | Stainless Steel 304 | Stainless Steel 304L |

| Tensile strength | 515 MPa | 485 MPa |

| Yield strength | 205 MPa | 170 MPa |

| Elongaiton | ≥ 40% | ≥ 40% |

| Hardness | 123 HB | 123 HB |

Applications

304: This material serves industrial purposes which include food equipment and kitchenware products and building material and structural components exposed to average corrosion areas.

304L: The material finds its place within sites requiring advanced corrosion resistance and welding possibilities in pressure vessels and heat exchangers and pharmaceutical equipment systems.

Engineers along with designers select suitable 304 stainless steel grades using a balanced analysis of resistance properties combined with mechanical characteristics and cost requirements for particular situations.

Applications of 304 Stainless Steel

The material 304 stainless steel demonstrates exceptional properties that lead to its expansive industrial applications because of its capability to resist corrosion and maintain formability and its acid-resistant characteristics. The material suits multiple applications because it demonstrates durable service combined with sanitary performance and pleasing visual characteristics.

Architecture & Construction

- Structural Elements: Stainless steel railings along with balustrades and staircases use 304 material because it delivers weather resistance together with an attractive visual appearance.

- Cladding & Facades: The harsh environmental factors such as salt spray and pollution do not affect curtain walls and roofing systems because of 304 stainless steel’s excellent corrosion resistance properties.

Chemical & Energy Sectors

- Heat Exchangers: Tubular and plate-type exchangers in petrochemical facilities about thermal conductive properties which resist scale formation.

- Pressure Vessels: The storage of corrosive chemicals and high-pressure gas systems requires a material which is both ductile and tensile. Therefore, pressure vessels are specified as 304.

Transportation & Automotive

- Exhaust Systems: A combination of mufflers and catalytic converters to exhaust pipes are stricken with corrosion by 870°C temperatures, 304 is the solution.

- Marine Applications: Seawater resistant fasteners or any other railings and ship fittings for that matter, 304 stainless steel has the ability to resist chloride-ion corrosion.

Household & Consumer Goods

- Cookware: Food-grade 304 stainless steel meets the heavy metal precipitation standards specified by ASTM and other regulations. It can be used to make cookware, bathroom equipment, furniture, etc.

- Art & Design: The combination of 304 stainless steel features both excellent workability and pleasing appearance in sculpture installation and signage assignments and architectural building applications.

Such an organized overview demonstrates that 304 stainless steel properties lead to product advantages which establish its central status in engineering projects.

Conclusion

304 stainless steel properties have made it possible for this type of stainless steel to be widely used in industries, and 304 stainless steel pipe, which inherits the excellent properties of 304 stainless steel, has also enjoyed huge popularity. 304 stainless steel properties make it an economic choice for CNC machining projects as well.

The good properties of 304 stainless steel are expected to be extended in the future because the development of green buildings and renewable energy will certainly open up more applications of 304 stainless steel.