The aerospace industry stands at the forefront of innovation and transformation, continuously pushing the boundaries of what is achievable in aviation and space exploration. Within this dynamic sector, one technology has emerged as a driving force for change: Additive Manufacturing. As a disruptive and revolutionary method of production, additive manufacturing, often referred to as 3D printing, has been reshaping the aerospace landscape with its game-changing capabilities. A report from imarcgroup indicates that the global aerospace additive manufacturing market size reached US$ 3.86 Billion in 2022. Looking forward, the market is about to reach US$ 11.08 Billion by 2028.

With a market volume that is steadily growing, additive manufacturing in aerospace has evolved from a promising concept to a critical element in the industry’s pursuit of efficiency and innovation. This article delves into the multifaceted world of additive manufacturing, exploring its applications, advancements, and the transformative impact it has on the aerospace sector.

Benefits of Additive Manufacturing

Additive manufacturing offers many benefits that have reshaped how aircraft and spacecraft are designed and produced.

Rapid Prototyping

3D printing is ideal for rapid prototyping, allowing quick iteration and testing of designs. Aerospace engineers can quickly iterate and prototype new designs facilitating design improvements based on feedback, and reducing development time and costs. This speed is especially valuable in a sector where innovation is a constant driver.

Supply Chain Simplification

3D printing can simplify the supply chain by allowing for on-demand production, reducing the need for extensive inventories and long lead times.

Customization

AM allows for the cost-effective production of custom components or configurations tailored to specific missions, customer requirements, or individual pilot preferences. This level of customization is beneficial for specialized aerospace applications.

Cost Savings

Unlike traditional manufacturing, additive manufacturing does not require expensive molds, dies, or tooling for each new part. This leads to substantial cost savings, especially when dealing with design changes or small production runs.

Challenges for Aerospace Additive Manufacturing

Additive manufacturing technology in the aerospace industry also faces its fair share of challenges, and it demands a forward-looking perspective.

One of the paramount concerns is the certification and regulation of 3D-printed components.

Quality Assurance

Ensuring the quality and reliability of 3D-printed parts is a critical concern. Aerospace components must meet strict standards for safety and performance. Developing and implementing quality control processes for AM parts can be challenging.

Certification and Regulation

In the aerospace industry, one of the biggest challenges with additive manufacturing is certification. Aircraft components must adhere to stringent regulations, ensuring that 3D-printed parts are as safe as those manufactured using traditional methods.

In 2018, SAE International released aerospace materials specifications (AMS) for metal additive manufacturing materials and processes used in critical components for aircraft and spacecraft.

Scalability

While additive manufacturing is ideal for producing complex, low-volume parts, scaling up production can be a problem. Additive manufacturing, which involves building objects layer by layer, is inherently slower to produce than traditional manufacturing methods such as injection molding, casting, or machining.

The true potential of additive manufacturing will be realized when it seamlessly integrates with traditional manufacturing methods for large-scale production. Achieving this integration involves optimizing the manufacturing process, adapting supply chains, and standardizing materials and design practices.

Materials and Processes in Additive Manufacturing

Materials and processes are the cornerstone of additive manufacturing in aerospace, where the quest for lightweight yet robust components is paramount.

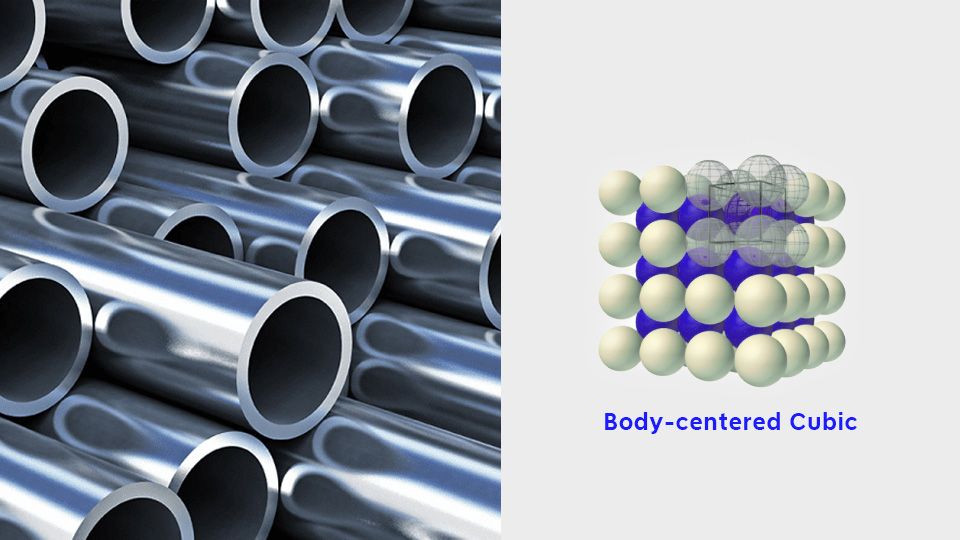

Metal Alloys in Aerospace Additive Manufacturing

Metal alloys play a crucial role in aerospace additive manufacturing, offering a combination of strength, heat resistance, and durability. Titanium and its alloys, like Ti-6Al-4V, are preferred for their lightweight properties and corrosion resistance, commonly used in aircraft frames and engine components. Nickel-based superalloys, such as Inconel and Hastelloy, excel in high-temperature environments, making them essential for jet engine parts and turbine blades. Stainless steel, valued for its corrosion resistance and strength, finds applications in exhaust systems and various structural components. Aluminum alloys are chosen for their lightweight properties and strength, widely used in fuselage sections and interior structures.

Composite Materials in Aerospace Additive Manufacturing

Composite materials used in aerospace additive manufacturing combine lightweight properties with strength, making them ideal for various applications. Carbon fiber-reinforced composites, often combined with thermoplastic polymers, provide the required strength and weight reduction for components like aircraft interiors and structural parts. Advanced ceramics like silicon carbide and alumina offer exceptional thermal and electrical insulation, making them valuable for engine components, insulating materials, and heat shields. Polymer composites, both high-performance polymers and polymer matrix composites, are employed in AM to create lightweight, durable components for aerospace applications, including unmanned aerial vehicles (UAVs) and interior cabin parts. These composite materials are meticulously chosen to meet the specific performance and safety demands of the aerospace industry, whether for structural integrity, weight savings, or resistance to extreme conditions.

Processes in Aerospace Additive Manufacturing

Aerospace additive manufacturing processes play a pivotal role in shaping complex, high-performance components. Direct Energy Deposition (DED) involves feeding metal powder or wire into a high-energy laser or electron beam, allowing the repair and addition of material to existing aerospace parts. Fused Filament Fabrication (FFF) or Fused Deposition Modeling (FDM) extrudes thermoplastic filaments layer by layer, suitable for polymer-based aerospace components and tooling. Powder Bed Fusion (PBF)selectively fuses metal or alloy powders layer by layer to produce high-strength, intricate components. These processes, combined with precise material selection, enable aerospace companies to create components that meet stringent industry standards and withstand the rigors of aerospace applications.

Surface finish is a critical aspect of 3D printing in aerospace. Post-processing techniques like machining, polishing, sanding, and specialized coatings or treatments play a pivotal role in achieving essential surface characteristics such as precise, smooth, and defect-free surfaces. Moreover, advanced technologies, such as heat treatments and surface enhancements, are employed to meet the stringent standards and performance requirements of aerospace applications, ultimately ensuring that 3D-printed components not only meet but often exceed the surface finish expectations within the industry.

Applications of Additive Manufacturing in Aerospace

Additive manufacturing has been integrated across a broad spectrum of aerospace applications.

Lightweight Engine Components

AM allows for the production of complex, lightweight engine parts with intricate internal geometries, improving fuel efficiency and overall performance. GE Aviation is a pioneer in using AM for aerospace engine components. They produce fuel nozzles for their LEAP jet engines using AM. These nozzles are intricate, lightweight, and more efficient, contributing to fuel savings.

Aircraft Interiors

AM is used to manufacture customized, lightweight interior components, such as cabin fittings, seating structures, and ventilation ducts, enhancing passenger comfort and reducing aircraft weight. In the Airbus A350 XWB, the company employed AM to create lightweight, customizable cabin components. These include complex brackets and components for seat fittings, making the aircraft’s interior more comfortable for passengers.

Complex Structural Components

Aerospace companies utilize AM to create intricate and optimized structural components, including airframe brackets, landing gear components, and fuselage sections, leading to weight reduction and improved fuel efficiency. In partnership with Norsk Titanium, Boeing uses AM to manufacture structural components like titanium structural fittings for the 787 Dreamliner. These components are lighter and less expensive to produce while maintaining strength.

Prototyping and Testing

Rapid prototyping and iteration are crucial in aerospace development. AM enables engineers to quickly create and test prototypes, accelerating design and performance optimization. SpaceX utilizes AM for rocket engine development. The SuperDraco engines on the Crew Dragon spacecraft feature AM components. AM allows for rapid prototyping, reducing development time and costs.

Tooling and Fixtures

Custom tooling and fixtures produced through AM streamline manufacturing processes, reducing lead times and improving production efficiency. GE Aviation uses AM to create custom tooling for aircraft engine production. For example, they have produced 3D-printed ultrasonic inspection fixtures that enhance the quality control process for engine components.

Drone and UAV Manufacturing

Unmanned aerial vehicles (UAVs) benefit from AM for creating lightweight, durable components, including airframes, propulsion systems, and sensor mounts. General Atomics uses AM for their MQ-9 Reaper UAVs. Components like sensor mounts and landing gear brackets are produced using AM to reduce weight and enhance durability.