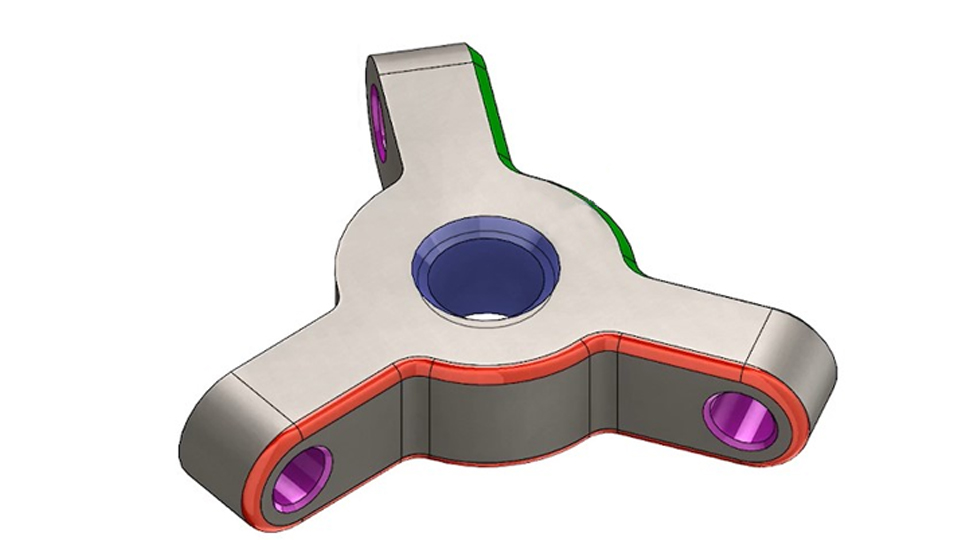

Chamfer and fillet are both commonly used design features with sharp edges. Designers are always confused by these edge features. Although they sound similar, they have different features and uses. This article will discuss the differences between chamfers and fillets and offer some advice on whether to choose between them.

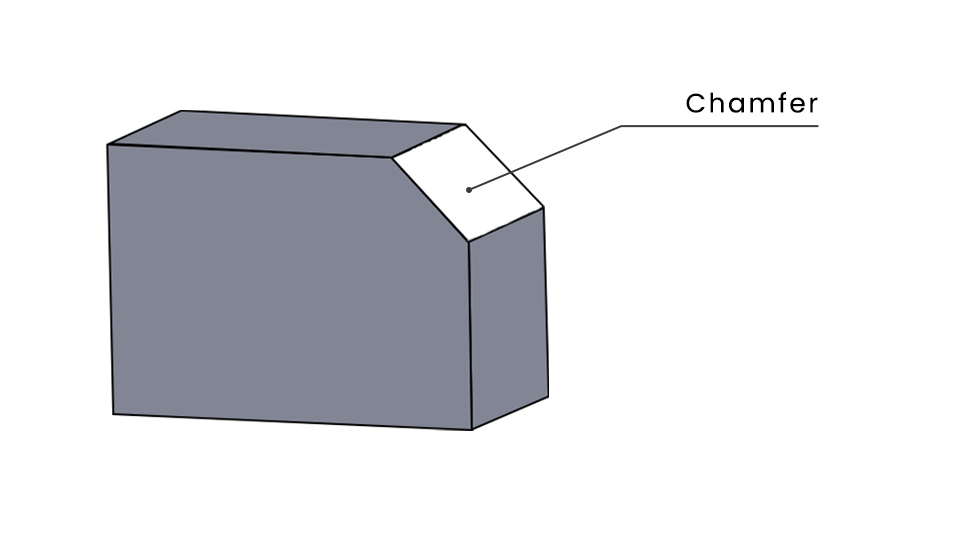

What is Chamfer?

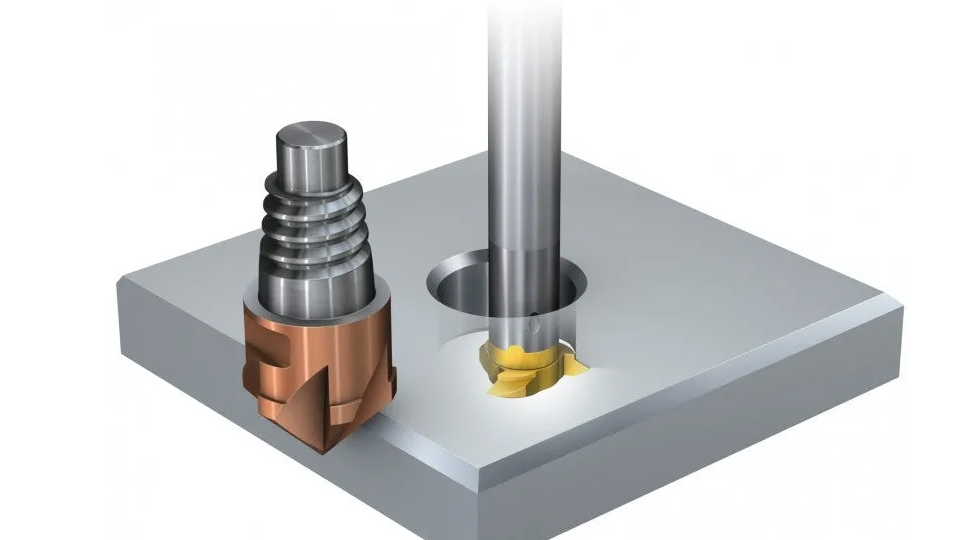

Chamfer is a slop formed by cutting a sharp edge at a certain angle. A common procedure is cutting a right-angle edge into a 45° surface. Charmfering is commonly used to remove burrs caused by machining or to facilitate the connection and assembly of the parts. It is widely used in furniture, printing circuit boards, and more.

Chamfer edges have different angled slopes; common chamfer angles are 45 degrees and 65 degrees.

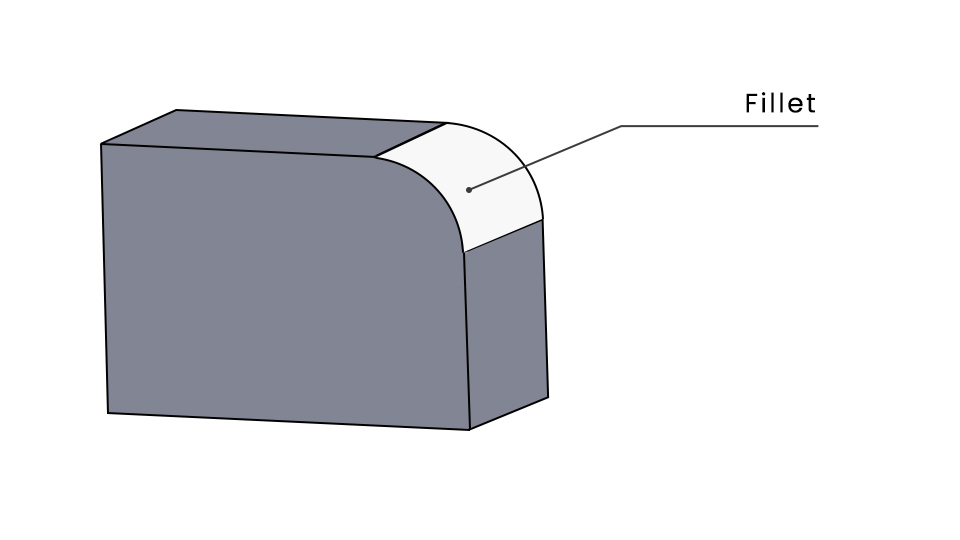

What is Fillet?

Fillet is the arc that creates a smooth transition between the sharp edges of two mating surfaces. Fillet has a radii; it can be either internal or external to the part. Fillets are added to reduce the stress concentration of the edge and extend the lifespan of the part.

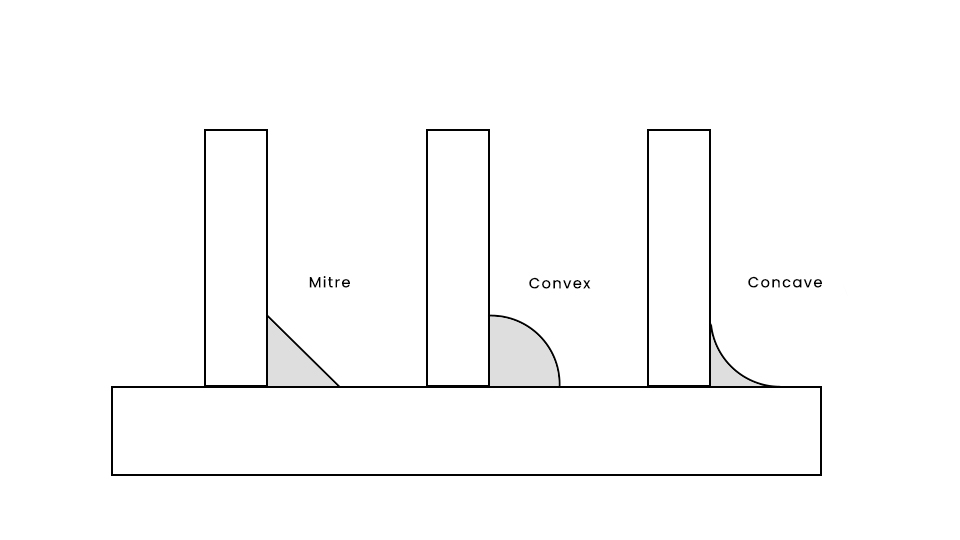

Fillets can be divided into three types by their location: mitre fillet, concave fillet, and convex fillet.

Mitre fillet: Bevel the edges so that the two faces meet at an angle.

Concave fillet: Concave the corner of a shape to form an inward arc.

Convex fillet: Convex the corner of a shape to form an outward arc.

Differences Between Two Edges

Fillets can be easy to confuse with the other edge features, such as chamfers and bevels. The main geometric difference is that fillets have arcs while others do not. In addition, some other key features make fillet different from chamfer.

Geometric Shape

Fillets have no obvious turning points and use a continuous arc to connect different surfaces. This arc is very soft and smooth. Chamfers usually have a straight line transition at a certain angle such as 45 degrees or 65 degrees. Chamfers have a clear direction and a clear bevel turning point between two surfaces.

Mechanical Function

They are both added to reduce stress concentration and improve load-bearing capacity on sharp corners. However, their effect can be varied. Chamfer has a higher stress concentration because it cannot effectively distribute the stress over a broader surface compared to fillets.

Coating

Fillets are easier to be coated than chamfers. This is because fillets blend gently and tangentially with adjacent faces, allowing the part to adhere to a thicker, more even coating than chamfered edges.

Hole or Pin

Whether it is a screw hole, locating hole, or locating pin, chamfering the edge of the hole or pin is a better choice.

Process

Chamfer is relatively simple to get and can be achieved through cutting, grinding, and other conventional processes. Compared with chamfer, fillet is more complicated and requires special tools or casting, molding, and other processes. Some high-precision fillets are usually processed by CNC machining to ensure dimensional accuracy and surface quality.

Cost

Fillets require more complex machining operations and special tools, which increases the overall machining time, so the cost of fillets is often higher. Processing a chamfer is relatively simple and usually only requires conventional cutting or grinding. The same tool can even produce chamfers of different sizes, so the cost of a chamfer is lower.

When to Use Them?

When deciding whether to choose chamfer or fillet, consider the following factors:

Function requirements. Fillets should be considered first when increased strength and durability are critical needs. Chamfers, on the other hand, are a superior option if ease of assembly is a top priority.

Safety purpose. Fillets are more suited for parts that will come into contact with the human body. Because the intersection of the two surfaces in the component forms an arc, it is safer.

Rust resistance. As defined, fillets are the arcs that form the transition between two faces. This arc facilitates the retention of water and pollutants, making it more prone to rusting. In contrast, chimneys are angled slopes that allow water and pollutants.

Processing cost. Chamfers are cheaper than fillets since the former can be produced through simple tools in one motion. If fillet features are not indispensable, Chamfers are the cost-effective option.

After reading the above article, I believe you should have a clear understanding of what fillets and chamfers are. You can use both for different purposes according to your needs. However, choosing the appropriate one for your design is a critical decision when designing a part. The right choice can make these design features more efficient, cost-saving, and last longer.