CNC machining programming is the process of creating detailed instructions that guide a machine to perform precise CNC machining operations. These instructions are written in a language known as G-code, the G-code tells the machine how to move, at what speed, and along which path. In this article, we will discuss what CNC machining programming is, how it works, methods and code examples.

What is CNC Programming?

CNC programming is the process that uses computer software to turn geometrical information into codes and instructions to guide cutting machines’ movements. These codes and instructions precisely control the cutting tool’s path and cutting parameters to remove the extra materials orderly to shape the workpiece into the desired shape.

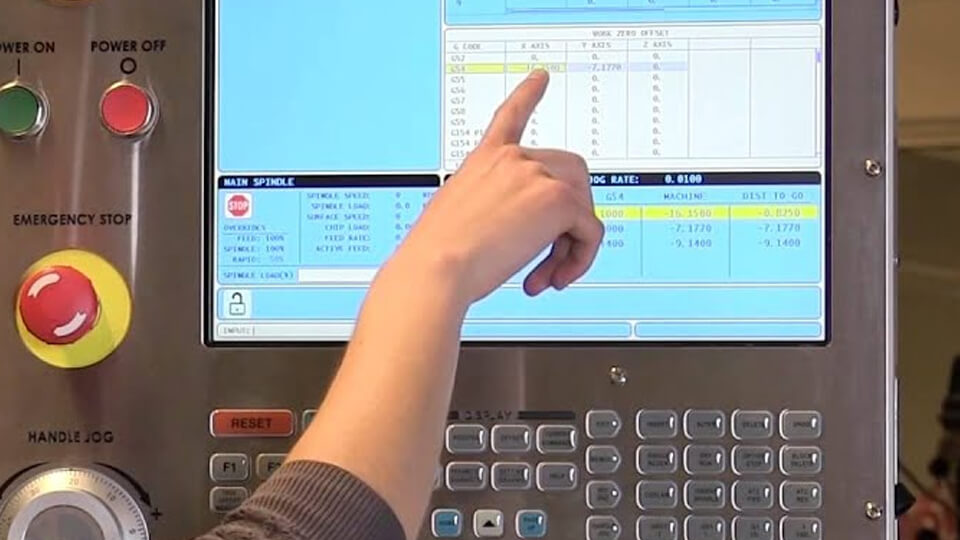

In CNC programming, skilled operators select appropriate cutting tools, cutting parameters and sequences according to the drawings and requirements, and use specialized software to convert them into codes and instructions that can be read by the machines. These codes are input into the control panel of the CNC machine, and the machine will process according to the instructions preloaded.

How Does CNC Programming Work

There are multiple steps involved in converting a design into CNC machine program code. The programmer accesses the required part’s CAD model, uses CAM software to convert it, builds tool paths based on design elements, and produces the CNC program, or G-code. After entering this G-code into the CNC machine, the programmer hits the cycle start button to start producing the part.

Different Types of Programming

There are 3 types of CNC programming existing in the CNC machining process – manual, CAM and conversational. Each has its distinguished properties.

Manual CNC Programming

Manual Programming refers to A programmer directly entering the codes and instructions in the control console relying on his rich knowledge. it is a good idea to machine simple parts.

Conversational CNC Programming

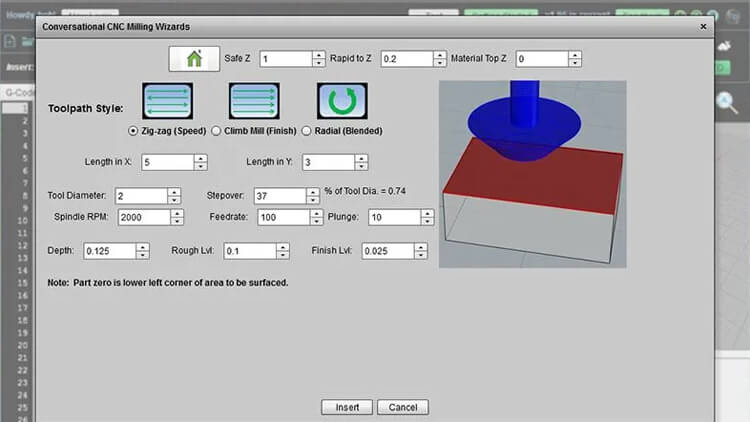

Conversational programming allows you to communicate with the system in natural language, just like you are talking to a person. The programming system will understand your instructions and generate corresponding code. Like manual programming, it is suitable for parts with simple geometry.

CAM CNC Programming

CAM means”Computer-aided manufacturing”, CAM programming leverages CAM software to convert CAD design into CNC programming languages. it is ideal for both simple and complicated parts.

Comparison of 3 Programming Methods

| Method | Manual Programming | Conversational Programming | CAM Programming |

| Ease of Use | Difficult. Requires significant expertise and experience. | Relatively easy. Allows for natural language interaction | Easy. Requires some learning curve but offers a wide range of features |

| Programming Speed | Slow. Each step needs to be manually entered and adjusted | Quicker than manual as instructions can be given in a more intuitive way | Faster for complex parts. |

| Flexibility | Low flexibility | Moderate flexibility | High flexibility |

| Accuracy | Prone to human errors | More accurate as it follows specific instructions | Most accurate |

| Applicability | Simple tasks | Simple tasks | both simple and complex parts. |

CNC Programming Code Examples

CNC programming codes can be broadly classified into several types. They play a unique role in CNC machining and the operators usually use a combination of different codes to process the part.

G-code: These codes control the movement of the cutting tool in terms of linear, circular, helical, and other geometric paths.

F-codes: These codes specify the feed rate at which the tool moves during machining

S-codes: These codes control the speed of the spindle, such as surface speed, spindle speed, incremental speed, etc.

T-codes: These codes are used to select a specific tool from the tool magazine.

M-codes: These codes perform various auxiliary functions like turning on/off coolant, spindle start/stop, and tool change.

N-codes: These codes represent sequence or line numbers used to organize and identify each block of code within a CNC program. Each line or block typically contains a command that controls a specific movement.

Take the following set of codes as examples to demonstrate.

| N10 G90 G17 G21 | Set absolute programming, XY plane selection, millimeter units |

| N20 G00 X0 Y0 | Rapid move to the origin (X0, Y0) |

| N30 G43 H1 Z5 | Tool length offset applied to tool 1, move Z to 5mm above the part |

| N40 M03 S1200 | Rapid move back to the origin |

| N50 G01 Z-10 F200 | Feed move down to Z = -10mm with 200mm/min feedrate |

| N60 G01 X50 Y50 | Linear move to X50, Y50 at the current feedrate |

| N70 G02 X100 Y0 I25 J-25 | Arc move in clockwise direction to X100, Y0 with center at (I25, J-25) |

| N80 G01 X150 Y0 | Linear move to X150, Y0 |

| N90 G00 Z5 | Rapid move up to Z = 5mm |

| N100 M05 | Spindle stop |

| N110 G00 X0 Y0 | Rapid move back to the origin |

| N120 M30 | Program end and reset |

Recommendable Paid CAM Software

Computer-aided manufacturing (CAM) software converts CAD models into programs that can be read by machines. There are many CAM software in the market, we highly recommend the following paid software for their powerful function and user base.

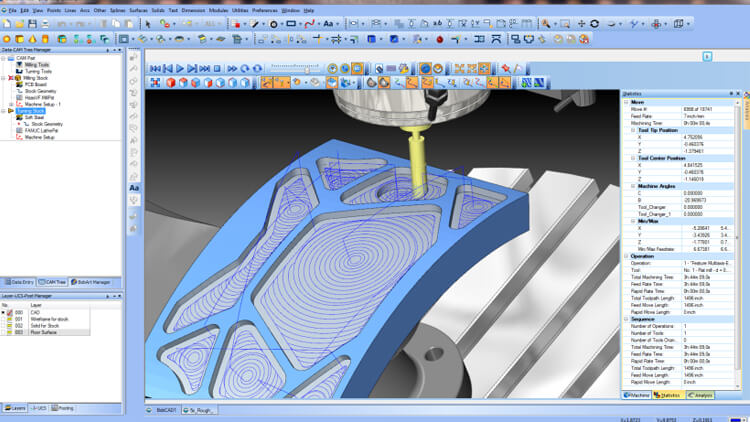

MaserCAM

Mastercam is a PC-based CAD/CAM application created by CNC Software Inc. It combines a variety of functions, including 2D sketching, 3D solid modeling, surface design, voxel stitching, CNC programming, tool path simulation, and realistic simulation.

Mastercam has strong surface roughing and surface finishing functions. There are many options for surface finishing, that can meet the surface processing requirements of complex parts and have multi-axis processing functions. Because of its inexpensive cost and outstanding performance, it has become the preferred CNC programming software in a variety of sectors.

SolideCAM

SolidCAM is tightly integrated with SOLIDWORKS and provides multi-axis milling, turning, and EDM. Its iMachining technology is a standout feature, as it can automatically design the optimal machining route based on the material and tool, significantly reducing machining time and extending tool life.

Fusion 360

Fusion 360, is a cloud-based program that blends CAD and CAM to enable industrial operations ranging from simple 2D milling to complicated 5-axis machining. Fusion 360 effortlessly connects with the design module and facilitates team collaboration. Its features include a low price and a wide range of functionalities that are appropriate for both beginners and professionals.

Free CAM Softwares

If you are new to CNC machining or just looking for free CAM software for individual use. the following options may be suitable for you.

Fusion 360 for Personal Use

Fusion 360 provides a free personal version that is appropriate for small, noncommercial applications. It combines CAD and CAM capabilities to enable simple to complicated manufacturing jobs such as 2.5D, 3D, and multi-axis machining. Fusion 360 Personal Edition is appropriate for novices, enthusiasts, and small studios.

Download it: https://www.autodesk.com/products/fusion-360/personal

FreeCAD

FreeCAD is an open source 3D modeling software that supports CAM processing functions. Its Path Workbench allows users to create tool paths, suitable for CNC processing tasks. FreeCAD’s functions are relatively simple and suitable for the manufacturing needs of individuals and small projects.

Download it: https://www.freecad.org/downloads.php

Carbide Create

Carbide Create is a free 2D and 3D CAM software with relatively basic functions, an intuitive interface and a simple workflow. It is a good choice for small projects and entry-level users.

Download it: https://carbide3d.com/carbidecreate/download/

Tips to Improve CNC Programming Skills

To be a skilled CNC machining programmer, it’s crucial to continually upgrade your programming skills and knowledge.

Make full of CNC Programming Courses

Making the most of the many free courses available is useful. Popular courses like “CNC Programming with G Code for Beginners” by Marc Cronin and “Fusion 360 for Beginners” by Lars Christensen are available on platforms like Udemy and YouTube. These courses offer free lessons from fundamental G-code writing to sophisticated toolpath development.

Apprenticeships

One thorough approach to learning CNC programming is most likely through an apprenticeship. These courses usually combine classroom instruction with practical work and are frequently funded by businesses, labor unions, or collaborative labor-management organizations. The ideal place to look for an apprenticeship is through job search engines like Indeed or LinkedIn, as they are regarded as full-time positions. Additionally, a list of apprenticeship programs is provided by the Department of Labor.

Practice More

Find some real projects or cases to practice programming. You can start with simple parts and gradually increase the difficulty. Using a CNC machine simulator for practice is a good choice. The simulator can simulate the operation and processing of the machine, allowing you to perform programming debugging without actually using the machine, reducing costs and risks. During the practice, record the problems encountered and the solutions. These experiences will help you avoid similar mistakes in future programming.