When shopping for stainless steel tableware, you’ll often see labels like “304 stainless steel.” Some sellers claim, “304 is food-grade stainless steel,” while others say, “316 is better than 304.” So, what do these confusing numbers mean? And what do they have to do with being food-grade?

What is Food Grade Stainless Steel?

Food-grade stainless steel is a type of stainless steel designed for food applications. It has the basic properties of stainless steel, such as corrosion resistance and rust prevention, while also ensuring that no harmful substances are released when it contact with food. Food-grade stainless steel offers multiple advantages:

- Corrosion resistant: Food-grade stainless steel resists rust and corrosion, even in acidic or alkaline environments over long periods.

- Heat resistant: It can handle high temperatures without melting or losing shape.

- Hygienic: It won’t contaminate food or affect its quality and safety.

- Easy to work with: This steel is simple to cut, weld, bend, and shape during processing.

The following discusses the international standards and regulations for food-grade stainless steel that cover specific requirements and testing methods:

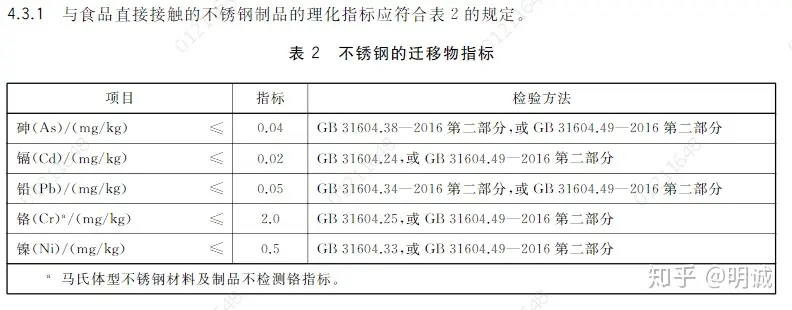

Chinese Standard: GB4806.9-2016

China’s GB4806.9-2016 standard covers food-grade stainless steel, including austenitic, ferritic, and other types. Martensitic stainless steel is allowed for tableware and equipment—the standard tests for harmful element migration. A 4% acetic acid solution, mimicking acidic food, boils in a steel container for 30 minutes, then sits at room temperature for 24 hours. Heavy metals like arsenic, cadmium, lead, chromium, and nickel are measured. Levels must stay below limits: lead at 0.05 mg/kg, nickel at 0.5 mg/kg. This controls chronic toxicity risks to health.

U.S. Standards: FDA and NSF

The FDA and NSF govern food-grade stainless steel in the U.S. FDA rules require at least 16% chromium to form a protective oxide layer against rust and corrosion. NSF demands a smooth surface, with an Ra value of 0.8 micrometers or less, to limit bacteria. Studies show stainless steel is inert, but chromium and nickel can leach into food. This depends on steel type, cooking heat, time, and food acidity. A meal releases under 45 micrograms of chromium, far below the 50-200 micrograms daily safe intake for adults.

European Standards

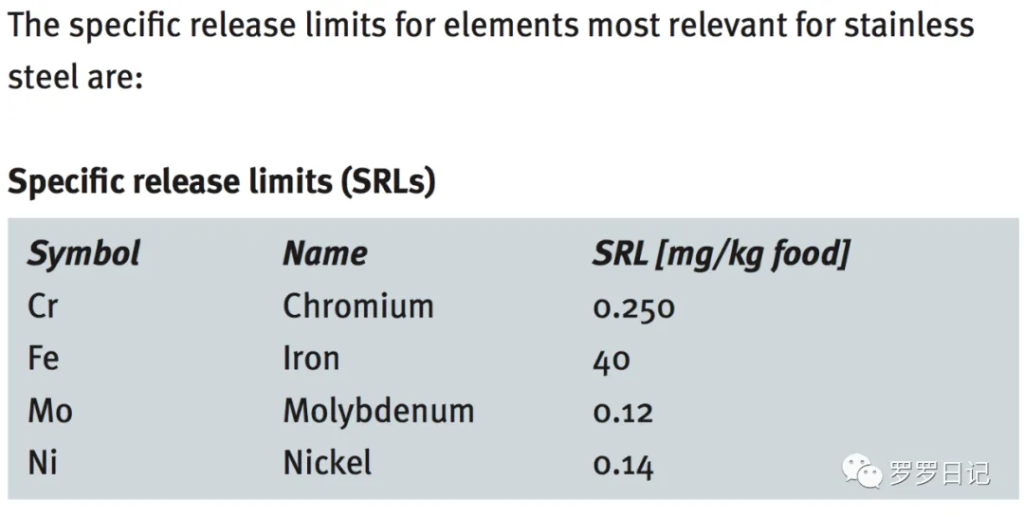

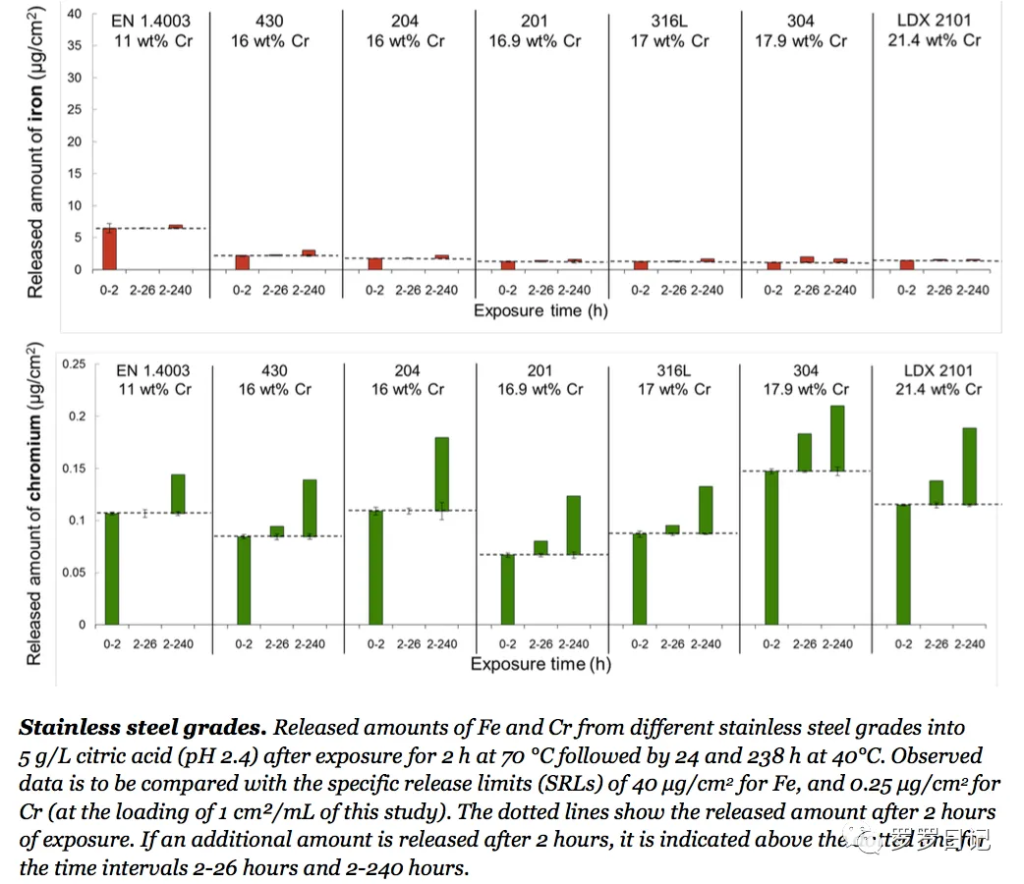

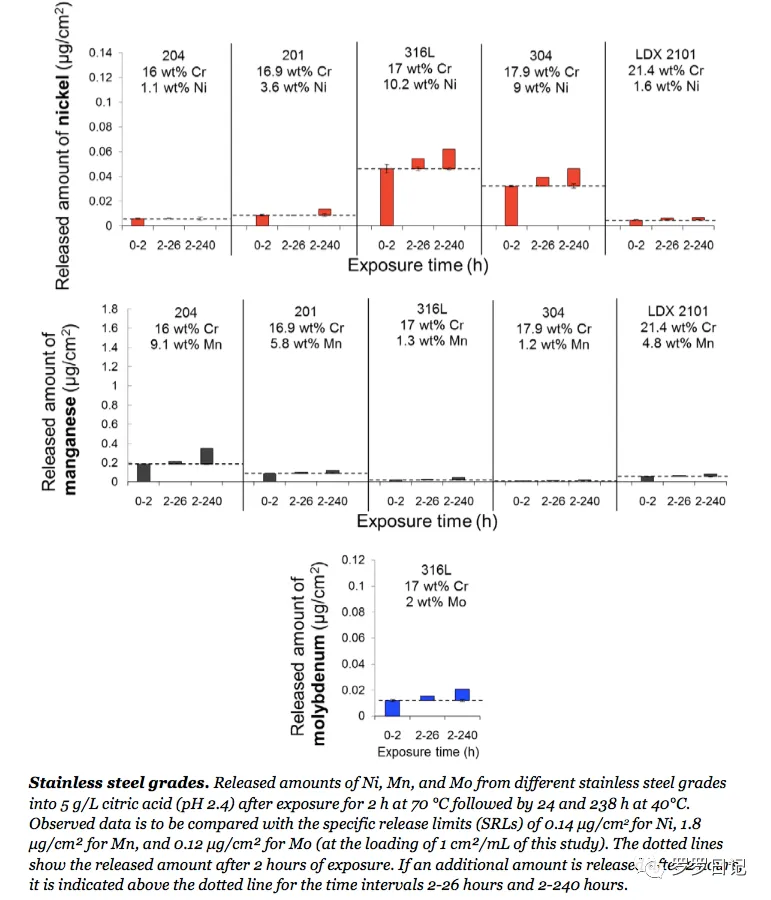

Europe has no set chromium standard but requires metal release tests. The European Food Safety Authority uses a 5 g/L citric acid solution at pH 2.4. Steel is exposed at 70°C for 2 hours, then rests at 40°C for 24 or 238 hours. Iron, chromium, nickel, and manganese levels are checked. Limits include nickel at 0.1 mg/kg and chromium at 0.25 mg/kg. This mimics acidic food contact to ensure safety. France sets a minimum of 13% chromium.

Common Grades of Food-grade Stainless Steel

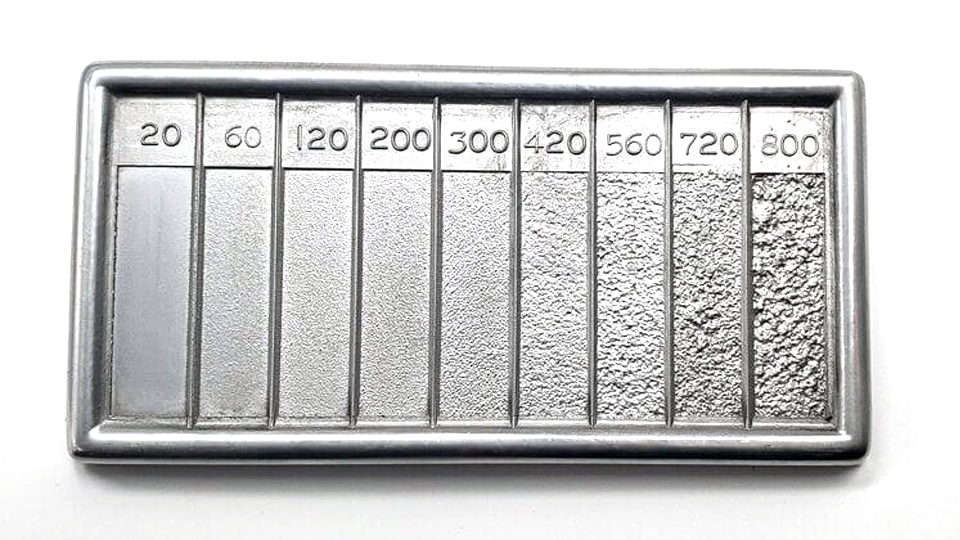

Stainless steel is categorized into various series and grades based on its composition and microstructure. The 300- and 400-series are commonly used in the food industry.

304 Stainless Steel

304 stainless steel is the most common type used in cookware. In the cutlery grading system, it’s often labeled as 18/8 stainless steel. The first number stands for 18% chromium, and the second means 8% nickel. These elements give the steel its strength, shine, and resistance to rust.

316 Stainless Steel

316 stainless steel contains about 16–18% chromium, 10–14% nickel, and 2% molybdenum. In the cutlery grading system, it’s called 18/10 stainless steel, meaning it has 18% chromium and 10% nickel. It’s less common than 304 stainless steel and is seen as a premium option due to its excellent corrosion resistance. It’s called surgical-grade stainless steel since it’s widely used in medical implants. However, 316 stainless steel is expensive, so it’s rare in cookware.

Is 316 better than 304? In terms of corrosion resistance—yes. But for everyday cooking, high-quality 304 stainless steel is usually enough. Unless you’re cooking acidic foods, you won’t need 316.

430 Stainless Steel

430 stainless steel is magnetic and contains no significant amount of nickel. In the cutlery grading system, it’s known as 18/0 stainless steel, meaning it has 18% chromium and about 0.75% nickel. Without nickel, 430 is more prone to rust and corrosion than 304 or 316, and it can lose its shine over time.

440 Stainless Steel

440 and 440C stainless steels are also used in food-grade applications. They are known for their high hardness, which comes from heat treatment. These grades are common in kitchen knives because of their strength, sharp edge, and wear resistance. However, they are more prone to rust than 304 or 316, so they are not ideal for cutlery or serving utensils.

Is Food Grade Stainless Steel Equal to 304 or 316?

Labels like “food-grade,” “aircraft-grade,” or “medical-grade” refer to specific industrial standards. Just knowing the steel grades isn’t enough to claim it meets those grades. For instance, 304 stainless steel means the material meets the general properties defined in national standards. But only 304 that complies with the standard, such as GB 4806.9-2016—China’s food safety standard for metals in contact with food, can truly be called food-grade stainless steel.