The world of 3D printing services has witnessed unprecedented growth, revolutionizing industries from aerospace to healthcare. Yet, understanding the factors influencing the cost of 3D printing services is vital for making informed decisions and optimizing expenses. In this article, we delve into the key determinants of 3D printing service costs and explore strategies for cost reduction.

Factors Affecting 3D Printing Service Costs

3D printing is rapidly transforming industries and hobbies alike. It’s a powerful tool, but cost considerations are crucial. Whether you’re a hobbyist or a business, understanding the factors affecting 3D printing costs is essential. In this discussion, we’ll explore these key factors, including technology choices, material selection, batch printing, part complexity, and post-processing.

Material Selection

The type of material used in 3D printing significantly influences costs. Materials vary widely in price and can range from affordable plastics like PLA to high-performance thermoplastics or metals. To minimize costs, select a material that meets your project’s functional and aesthetic requirements without breaking the bank. Below, I’ve provided a general overview of the unit prices for several common 3D printing materials:

More expensive 3D printing materials typically can offer specific advantages like enhanced strength, durability, or unique properties. However, a well-printed model can also be printed using standard materials that are significantly cheaper. whether they are better depends on your project’s specific requirements and budget. It’s crucial to select materials that match your project’s needs without incurring unnecessary costs.

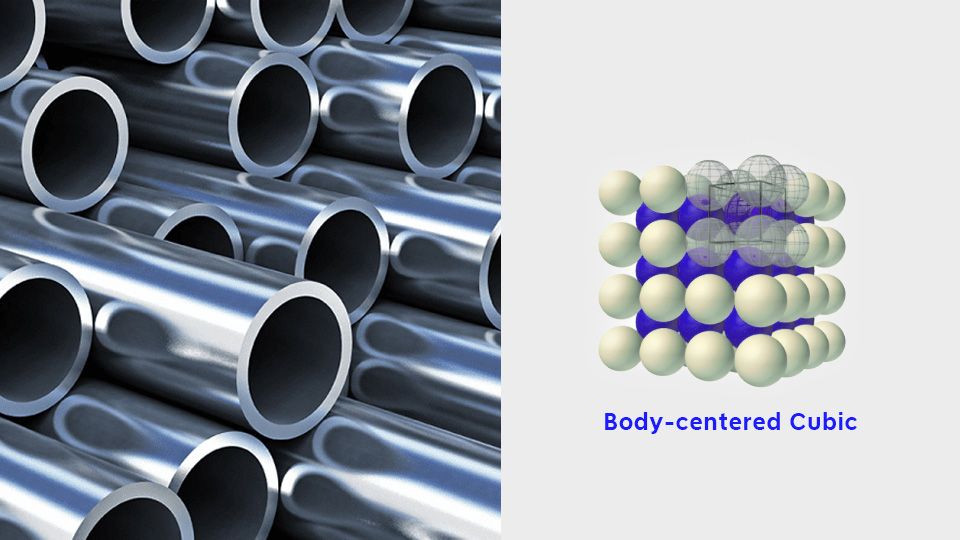

Printing Technology

The choice of 3D printing technology plays a pivotal role. When comparing 3D printing technologies, two notable ones are Fused Deposition Modeling (FDM) and Stereolithography (SLA). FDM is cost-effective, using thermoplastic filaments for part building. SLA offers high accuracy and versatility but comes at a higher cost. Other options like SLS, SLM, and DMLS are pricier due to their rarity and ability to work with metals. Select the technology that aligns with your project’s specifications and quality expectations to optimize costs.

Post-processing

Post-processing techniques like polishing and electroplating can enhance the functionality and aesthetics of 3D-printed parts. However, it’s essential to note that the utilization of these processes comes at an additional cost to the overall 3D printing service. The cost varies depending on the specific post-processing method employed. Below, we’ll explore some common post-processing techniques and their impact on the overall service cost.

1. Support Structure Removal

After 3D printing, support structures that aid in the printing process need to be removed. This is often done manually. The costs are usually minimal and may be included in the 3D printing service.

2. Sanding and Smoothing

Sanding and smoothing techniques are used to eliminate layer lines and imperfections on 3D-printed surfaces, resulting in a smoother finish. Costs vary depending on the complexity of the part but typically range from low to moderate.

3. Painting and Finishing

Painting and finishing post-processing involves applying paints, coatings, or finishes to enhance the appearance, color, and surface texture of the 3D-printed object. Costs depend on complexity, the number of colors, and the quality of paint used. Ranges from a few dollars for basic finishes to higher costs for intricate or multilayered painting.

4. Mechanical Polishing

Mechanical polishing techniques, such as tumbling or abrasive finishing, are used to achieve a smooth and shiny surface on 3D-printed parts. Costs depend on part size, complexity, and the duration of the polishing process. Typically ranges from low to moderate.

5. Electroplating

Electroplating involves depositing a layer of metal onto the 3D-printed object’s surface, enhancing its aesthetics, or adding functional properties, such as electrical conductivity. It is used to achieve metallic finishes and improve durability. The cost of electroplating varies based on factors such as the type of metal used (e.g., gold, silver, chrome), the size and complexity of the part, and the desired thickness of the plating. Costs can range from moderate to high, with precious metals being more expensive.

Part Size and Complexity

The size and intricacy of your 3D-printed part significantly impact costs. Large and intricate designs consume more material and time, often requiring additional post-processing steps, resulting in higher expenses. Simplifying your designs or breaking complex parts into smaller components can reduce costs.

Batch Printing

The quantity of parts ordered is another factor influencing 3D printing costs. Ordering a single prototype may cost more per unit than ordering a larger batch. Batch printing optimizes machine time and material usage, resulting in cost savings.

Strategies for Reducing 3D Printing Service Costs.

Set-up and Operation Cost

Setup costs, also known as initial or capital costs, involve the expenses associated with establishing a 3D printing environment. These costs are primarily one-time or upfront expenditures required to get started with 3D printing. Setup costs typically include the purchase of 3D printers and any necessary accessories, such as print beds, extruders, or post-processing tools. It may also cover installation and setup charges for the equipment.

Operation costs are the ongoing, recurring expenses incurred during the regular use of 3D printing equipment and the production of 3D-printed objects. These costs include the day-to-day expenses of running and maintaining a 3D printing operation. Operation costs consist of various elements, such as material costs (filaments or resins), labor costs (for design, printing, and post-processing), energy costs (electricity to run the equipment), space costs (rental or utility expenses for the workspace), and other recurring expenses related to the production process.

How to Reduce the cost of 3D printing

Technologies and Materials

To reduce 3D printing costs in terms of technologies and materials, select the most appropriate technology for your specific project needs and budget. Fused Deposition Modeling (FDM) and Stereolithography (SLA) are often more cost-effective than high-end alternatives. When it comes to materials, optimize efficiency by minimizing supports and infill density. Select materials that offer a balance between cost and quality. Additionally, explore the potential for material recycling, and repurposing excess or failed prints to reduce material expenses.

Batch Printing and Part Complexity

For cost savings through batch printing, maximize your printer’s build volume by grouping multiple objects into a single print job. Efficiently arrange objects within the build volume to minimize material waste and shorten printing time.

Reducing 3D printing costs by optimizing part complexity involves simplifying the design of 3D models. Intricate and complex designs can increase both printing time and material usage. To lower these costs, consider minimizing unnecessary details and intricate features in your 3D model while maintaining the core functionality.

1. Simplify Designs

Complex designs often demand more material and time. By simplifying the design and minimizing intricate features, you can reduce material consumption and printing time. Fewer complex curves, angles, or intersecting components can lead to significant cost savings.

2. Efficient Supports

Complex parts often necessitate extensive support structures during printing. Analyze the design closely to determine where support structures are truly needed. Using supports judiciously can decrease material waste and simplify post-processing.

3. Infill Optimization

Adjust the infill density within your 3D-printed part. Infill refers to the internal structure, and higher densities enhance strength but increase material usage and printing duration. For parts where maximum strength isn’t crucial, lowering infill density can reduce costs while maintaining structural integrity.

4. Design for Additive Manufacturing (DfAM)

Implement the principles of Design for Additive Manufacturing (DfAM) to create parts tailored for 3D printing. DfAM prioritizes designs that fully exploit the technology’s capabilities, simplifying complex features and focusing on functional requirements.

5. Combine Components

Consider consolidating multiple complex parts into a single assembly whenever possible. Reducing the number of individual components can lower material usage and streamline post-processing, especially assembly and integration tasks.

Post-Processing

Minimizing post-processing costs is achieved through strategic decision-making and efficient techniques. First, design parts that require as little post-processing as possible. By minimizing intricate details and focusing on functional aspects, you can eliminate or simplify time-consuming and costly finishing steps. Standardize your finishing techniques whenever feasible, such as using spray paint for uniform coloration. Instead of opting for high-cost finishing methods like electroplating, consider cost-effective alternatives like surface coatings or traditional paint applications. These strategies reduce post-processing complexity and costs while maintaining the quality and functionality of your 3D-printed objects.

Summary

The article highlights factors affecting 3D printing service costs, including material, technology, post-processing, part complexity, and batch printing. It offers strategies for cost reduction, such as selecting cost-effective materials and technologies, simplifying designs, and minimizing post-processing expenses through efficient techniques and standardization.

To learn more about 3D printing services and select the optimal 3D printing technology and material for your projects, feel free to contact the SogaWorks account representative. SogaWorks offers a wide range of 3D printing services for your custom project needs. Get a free, no-hassle quote with our instant quote system.