What is bending?

Bending is a stamping process that uses pressure to force plastic deformation of materials to form a shape with a certain angle and curvature. Commonly used bends include V-shaped bends, Z-shaped bends and reverse bending.

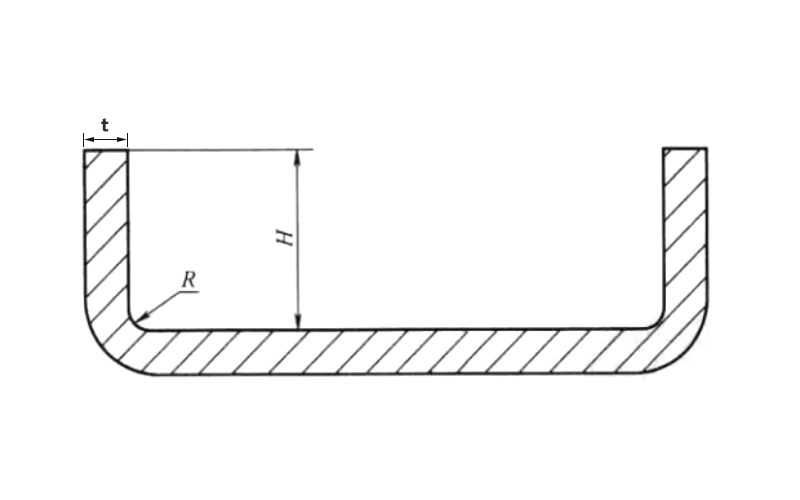

Bending height

The bending height is at least twice the thickness of the sheet metal plus the bending radius, that is, H≥2t+R, as shown in the figure below. If the bending height is too low, the sheet metal will be easily deformed and distorted during bending, making it difficult to obtain the ideal part shape and dimensional accuracy.

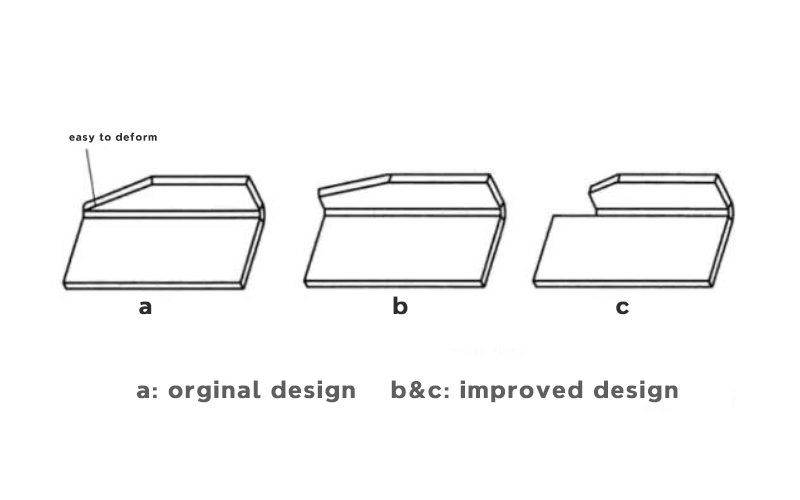

When bending on the hypotenuse, it is easy to cause distortion and deformation of the bending due to the bending height being too small. As shown in the figure below, in the original design, because the bending height on the left side is too small, distortion and deformation easily occur during bending, resulting in low bending quality; when improving the design, it is recommended to increase the bending height on the left side or remove the part with small bend height.

Bending radius

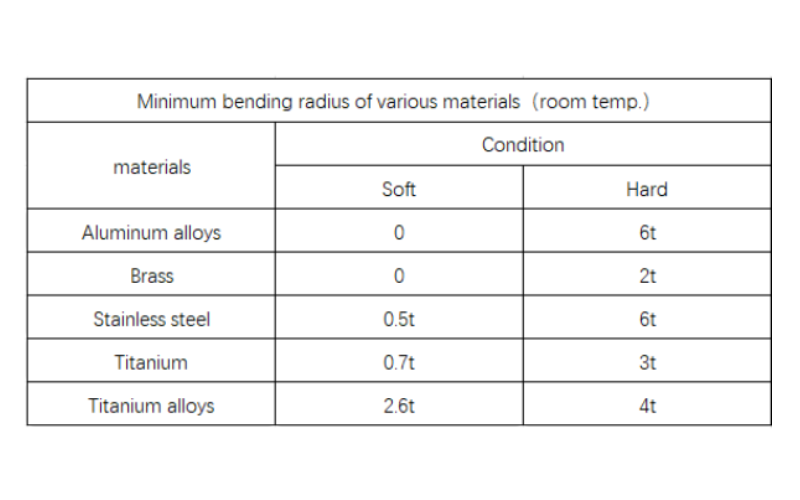

To ensure the bending strength, the sheet metal bending radius should be greater than the minimum bending radius of the material. The minimum bending radii of various common sheet metal materials are shown in the table below, where t is the thickness of the sheet metal.

It does not mean that the larger the sheet metal bending radius, the better. The larger the bending radius, the greater the bending rebound force, and the harder it is to control the bending height and angle. Therefore, the sheet metal bending radius needs to be a reasonable value.

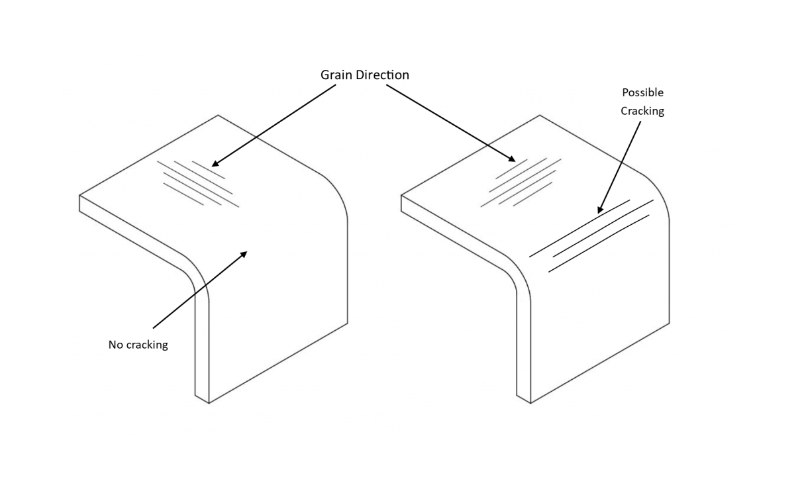

Bending direction

The bending direction of sheet metal should be perpendicular to the fiber direction of the metal material. When the bending direction of the sheet metal is parallel to the fiber direction of the metal material, cracks are likely to occur at the bending point of the sheet metal.

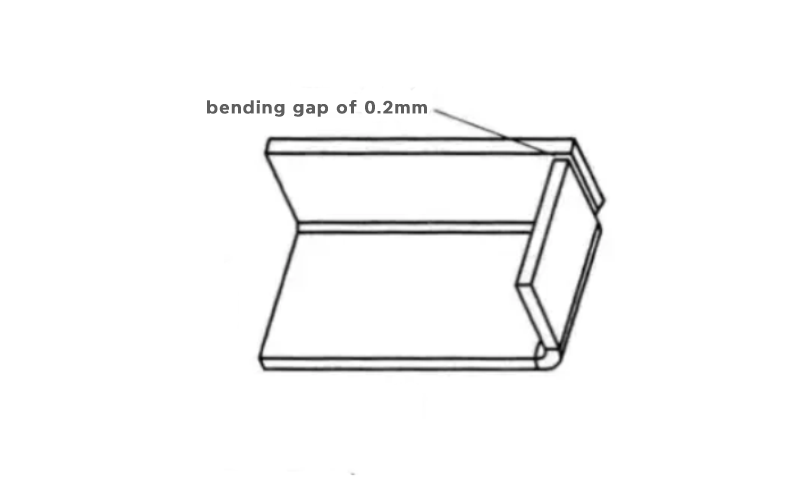

Bending gap

Due to the existence of sheet metal bending tolerances, there needs to be a certain bending gap in the movement direction of sheet metal bending to avoid interference during bending and causing bending failure.

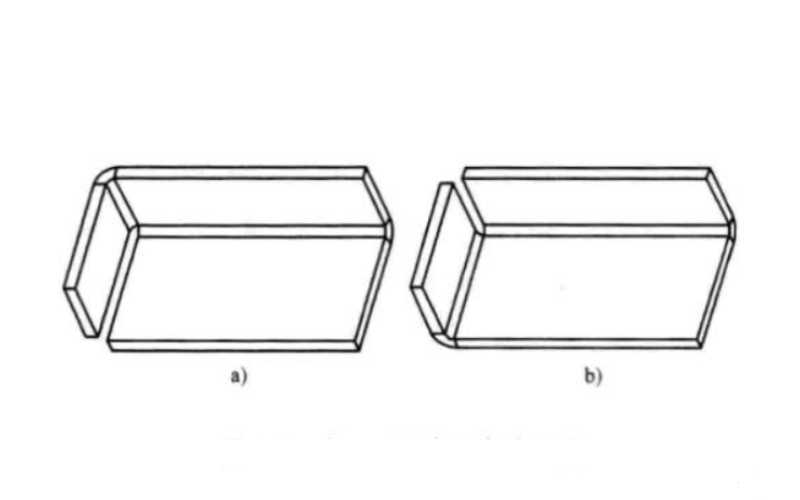

Bending strength

The bending strength needs to be considered when bending sheet metal parts. Long and narrow bending strength is low, and short and wide bending strength is high. Therefore, the bending of sheet metal parts should be attached to the longer side as much as possible.

Avoid complicated bends

The more complex the sheet metal bending process is, the higher the mold cost, and the lower the bending accuracy. Therefore, when the sheet metal parts have complex structures, you can consider splitting the complex bending parts into multiple parts, which will help reduce costs and improve product quality.