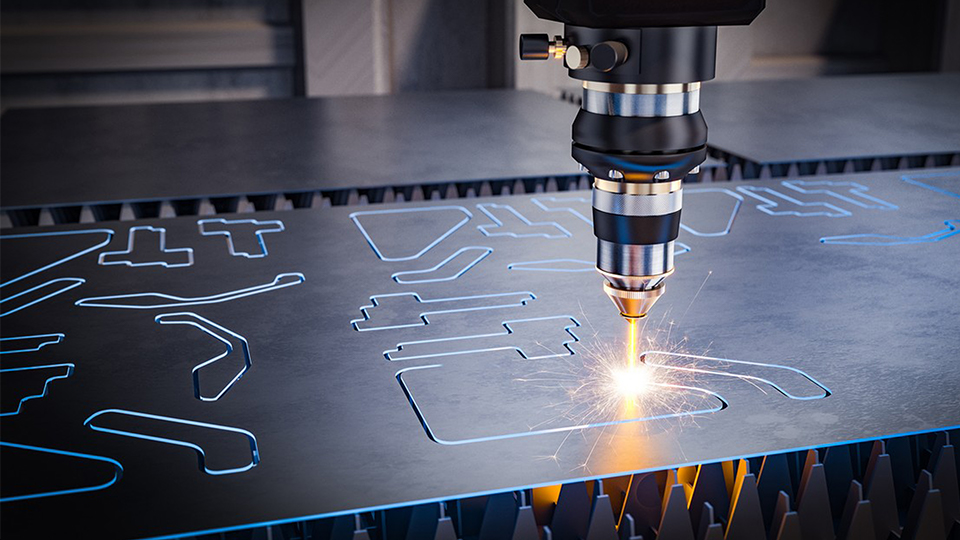

A Welder‘s Guide to Metal Active Gas (MAG) Welding

Metal Active Gas (MAG) welding is a versatile and widely used welding process that combines the benefits of Gas Metal Arc Welding (GMAW) with the use of an active shielding gas. This guide aims to provide a comprehensive overview of MAG welding, covering its fundamental concepts, key knowledge areas, and practical applications. Whether you are