Surface Finish: What is Phosphating Coating?

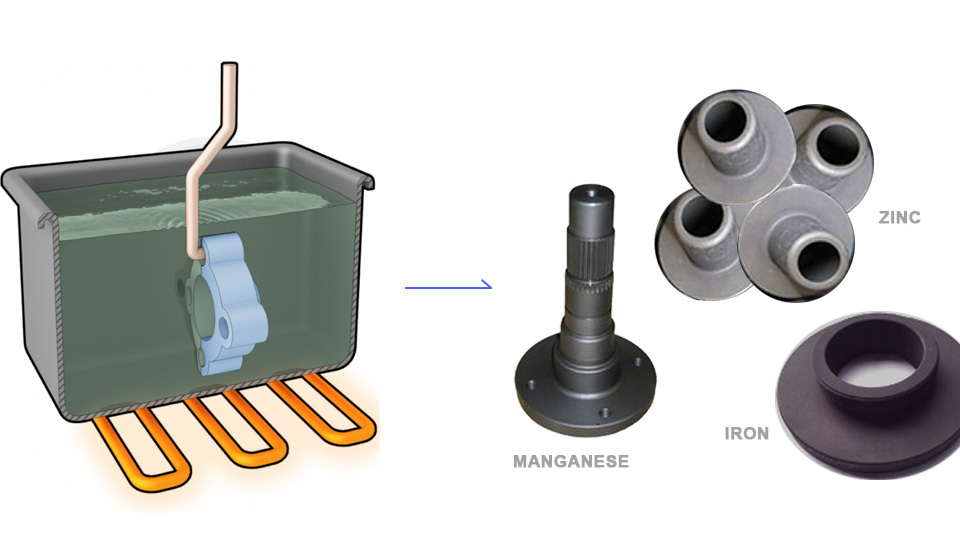

Phosphating is a process that forms a phosphate conversion coating on a metal surface through chemical and electrochemical reactions.

Phosphating is a process that forms a phosphate conversion coating on a metal surface through chemical and electrochemical reactions.

Stainless steel passivation is a surface treatment that enhances the corrosion resistance of stainless steel.

anodizing is a process of deliberately oxidizing metal surfaces by electrochemical means. Titanium anodizing is a specific application of the anodizing process

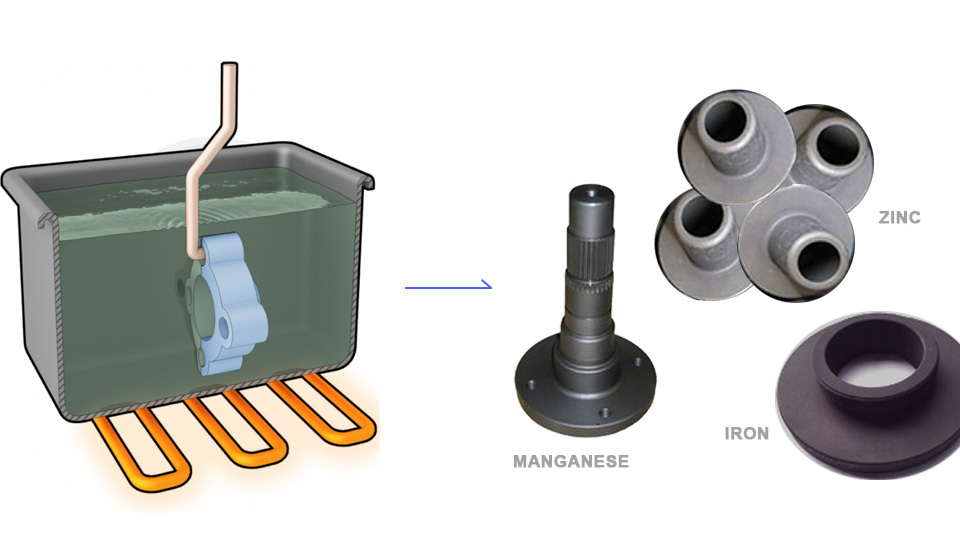

Surface roughness (Ra) is the measure in micrometers of the microscopic peaks and valleys in the surfaces of materials.

andblasting uses compressed air to blast tiny particles at high speeds onto a part’s surface. It is used for cleaning, roughening, removing rust, or stripping paint.

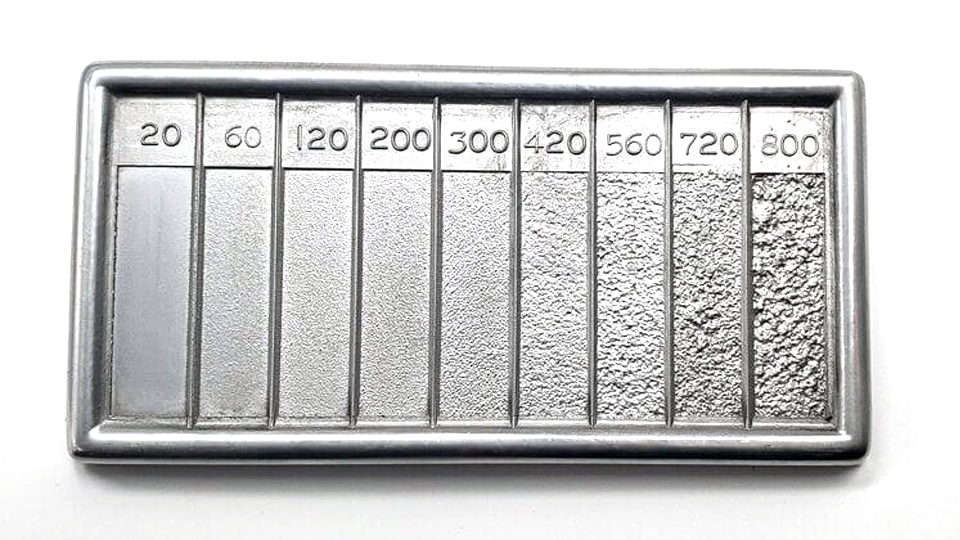

Alodine coating, also known as chromate conversion coating, is a widely used method for enhancing the surface properties of aluminum alloys.

Chrome plating refers to the process of applying a thin layer of chrome onto another metal(like aluminum). This can increase hardness and durability on the surface, prevent corrosion, and even make it easier to clean.

When talking about the finishing of metal parts, two of the common surface treatments discussed will be powder coating and anodizing. Both processes provide critical benefits such as corrosion resistance, durability, and aesthetic appeal, but they achieve these in very different ways.

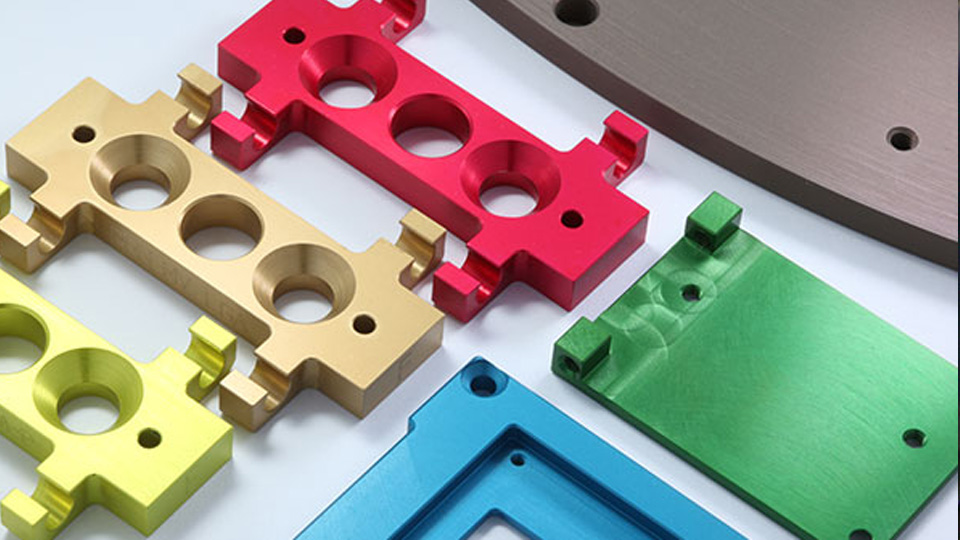

Type II and Type III are two classes of anodizing process. Anodizing is an electrochemical process used to increase the thickness of the natural oxide layer on parts made of metals like aluminum and titanium.

Address:

Room 101-117(the entire 1st floor), 2nd Building,

Tianxin Industrial Zone, Guxing Community, Xi’xiang Street,

Bao’an District, Shenzhen, China. 518126