Welcome to our blog center

You can find tips, basics, guide and more information about manufacturing processes and materials that we have learned from practice here.

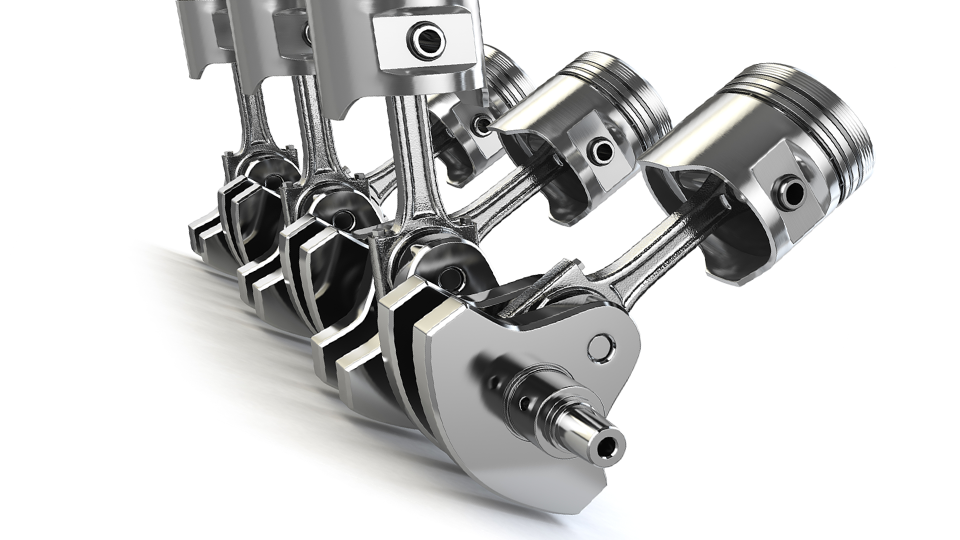

Mastering Piston Machining: Techniques, Materials and Finishes

he piston machining requires high precision and advanced techniques to be able to achieve the most demanding standards in performance. This article will approach the materials used, machining processes involved in the manufacture of pistons.

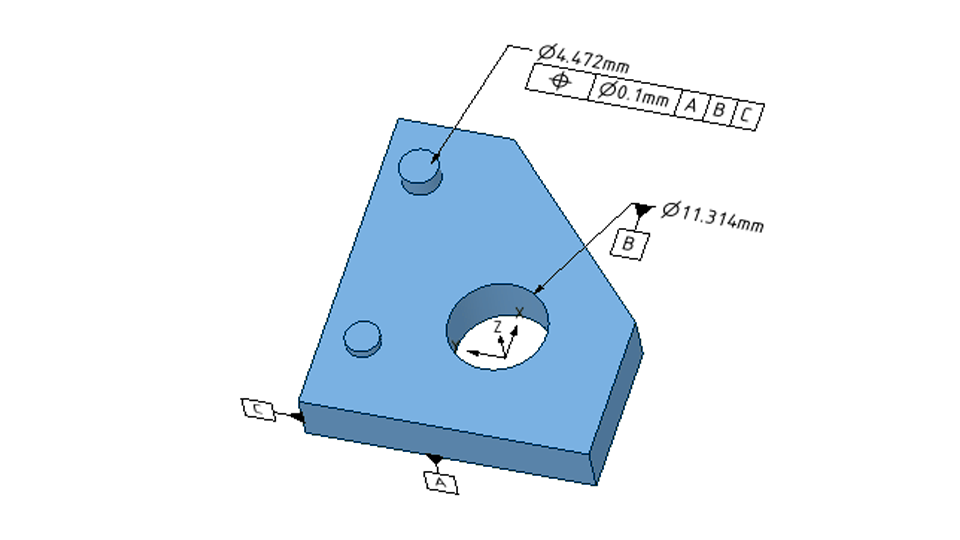

The General CNC Machining Tolerance: ISO 2768-mk

Tolerances are critical to ensure that parts meet design specifications and can be assembled properly. To help you better understand this concept, here is an

What are Engineering Tolerances and How are They Classified?

Engineering tolerances define the acceptable limits of variation of physical dimensions, shapes, or properties of a component. These tolerances ensure that parts fit and function properly in an assembly and that the final product meets the specified requirements.

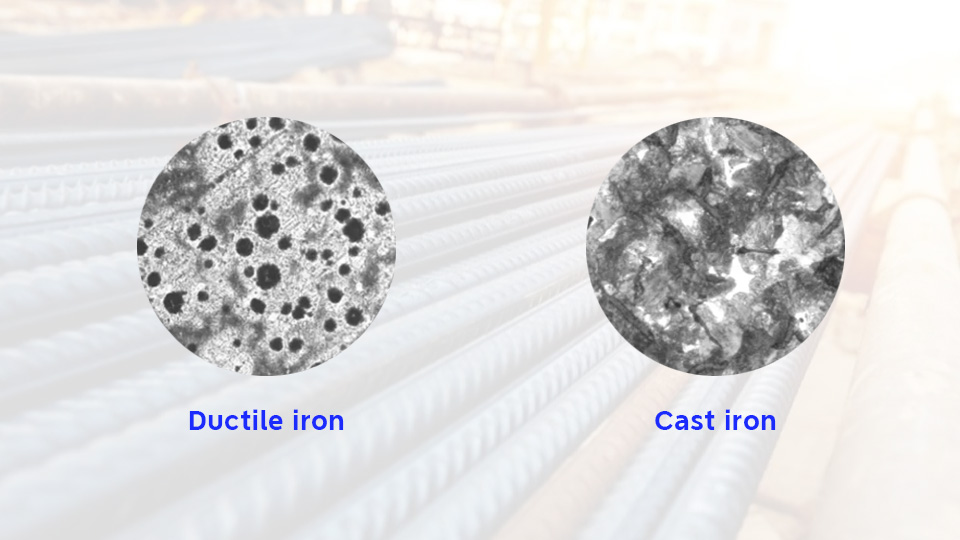

Gray or Ductile Iron? Cast Iron Types Compared for Industrial Use

The term “cast iron” is the generic name for iron-carbon alloys containing more than 2% carbon. The subclasses of cast iron are numerous, some of them are gray iron and ductile iron.

How to Chrome Plate Aluminum and its Alloys

Chrome plating refers to the process of applying a thin layer of chrome onto another metal(like aluminum). This can increase hardness and durability on the surface, prevent corrosion, and even make it easier to clean.

7075 Aluminum: Properties, Benefits, and Uses

Aluminum 7075 is a high-strength, heat-treatable alloy, popular for its excellent mechanical properties and strength-to-weight ratio. This alloy consists of a major composition of aluminum, zinc, and small amounts of magnesium and copper.

Finishing Showdown: Anodizing vs Powder Coating

When talking about the finishing of metal parts, two of the common surface treatments discussed will be powder coating and anodizing. Both processes provide critical benefits such as corrosion resistance, durability, and aesthetic appeal, but they achieve these in very different ways.

Anodizing Class Comparison: Type II vs Type III

Type II and Type III are two classes of anodizing process. Anodizing is an electrochemical process used to increase the thickness of the natural oxide layer on parts made of metals like aluminum and titanium.

SIGN UP FOR US!

Enter your email address to subscribe to our newsletter!

On-demand Manufacturing Services

1 to 1000+ pcs metal or plastic parts, global delivery as fast as 7 days.