Welcome to our blog center

You can find tips, basics, guide and more information about manufacturing processes and materials that we have learned from practice here.

How to Chrome Plate Aluminum and its Alloys

Chrome plating refers to the process of applying a thin layer of chrome onto another metal(like aluminum). This can increase hardness and durability on the surface, prevent corrosion, and even make it easier to clean.

7075 Aluminum: Properties, Benefits, and Uses

Aluminum 7075 is a high-strength, heat-treatable alloy, popular for its excellent mechanical properties and strength-to-weight ratio. This alloy consists of a major composition of aluminum, zinc, and small amounts of magnesium and copper.

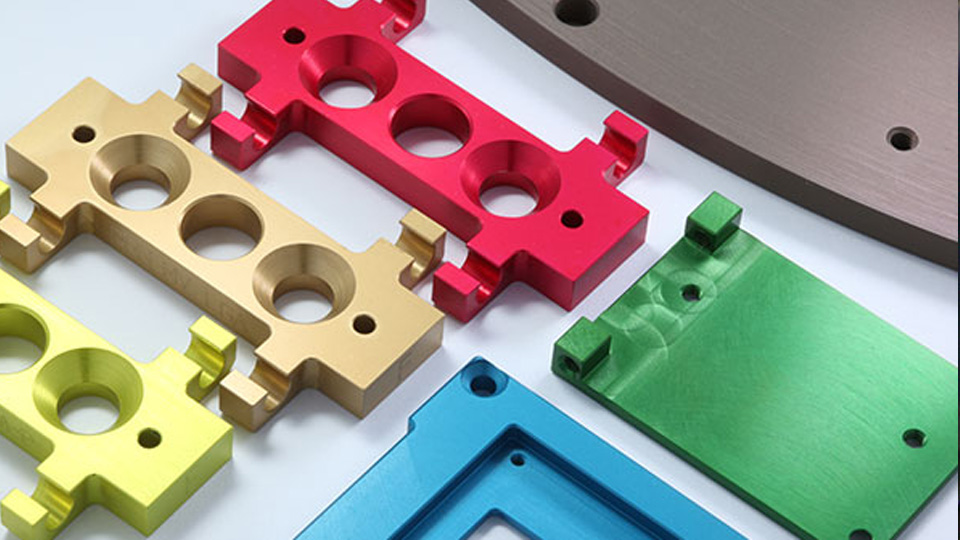

Finishing Showdown: Anodizing vs Powder Coating

When talking about the finishing of metal parts, two of the common surface treatments discussed will be powder coating and anodizing. Both processes provide critical benefits such as corrosion resistance, durability, and aesthetic appeal, but they achieve these in very different ways.

Anodizing Class Comparison: Type II vs Type III

Type II and Type III are two classes of anodizing process. Anodizing is an electrochemical process used to increase the thickness of the natural oxide layer on parts made of metals like aluminum and titanium.

5052 vs 6061 Aluminum: Complete Alloy Comparison

5052 and 6061 aluminum are two commonly used aluminum alloys with unique strengths. This article will examine the key differences in properties, cost, and applications between 5052 and 6061.

SK5 Steel Alloys: Properties and Applications

SK5 steel is rated as one of the best types of high-carbon steel. It is highly regarded by professionals and hobbyists alike for its high hardness and great resistance to wear, a feature that is quite vital in the manufacture of tools for cutting in any industry and also in the crafting of durable blades.

Different Types of Iron: Definition and Properties

Iron is used in many ways. It’s in buildings, infrastructure, vehicles, and equipment. The types of iron are diverse and have special properties. Knowing the different types of iron, like pig iron, wrought iron, and cast iron, helps us choose wisely. This article will explore the types of irons and their properties.

Brass vs. Stainless Steel: Key Comparisons for Material Selection

The material chosen can influence the performance, lifespan, and efficiency of the final parts. Two metals, brass and stainless steel, have unique characteristics and different applications. This article will compare brass vs. stainless steel concerning several important attributes.

SIGN UP FOR US!

Enter your email address to subscribe to our newsletter!

On-demand Manufacturing Services

1 to 1000+ pcs metal or plastic parts, global delivery as fast as 7 days.