Online Custom Laser Cutting Service

High-quality laser cut parts for rapid prototyping and production. Free laser cutting quote with DFM review within 1 day. Lead time as fast as 3 days!

Start A Laser Cutting Quote

STEP I STP I SLDPRT I PRT I IPT I DWG I PDF I DXF I ZIP I RAR

All drawings are secure and confidential.

Types of Laser Cutter

Our laser cutting facility is fully equipped with the latest machinery and technology, enabling us to process a variety of materials, including metals, plastics, and wood, with high precision and at fast speeds. Whether it is custom prototypes or large production runs, our advanced equipment ensures quality and unmatched efficiency.

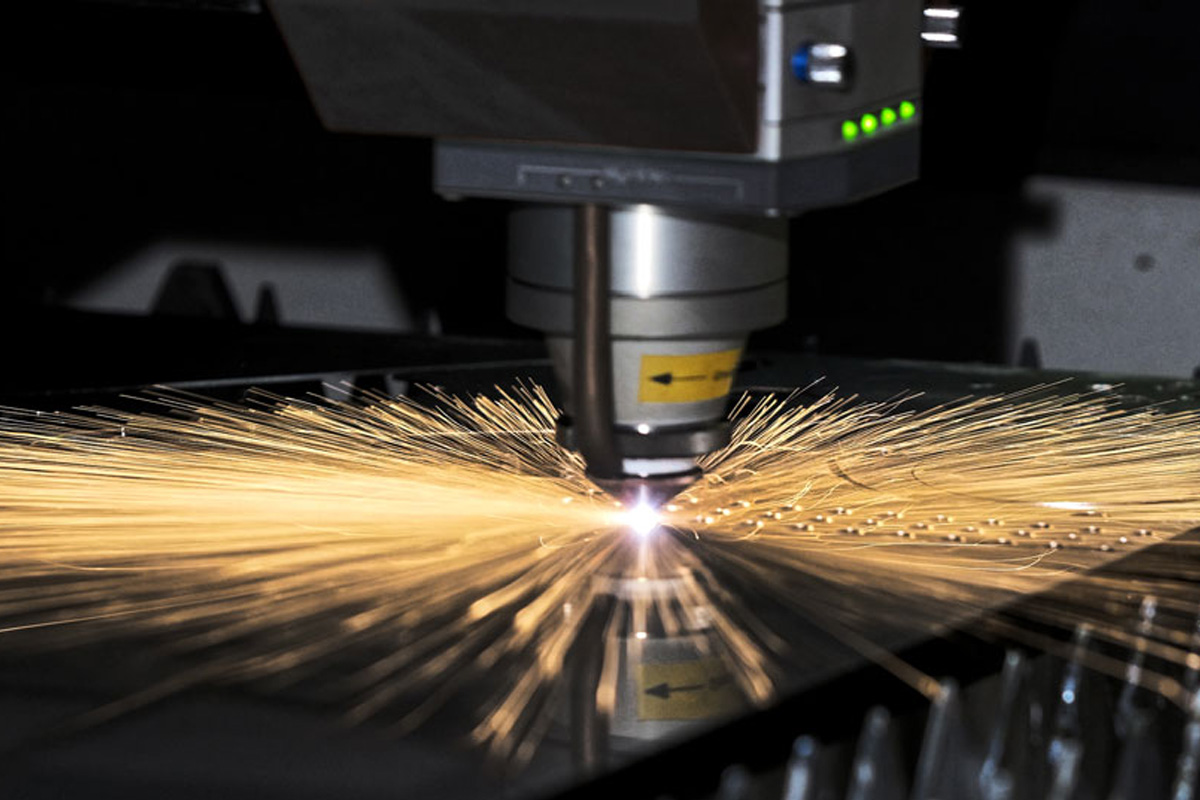

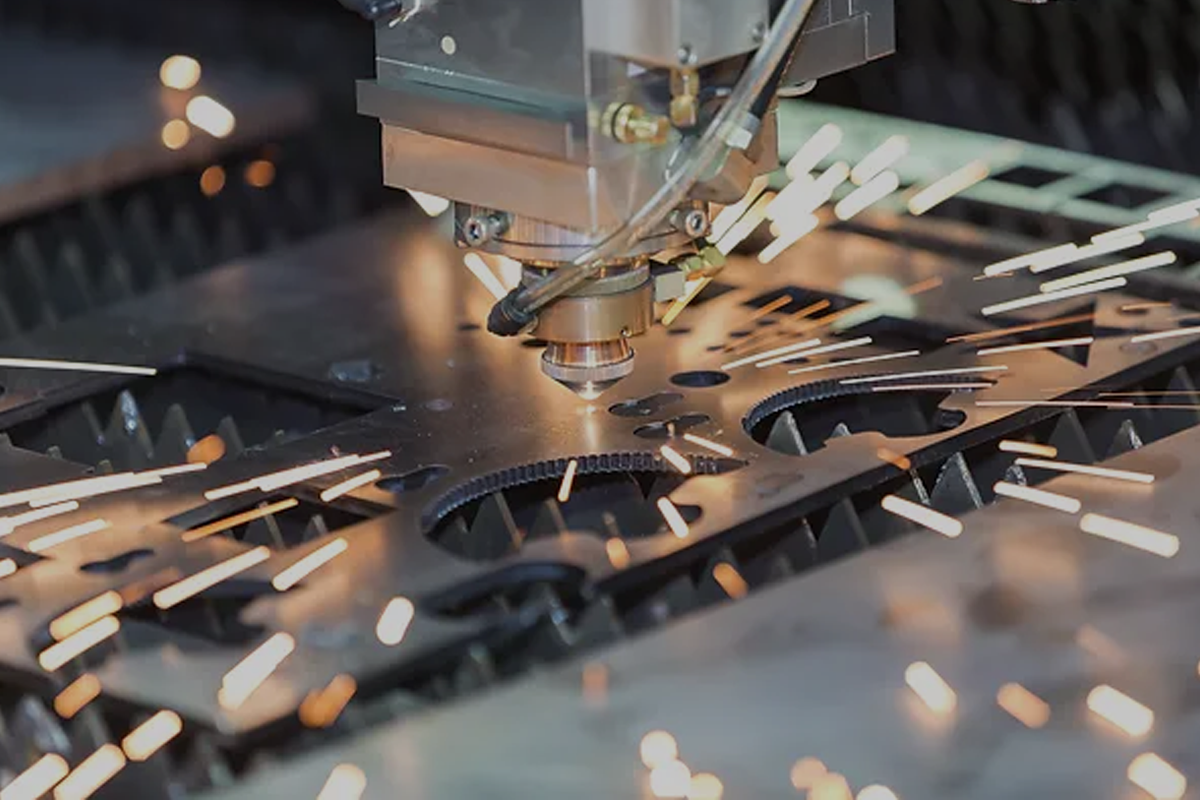

Fiber laser cutter

The fiber laser machine converts electricity into light through the SPI/IPG laser, then irradiates the high-energy laser beam onto the surface of the blank piece through the cutting head, vaporizing the irradiated material instantly.

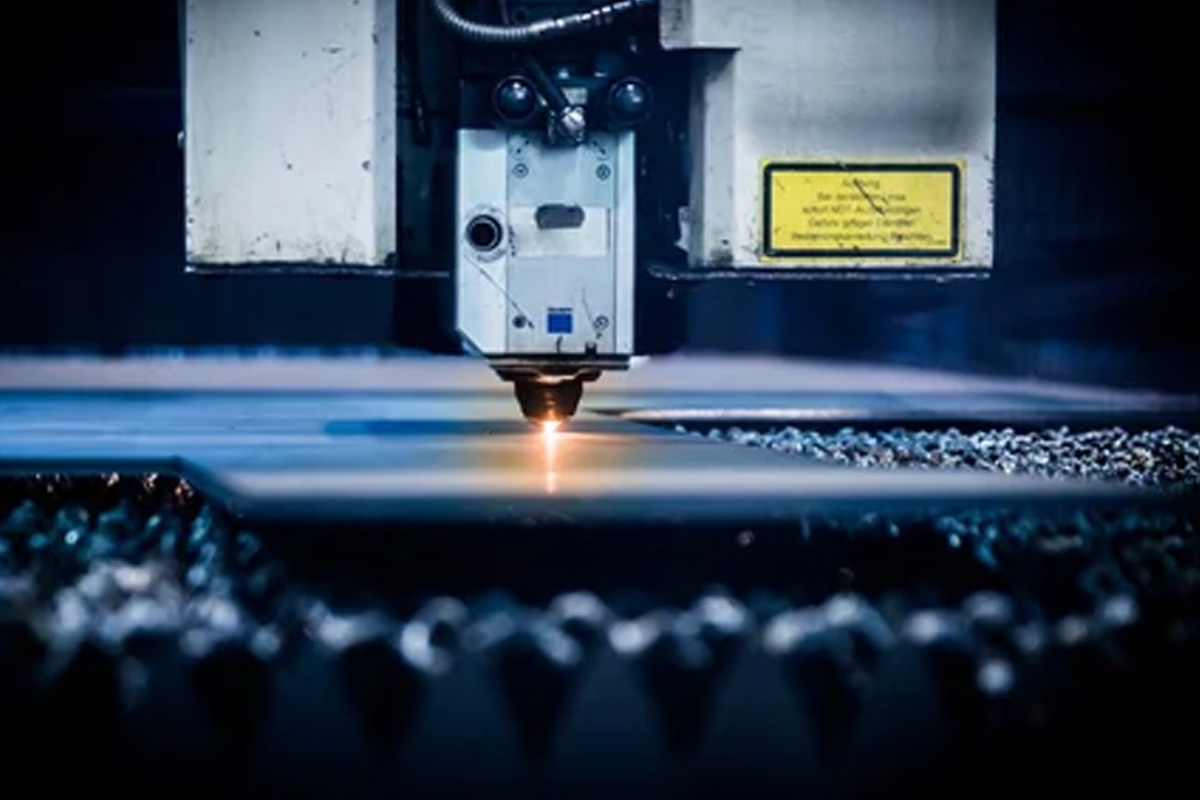

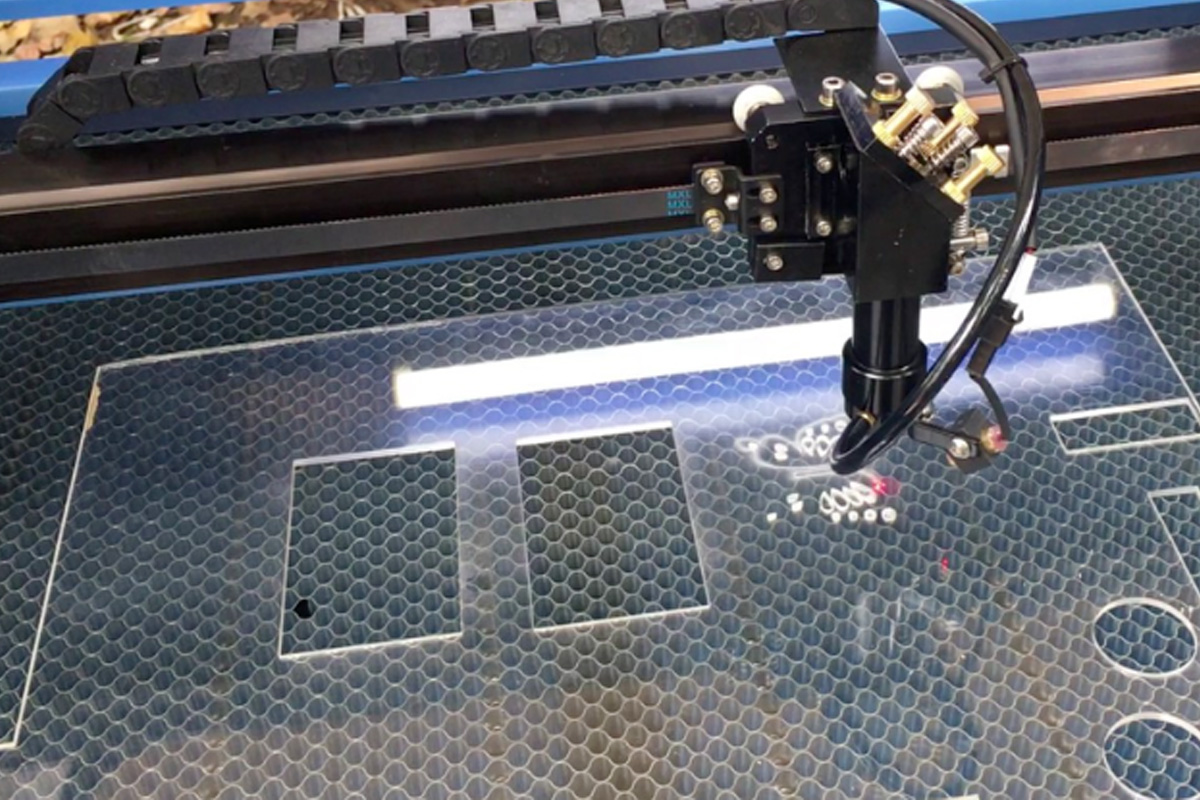

CO2 laser cutter

The CO2 laser cutter uses CO2-based gas to generate a laser beam to cut or engrave materials. In this cutting process, auxiliary gas such as oxygen or argon is used to increase cutting speed and clean the material surface.

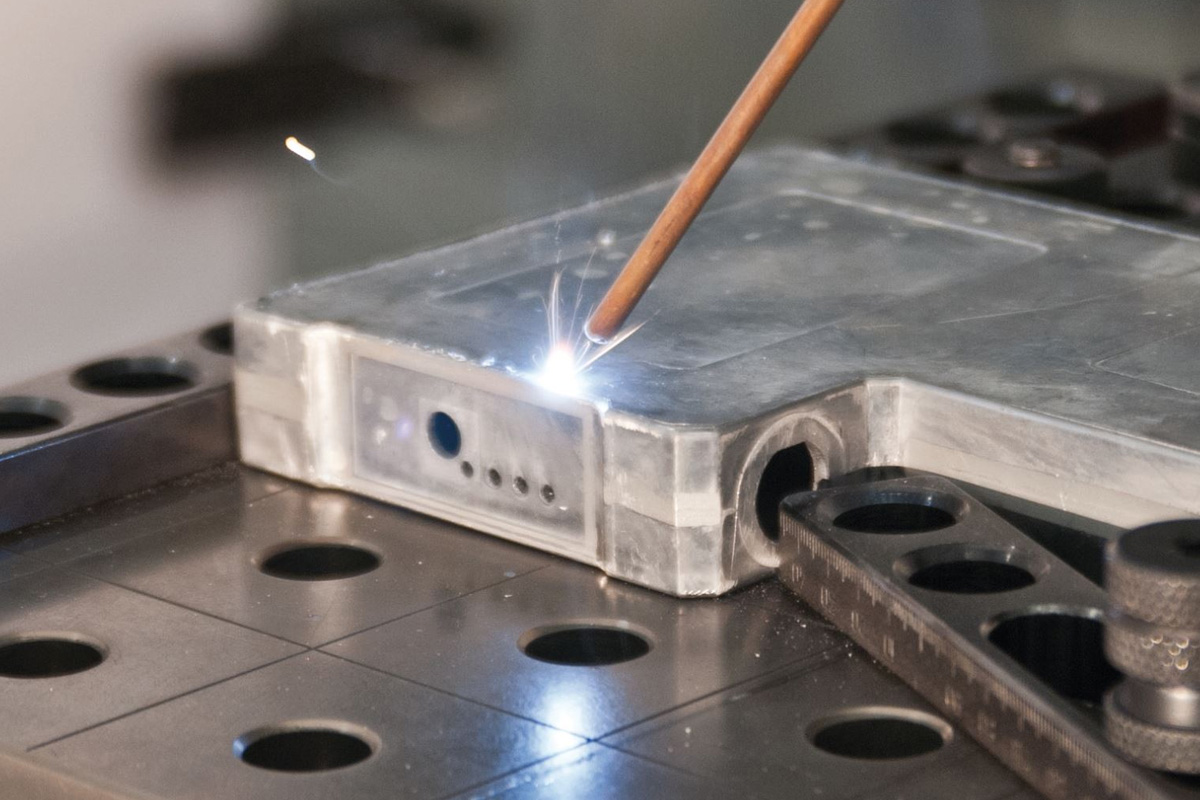

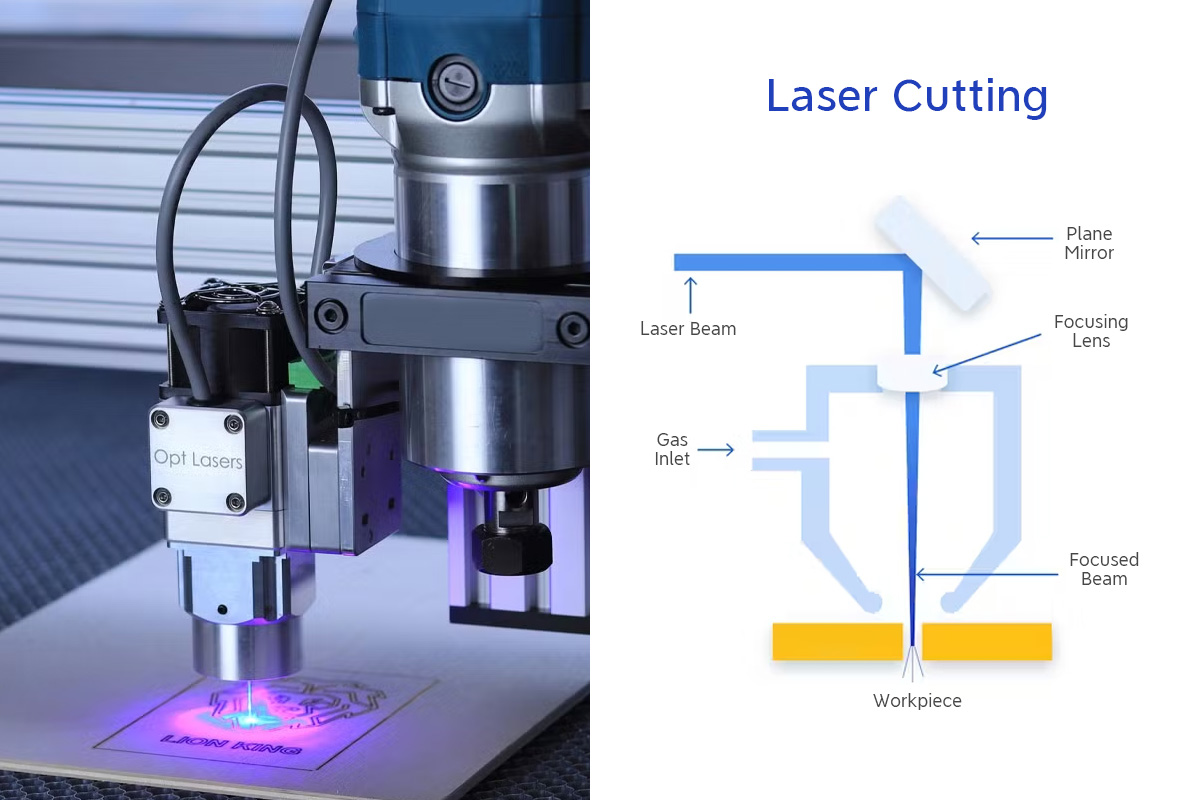

Crystal laser cutter

Crystal laser cutting machines use Nd: YAG (neodymium-doped yttrium aluminum garnet) and Nd: YVO (neodymium-doped yttrium vanadate), usually the former is more commonly used, to generate laser beams to cut and engrave materials.

Why Choose Our Laser Cutting Service

Precision and Accuracy

Our latest laser cutting machines offers high accuracy, with tolerances as tight as 0.1mm. This means every part is cut exactly to your specifications, minimizing waste and maximizing production efficiency.

Wide Material Compatibility

We cut a wide variety of metals, including stainless steel, mild steel, aluminum, copper, and brass. The laser cutting service will take into consideration the different thicknesses and complex geometries to offer you versatility in your designs.

Fast Turnaround

With our automated systems and streamlined processes, we can deliver custom metal parts quickly without compromising quality. In a hurry for parts? Our laser-cutting service ensures fast and efficient production.

Engineering Support

Our engineering team turns design challenges into viable solutions. We provide hands-on support to make sure your custom laser cutting projects receive the best technical advice and design optimization.

Laser Cutting Capabilites and Tolreances

Description |

General Tolerance |

|---|---|

|

Material Thickness |

Thickness tolerances are determined by the material blank. Carbon steel < 25 mm (0.98 in.), Stainless steel < 15 mm (0.59 in.), Aluminum < 15 mm (0.59 in.) , Copper < 12.7 mm (0.5 in.) |

|

Maximum Part Size |

10 mm (0.40 in.) |

|

Minimum Part Size |

2X material thickness with a minimum of 1 mm (0.04 in.) |

|

Kerf (slit size) |

About 0.5 mm (0.02 in.) |

|

Edge Condition |

Laser cut edges have matte and vertical lines. |

|

Reapability |

+/- 0.05 mm (0.002 in.) |

|

Positioning Accuracy |

+/- 0.10 mm (0.004 in.) |

Laser Cuttable Materials

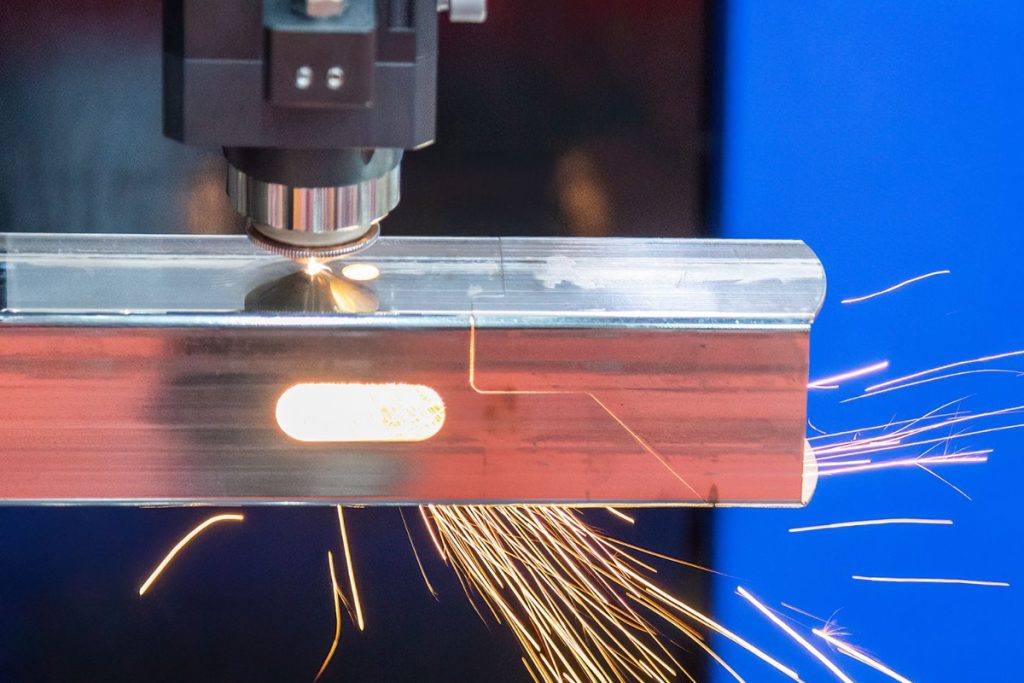

Metal Laser Cutting

Our metal laser cutting service supports a wide range of metal materials, including stainless steel, aluminum, mild steel, and copper. We also work with various grades of these metals, catering to different thicknesses and specifications.

Plastic Laser Cutting

Our Plastic cutting services facilitate a variety of materials, including but not limited to acrylic, and polycarbonate. We can cut these various materials to the exact dimensions needed thin sheets or a thicker, more rigid plastic component.

Wood Laser Cutting

We offer high-quality wood laser cutting services. We offer a variety of wood materials, including pine, oak, and maple. Each type provides a unique aesthetic and can be used for both structural purposes and intricate decorative works.

What is Laser Cutting?

Laser cutting is a method of cutting or engraving material by using a focused laser beam. The laser melts, burns, or vaporizes the material to create clean and accurate cuts with minimum heat-affected zones. This technology is well adapted for the cutting of various materials, including metals, plastics, wood, and composites. Laser cutting is a perfect method for applications requiring great precision, detailed designs, and high repeatability.

Whether it’s thin sheets or thicker materials, laser cutting provides sharp, smooth edges with tight tolerances, perfect for both small runs and large-scale production. With the latest in laser technology, we are able to ensure that every part is cut to your exact specifications for consistent quality and quick turnaround times.

Advantages of Laser Cutting

Laser cutting provides numerous benefits that make it a preferred method for many industries. Here are some key advantages of using laser cutting:

- Minimal Heat Impact. Unlike traditional cutting methods, laser cutting generates less heat, minimizing thermal distortion and warping of the material. This results in clean, precise cuts without affecting the material’s integrity.

- Reduced Material Waste. With the laser’s narrow kerf, material waste is minimized, making laser cutting an efficient and cost-effective solution for projects where material conservation is a priority.

- Smooth and Clean Edges. Laser cutting produces smooth, burr-free edges that typically require little to no finishing, reducing the need for secondary processes like sanding or polishing.

Serving Multiple Industries

Our rapid prototyping and on-demand production services are used across a wide range of industries, but the following areas are where we have the most experience.

Medical

Elevate the reliability of your medical devices with accurate manufacturing solution.

Aerospace

Lightweight and durable solutions for the most demanding aviation needs.

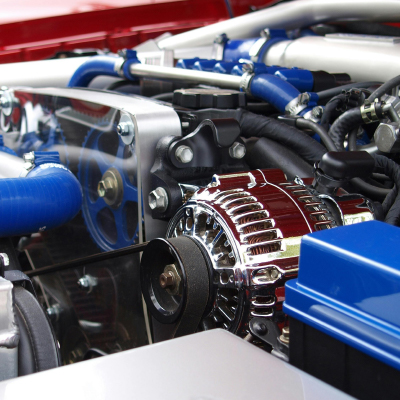

Automotive

Tailored to optimize performance and reliability in the automotive.

Robotics

Fuel your robotic innovations with our precision-engineered parts.