Custom CNC Turning Service

SogaWorks offers advanced CNC turning services that can produce both simple and complex cylindrical geometries at a lower cost.

- Tight tolerance up to ±0.005mm

- 3, 4, 5 axis CNC miliing for complex geometries

- A broad range of metals, plastics available

- Affordable, reliable solutions with fast turnaround

Start A CNC Turning Quote

STEP I STP I SLDPRT I PRT I IPT I DWG I PDF I DXF I ZIP I RAR

All drawings are secure and confidential.

CNC Turning Capabilities

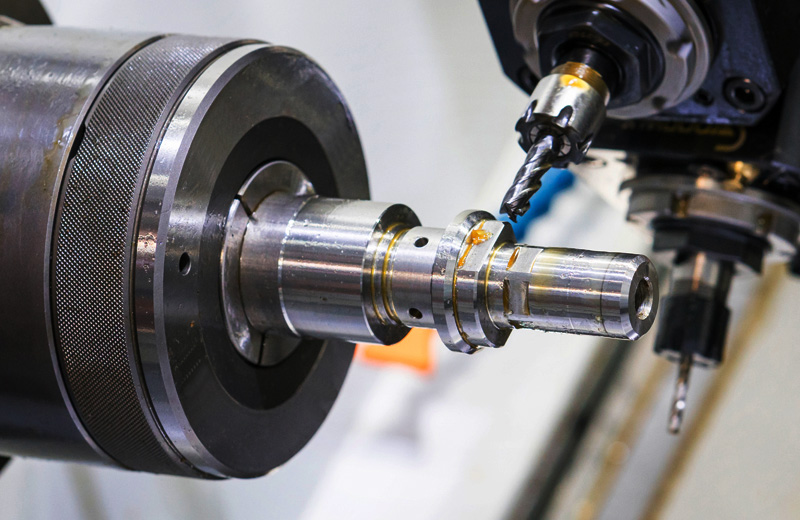

Make use of the custom CNC turning service and get reliable, high-precision turned parts for your unique project needs. Our advanced CNC turning services can produce both simple and complex cylindrical geometries at a low cost. By using dynamic tooling we can produce precise geometries for complex features such as axial and radial holes, slots, grooves and flat surfaces.

By Building a manufacturing network comprising over 1,000 shops, SogaWorks can provide CNC turning services with quick turnaround times and affordable prices. Our platform uses AI technology to offer instant pricing and DFM feedback, ensuring that your parts are optimized for the CNC turning process. Whether you need rapid prototypes or low-to-high volume production runs, SogaWorks delivers you high-quality metal and plastic CNC turned parts.

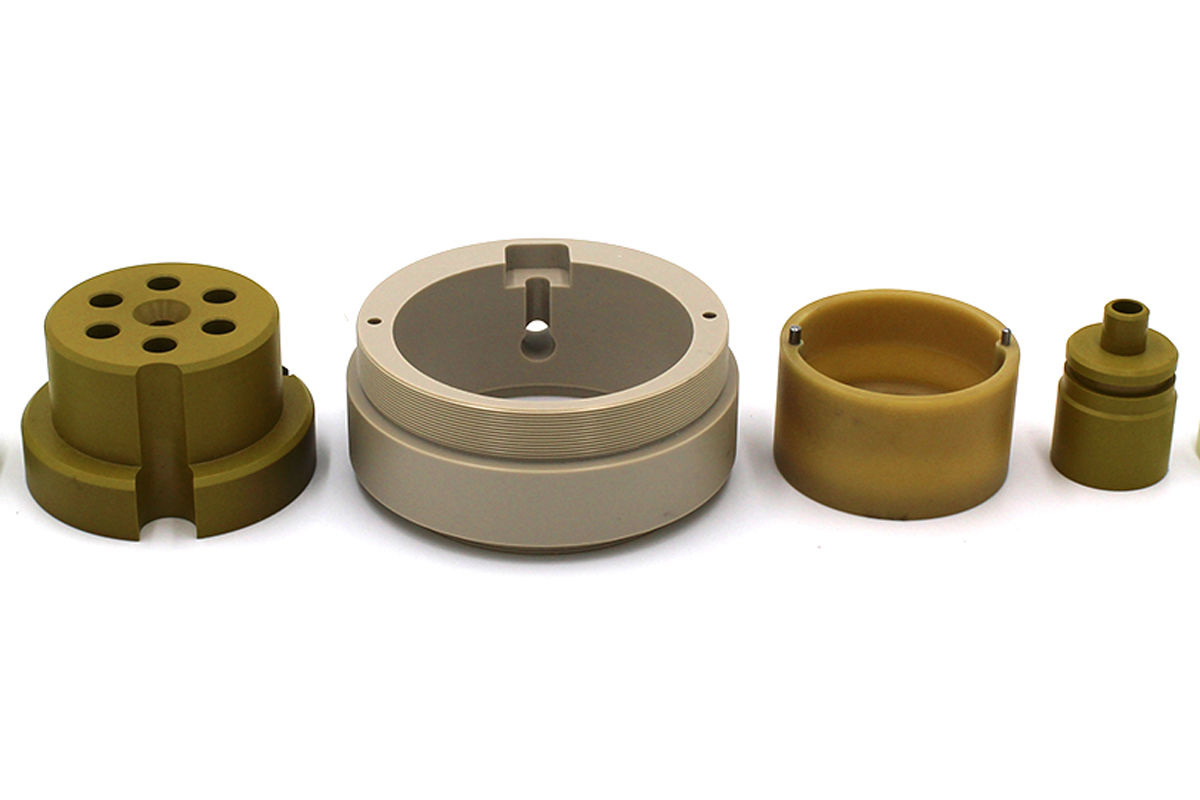

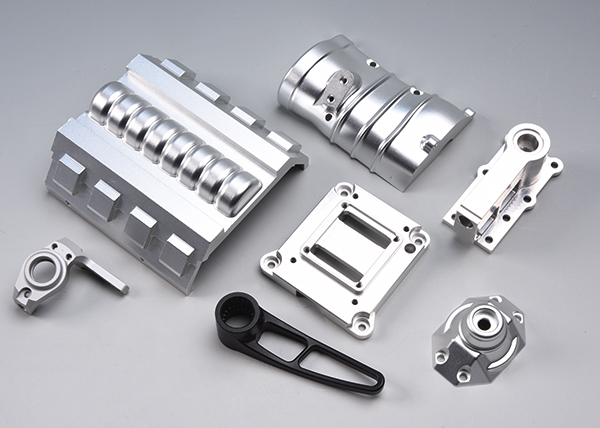

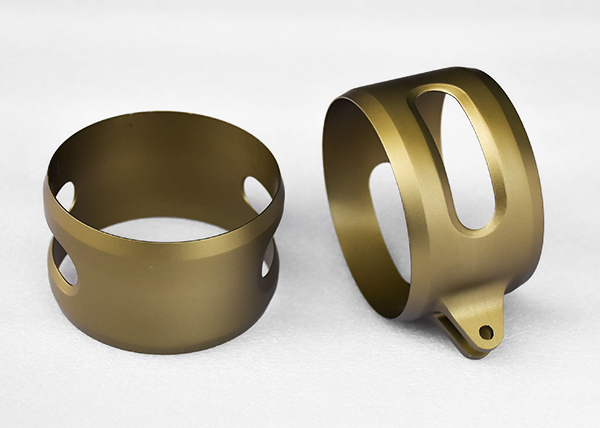

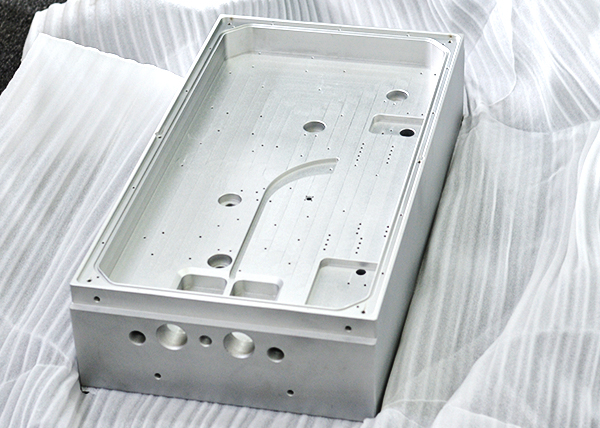

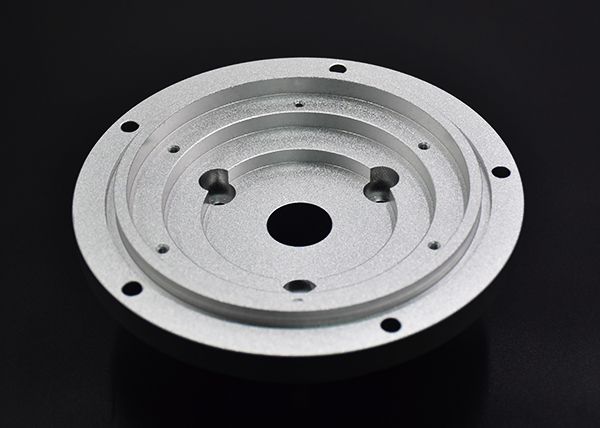

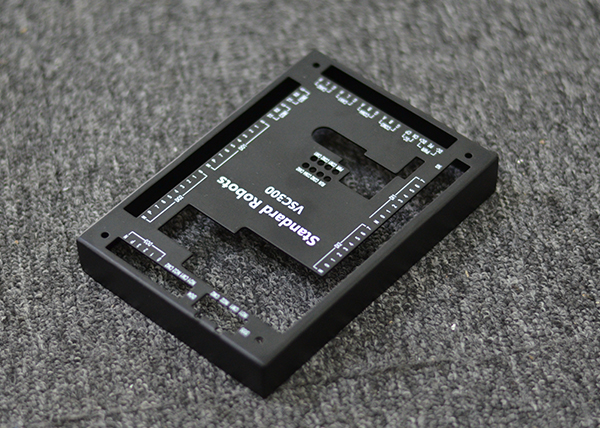

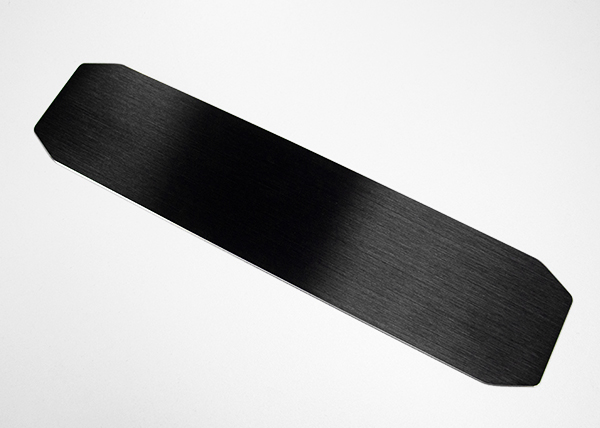

CNC Turning Parts Produced By SogaWorks

We produce precision CNC turned prototypes and end-use parts for our valued customers.

CNC Turning Tolerance

If not otherwise specified on the technical drawing, all parts will be machined to ISO 2768 tolerance standards below. Generally, you can choose ISO 2768-m, ISO 2768-f or specify much tighter tolerances in your 2D technical drawings.

Limits for nominal lengths |

ISO 2768-m |

ISO 2768-f |

|---|---|---|

|

0.5mm to 3mm |

±0.1mm |

±0.05mm |

|

Over 3mm to 6mm |

±0.1mm |

±0.05mm |

|

Over 6mm to 30mm |

±0.2mm |

±0.1mm |

|

Over 30mm to 120mm |

±0.3mm |

±0.15mm |

|

Over 120mm to 400mm |

±0.5mm |

±0.2mm |

|

Over 400mm to 1000mm |

±0.8mm |

±0.3mm |

|

Over 1000mm to 2000mm |

±1.2mm |

±0.5mm |

|

Over 2000mm to 4000mm |

±2.0mm |

- |

Limits for nominal lengths |

ISO 2768-m |

ISO 2768-f |

|---|---|---|

|

Up to 10mm |

±1° |

±1° |

|

Over 10mm to 50mm |

±0°30′ |

±0°30′ |

|

Over 50mm to 120mm |

±0°20′ |

±0°20′ |

|

Over 120mm to 400mm |

±0°10′ |

±0°10′ |

|

Over 400mm |

±0°05′ |

±0°05′ |

Limits for nominal lengths |

ISO 2768-m |

ISO 2768-f |

|---|---|---|

|

0.5mm to 3mm |

±0.2mm |

±0.2mm |

|

Over 3mm to 6mm |

±0.5mm |

±0.5mm |

|

Over 6mm |

±1.0mm |

±1.0mm |

Roughness and threads

CNC Turning Materials

CNC Turning Metals

SogaWorks provides 50+ metals and grades for your CNC milling parts selection, including aluminum 7075, 6061, stainless steel 304, 316, copper and more.

CNC Turning Plastics

SogaWorks provides 20+ metals and grades for your CNC milling parts selection, including ABS, POM, acrylic, PC and others.

CNC Turning Surface Finishes

Surface finishes are crucial for achieving the desired functional or aesthetic quality of CNC machined components. At SogaWorks, we offer a spectrum of surface finishes to enhance your parts’ function by improving hardness, roughness, corrosion and heat resistance.

Grow a thickness oxide layer ranging from 0.0001 to 0.001 inches to protect and color aluminum CNC machined parts for corrosion resistance and aesthetics.

Anodizing Type II

Create a thicker layer ranging from 0.001 to 0.004 inches. it is ideal for where hardness and wear resistance are crucial.

Anodizing Type III

Preserve or enhance the electrical conductivity of the aluminum parts while still providing the benefits of traditional type II.

Conductive Anodizing Type II

Cover a part with a thin layer of metal by electrochemical deposition for function, decoration or corrosion resistance.

Electroplating

Apply a protective coating of zinc to steel, iron, and copper objects to prevent corrosion.

Galvanizing

Apply a protective or functional coating to surfaces. It involves the application of liquid paint and then undergoes a curing process to solidify the paint film.

Painting

Apply a protective and decorative coating to materials, primarily metals. It involves applying a dry powder onto a surface, which is then applied electrostatically and cured under heat or UV light.

Powder Coating

Spray silica sand to the surface of the workpiece using compressed air to clean, smooth, or texture surfaces, providing a desired finish for functional or aesthetic purposes.

Sand Blasting

Apply images, patterns, or text to surfaces.

Silk Screen

A conversion coating applied to ferrous metals to provide a thin, protective layer of black iron oxide.

Black Oxide

Use abrasive belts or roller brushes to refine and improve the surface quality of components.

Brushing

Selectively remove material from the surface, resulting in a smooth, polished, and often corrosion-resistant finish.

Electropolishing

CNC Turning Design Guidelines

Review the recommended and practical guidelines for the most common features found in CNC turned parts.

Features |

Recommended |

Feasible |

|---|---|---|

|

Max. size |

- |

500 mm in diameter |

|

Min. Feature |

Ø 2.5 mm |

Ø 0.5 mm |

|

Internal edges |

R 8mm |

R 0.25mm |

|

Min. wall thickness |

0.8 mm (for metals) |

0.5 mm (for metals) |

|

Holes |

Diameter: standard |

Diameter: Ø 0.5 |

|

Threads |

Size: M6 or larger |

Size: M2 |

How Does CNC Turning Works?

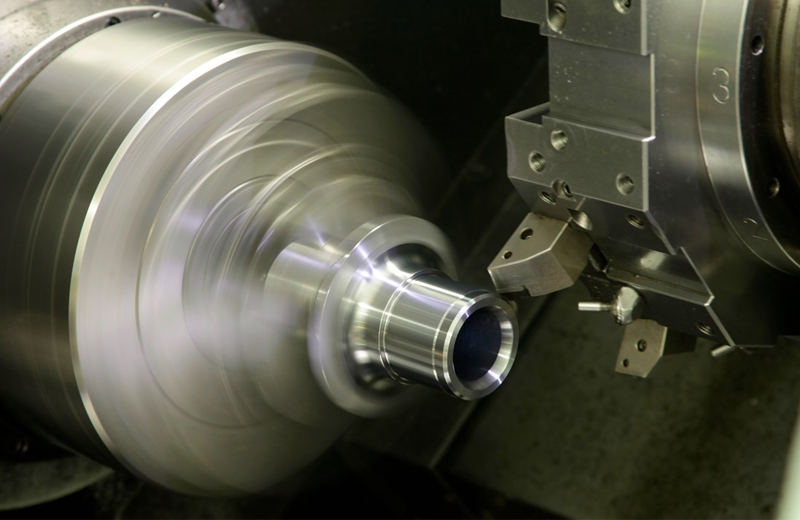

CNC turning is a subtractive manufacturing process that employs computer-controlled lathes to accurately shape materials into cylindrical components. The process begins with designing the part using CAD software, which is then translated into instructions for the CNC machine through CAM software. During the setup phase, the appropriate cutting tools are installed, and a cylindrical workpiece is secured in the machine’s chuck, which holds and rotates the material.

As the machine operates, the workpiece spins at high speeds while the cutting tools traverse along various axes, carving and shaping the material according to the programmed specifications. This stage includes operations such as facing, threading, knurling, and drilling. To prevent overheating and remove debris, a coolant is typically applied.

Once machining is complete, the part may undergo additional finishing processes, such as sand blasting or polishing. The final step involves a comprehensive inspection to ensure that the part adheres to all required dimensions and tolerances.

Serving Multiple Industries

Our rapid prototyping and on-demand production services are used across a wide range of industries, but the following areas are where we have the most experience.

Medical

Elevate the reliability of your medical devices with accurate manufacturing solution.

Aerospace

Lightweight and durable solutions for the most demanding aviation needs.

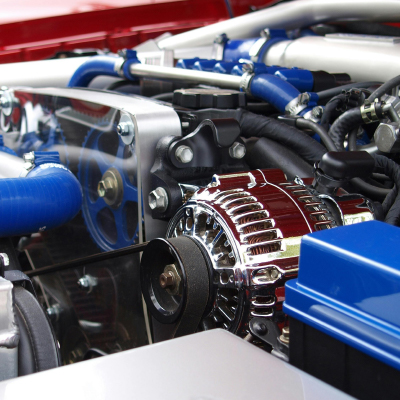

Automotive

Tailored to optimize performance and reliability in the automotive.

Robotics

Fuel your robotic innovations with our precision-engineered parts.