With SogaWorks Network, you get access to a network of experienced, specialized manufacturers selected for operational excellence.

Our network gives you next-gen supply chain resiliency and agility. We work with a highly vetted network of more than 1000 manufacturing partners and hold each of them to high quality standards. we are staffed with quality engineers, logistics managers,

and manufacturing engineers to ensure quality at the source.

Fill out our registration form, and you will get a supplier account.

SogaWorks conducts internal assessments to check if suppliers meet our qualification standards. The assessment dimensions include registration and licensing, manufacturing capabilities, quality control, customer confidentiality, etc.

We will send a test order to the supplier, and the quality and delivery time of the test order are consistent with customer expectations. This helps suppliers understand our requirements and how our platform works.

After the first order test, the supplier can access orders on our platform. In the first 90 days, if the quality and lead time of orders meet our requirements, the supplier can access all types of SogaWorks orders.

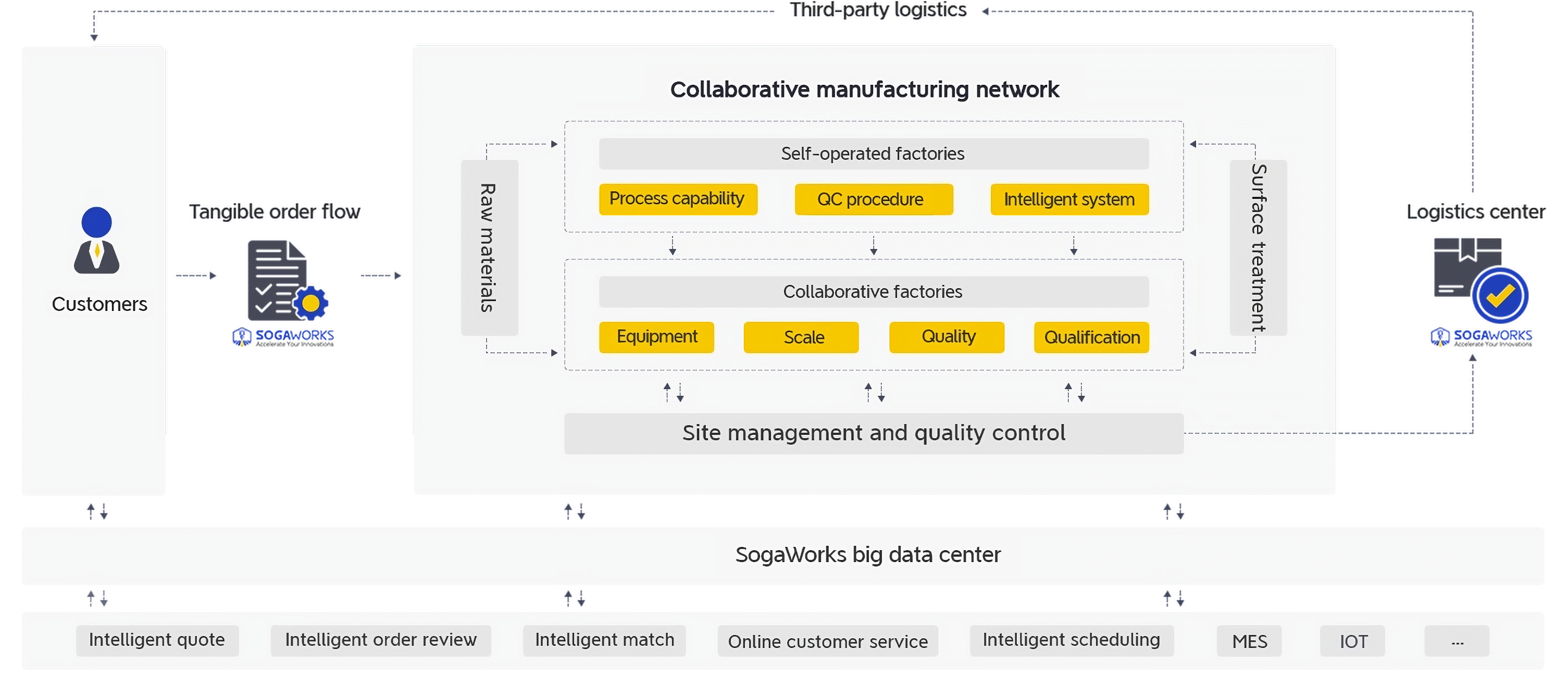

We believe that only a complete workflow is an effective means to ensure quality. SogaWorks builds a distributed manufacturing network with self-operated core factories and collaborative partner factories to achieve efficient and cost-effective on-demand production.

A strong supplier network enables us to offer a range of capabilities to meet our custom needs from prototyping to end-use product production. We offer CNC machining, sheet metal fabrication, urethane casting, injection molding, industrial-grade metal and plastic 3D printing and more.

Combining the AI-driven automatic quotation system with a wide range of supplier capabilities, we can provide customers with competitive pricing and fast delivery.

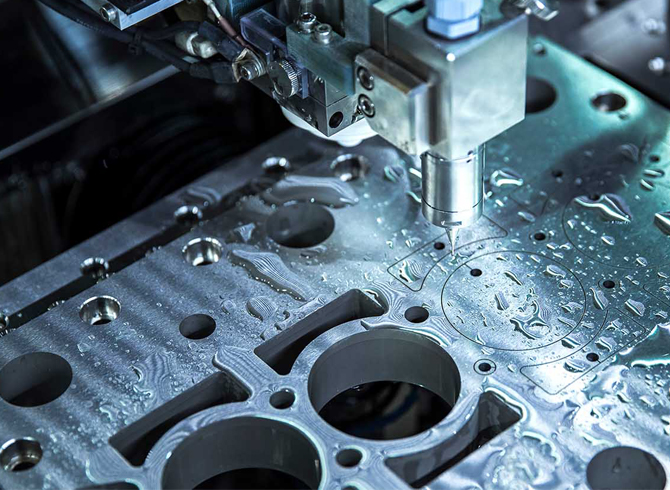

By integrating excellent Chinese manufacturers, we can provide a range of high-end equipment, including 4/5-axis CNC machining centers, and industrial 3D printers. These pieces of advanced equipment not only improve machining accuracy and efficiency but also ensure the production quality of complex parts and precision components.

We are committed to providing a wide range of finishing services. Whether you need to enhance the durability of parts, improve their appearance quality, or ensure their performance in harsh environments, we can provide you with professional solutions.

Robotics

Bio-medical industry

Optoelectronic technology

Aerospace

Intelligent equipment

Automation

Instrumentation

UAV

Other hardware

Universities/research institute

Address:

Room 101-117(the entire 1st floor), 2nd Building,

Tianxin Industrial Zone, Guxing Community, Xi’xiang Street,

Bao’an District, Shenzhen, China. 518126