Electropolishing Service

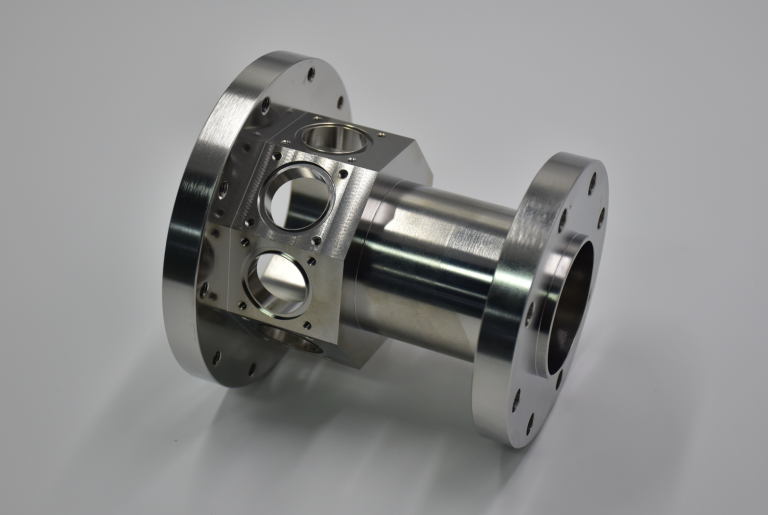

Explore our electropolishing service to polish and deburr metal parts, obtaining a smooth and shining surface.

Electropolishing Specification

We provide quality electropolishing service for aluminum, stainless steel and copper components with different electrolytic solutions. Our electropolishing processes dissolve burrs faster and result in smooth and clean surfaces with a lustrous finish.

Materials |

Color |

Visual Appearance |

Aluminum, Stainless steel, Copper, Brass |

Natural |

Shiny, smooth finish |

|---|

Advantages

- It brings a bright shiny finish that is visually appealing

- Reduces roughness by leveling micro-peaks and valleys

- Extends the fatigue life of metal parts by removing surface imperfections

Notes

- You cannot eliminate obvious processing marks after electropolishing

- Electropolishing is more expensive than mechanical polishing methods

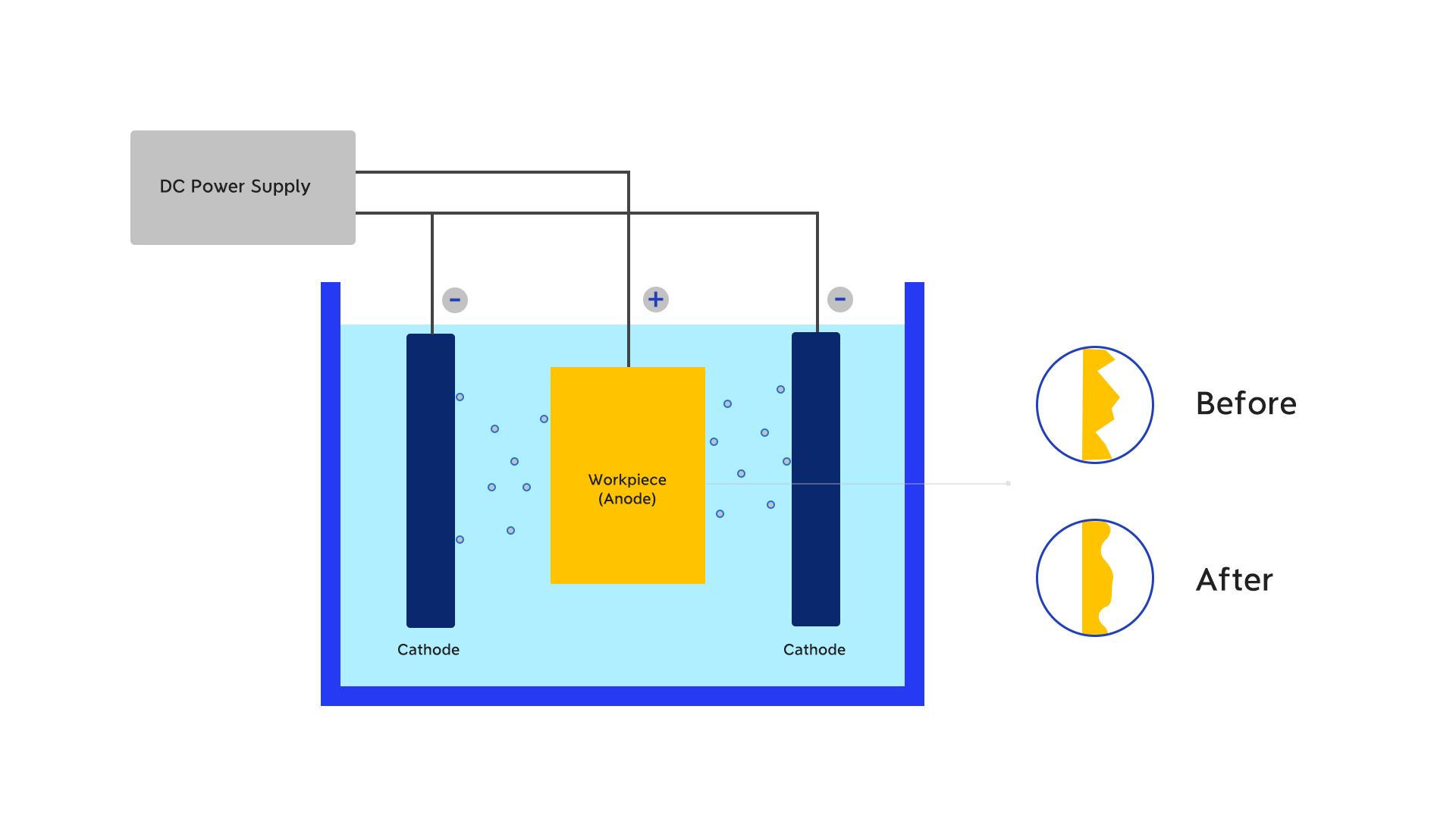

Electropolishing Process

The workpiece is used as the anode and connected to the positive pole of the DC power supply. A conductive material resistant to electrolyte corrosion is used as the cathode and connected to the negative pole of the DC power supply.

The workpiece and the cathode material are immersed in the electrolyte (sulfuric acid and phosphoric acid as the main solution) at a certain distance. Under certain temperature, voltage and current density conditions, the tiny protrusions on the surface of the workpiece begin to dissolve and gradually become a smooth and bright surface.